Dynamic model solution method for one-dimensional plug flow reactor

A technology of plug flow reactor and dynamic model, which can be used in instruments, CAD numerical modeling, special data processing applications, etc., and can solve problems such as error in solution results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

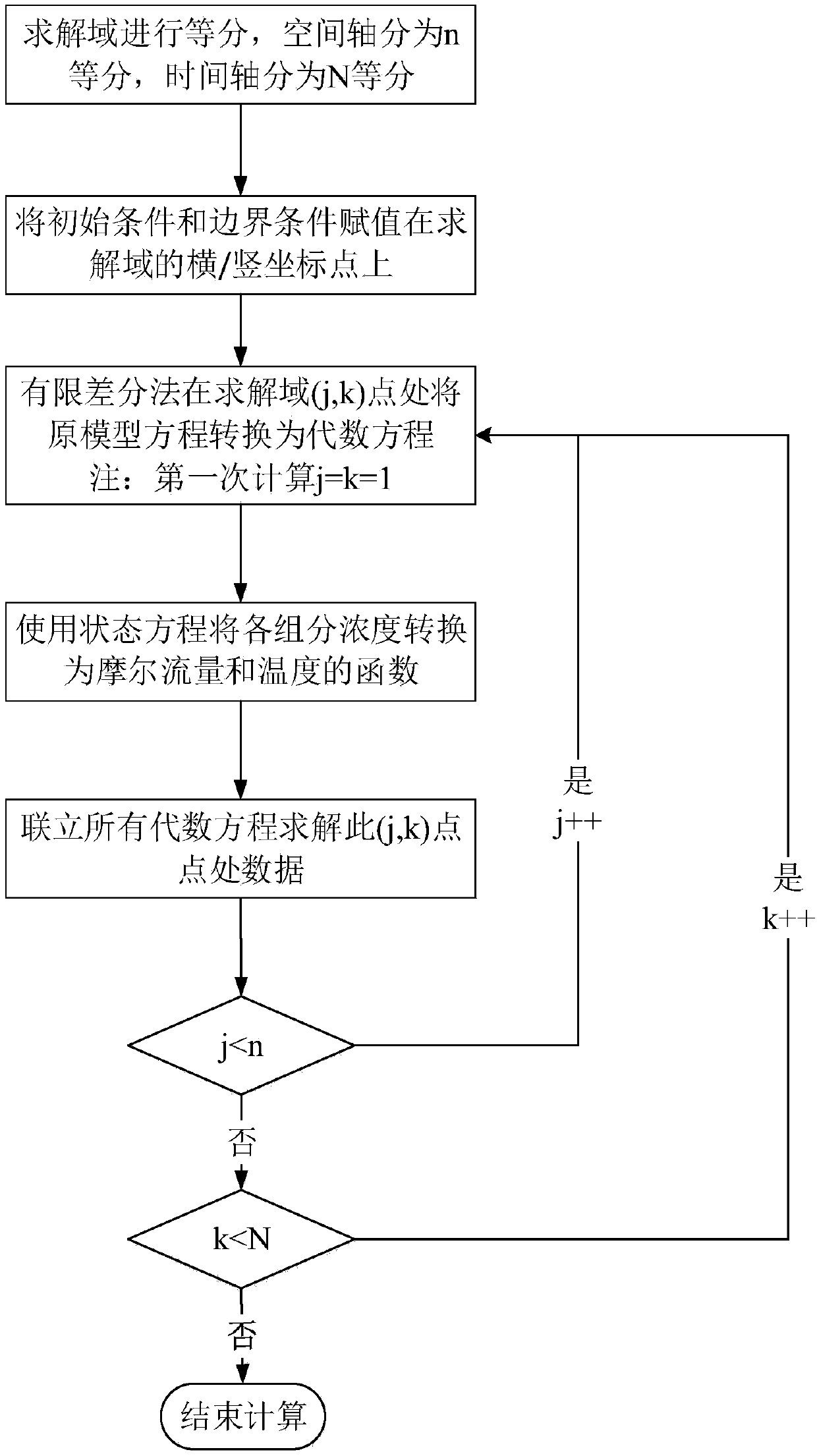

[0042] see figure 1 As shown, a method for solving the dynamic model of a one-dimensional plug flow reactor that is applicable to a gas feedstock of the present invention includes:

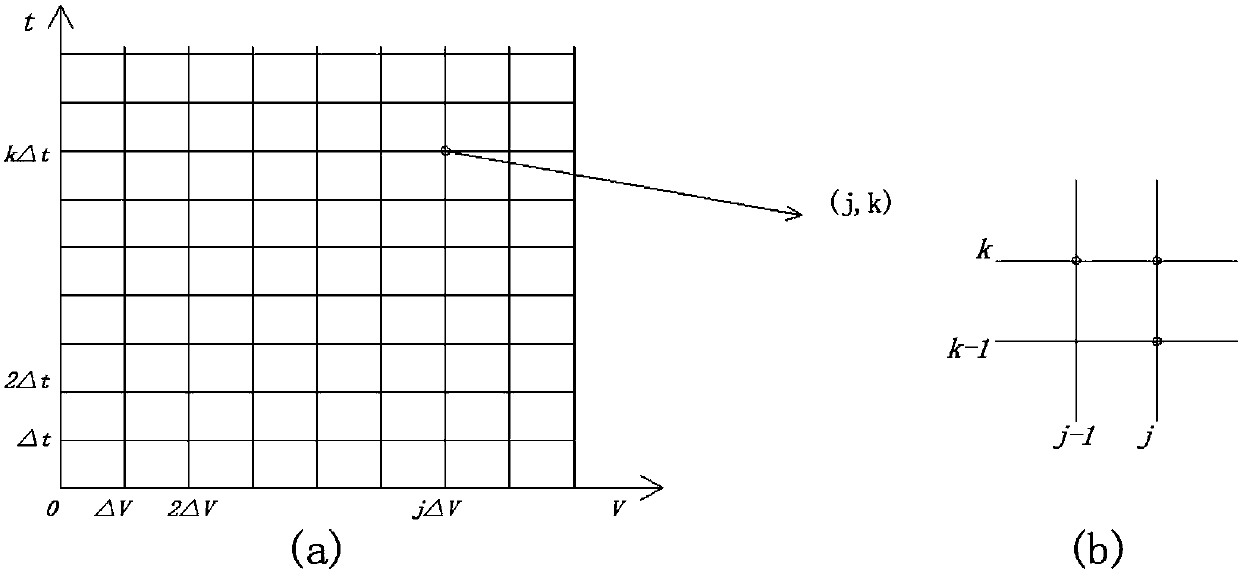

[0043] Step 10, see figure 2 As shown, according to the size of the reactor and the calculation time, the solution domain is equally divided, the space axis is divided into n equal parts, and the time axis is divided into N equal parts; where figure 2 (a) is the overall segmentation diagram that equally divides the solution domain, figure 2 (b) is the segmentation map at point (j,k);

[0044] Step 20, assigning initial conditions and boundary conditions to coordinate points corresponding to the abscissa and ordinate on the solution domain;

[0045] Step 30, using the finite difference method to convert the original model equation into an algebraic equation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com