Tree search method and device for homosequential assembly line workshop scheduling problem

A technology of workshop scheduling and search method, applied in the direction of instruments, calculation models, data processing applications, etc., can solve the problems of non-reproducible results, instability, long calculation time, etc., to enhance flexibility and reliability, and improve production efficiency , the effect of shortening the maximum completion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

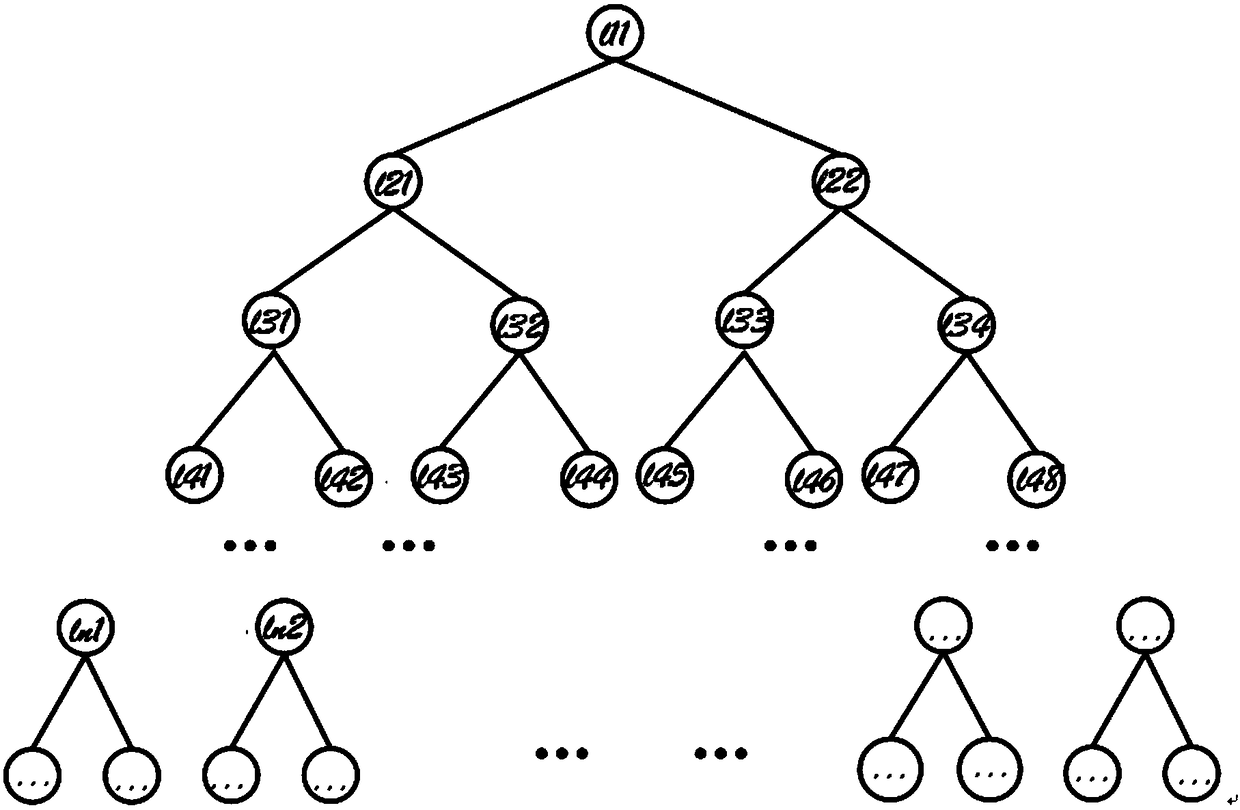

[0040] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

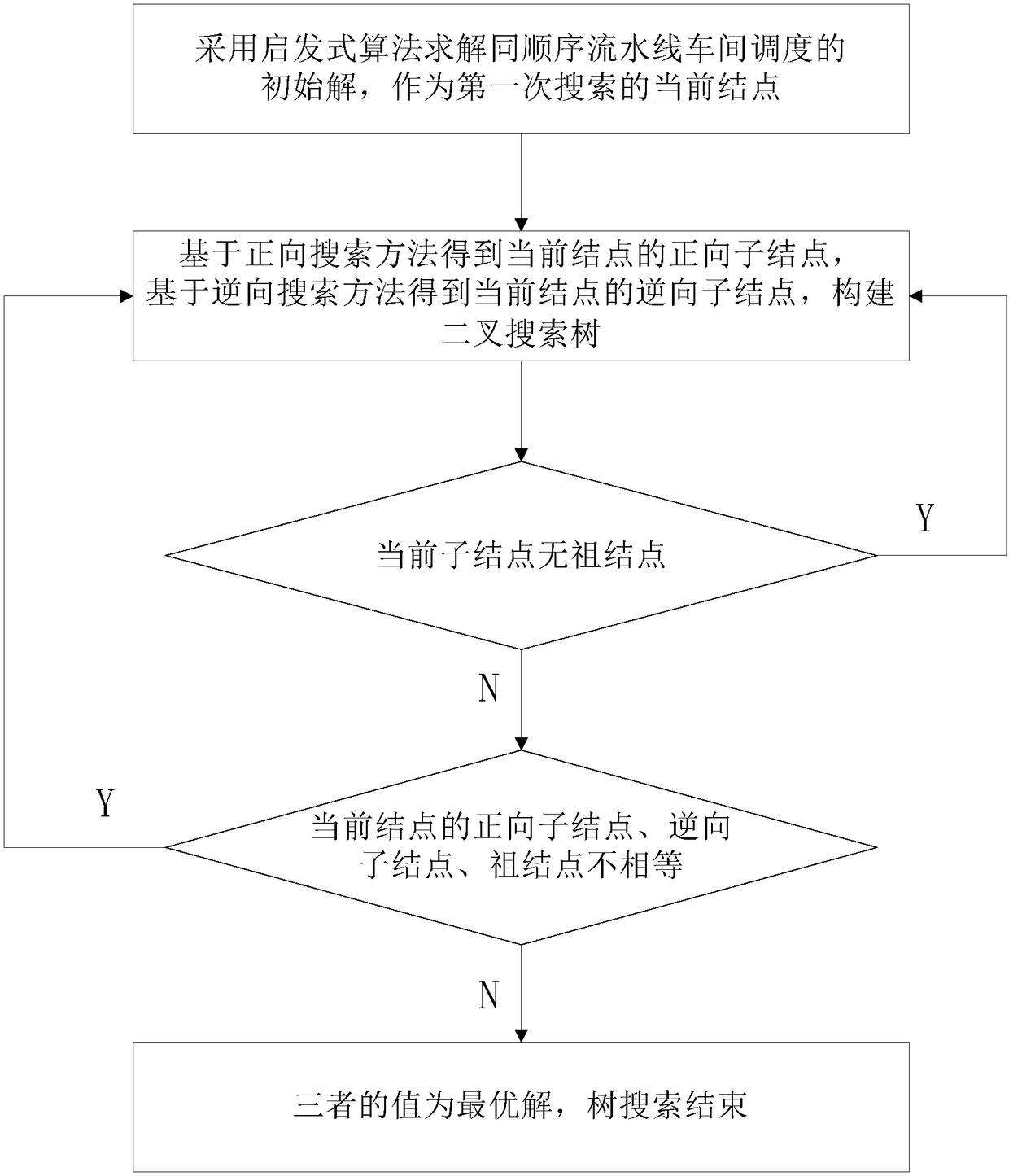

[0041] The workshop scheduling problem means that the scheduled workpieces need to be processed on different machines. Each machine can only process one workpiece at most at the same time, and each workpiece can only be processed on one machine at most at the same time. The processing of workpieces is not allowed. Interruption, the problem is to determine the processing sequence and timing of workpieces on the machine so that the objective function is optimized. Workshop scheduling problems widely exist in manufacturing and logistics systems. The solving methods mainly include tabu search algorithm, simulated annealing algorithm, ant colony al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com