Phase change material and foamy copper-based battery detection heat dissipation apparatus

A phase-change material and battery detection technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems that air cooling cannot be used for heat dissipation, the heat dissipation effect is not obvious, and cannot be promoted, so as to improve thermal uniformity, Easy to install and use, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

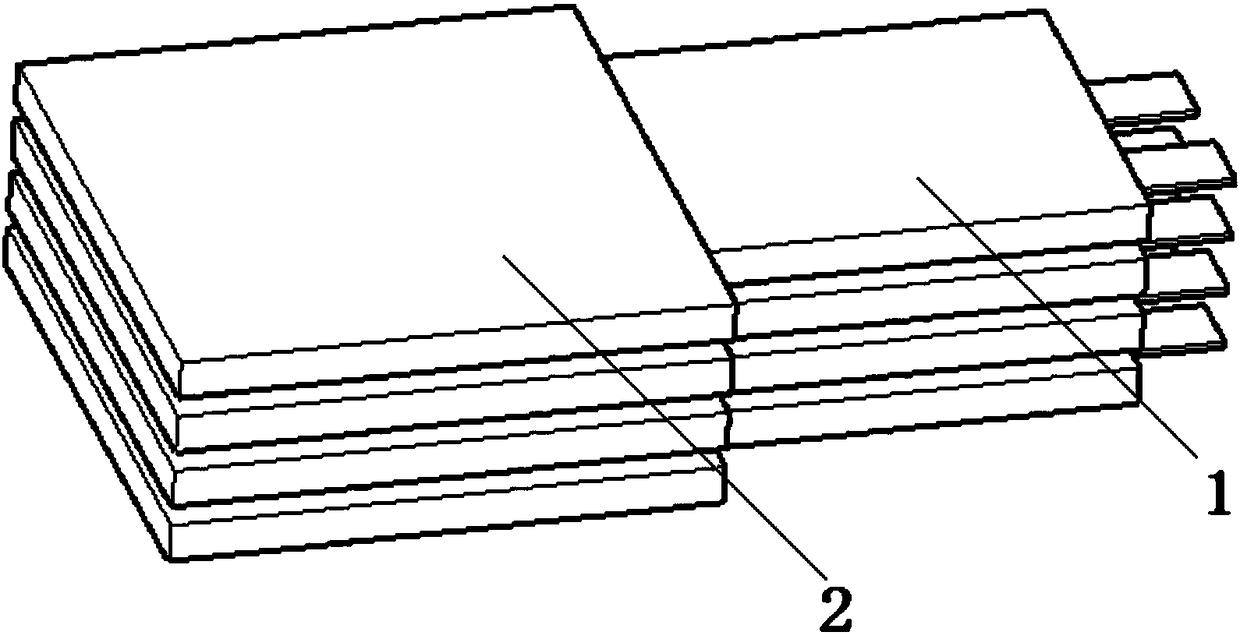

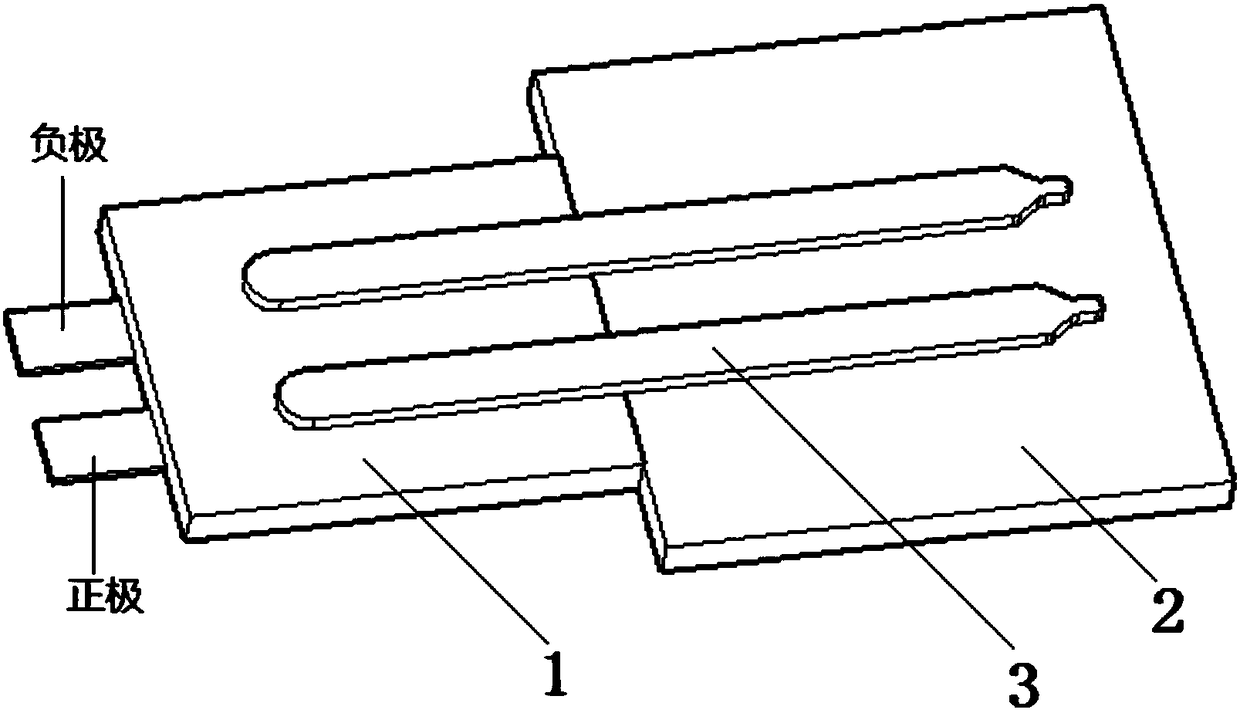

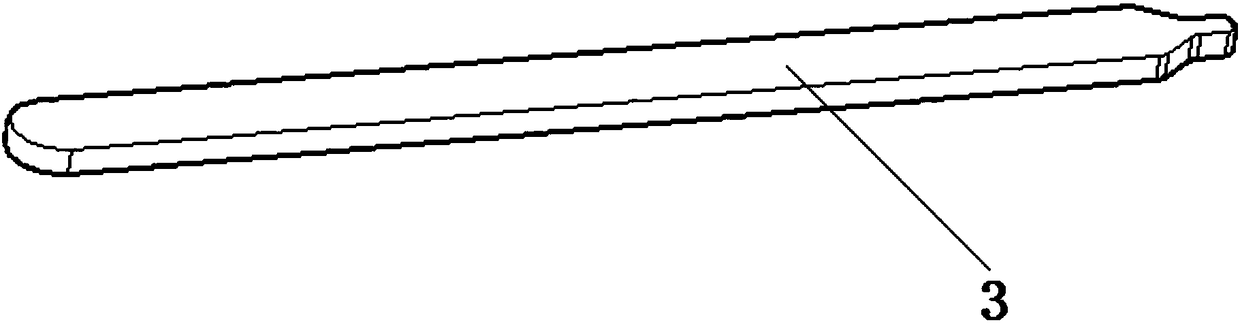

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it is a battery detection heat dissipation device based on phase change material and foamed copper shown in the present invention, which can accelerate the heat dissipation speed of the battery, improve the power performance of the battery and prolong the service life. The present invention includes a power lithium battery pack And polyurethane soft foam copper, polyurethane soft foam copper is filled with phase change material, preferably, phase change material is paraffin, and paraffin is to pressurize and fill in the polyurethane soft foam copper in the liquid state after melting, and polyur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com