Antenna oscillator

A technology of antenna element and element arm, which is applied in the field of communication antenna, can solve the problems that are not suitable for the development trend of low cost and automatic production in the communication technology industry, the difficulty of consistent size and shape, and the heavy weight of the cross element, etc., to achieve Ease of automation, reduced installation time, quick and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in combination with specific implementation methods and drawings.

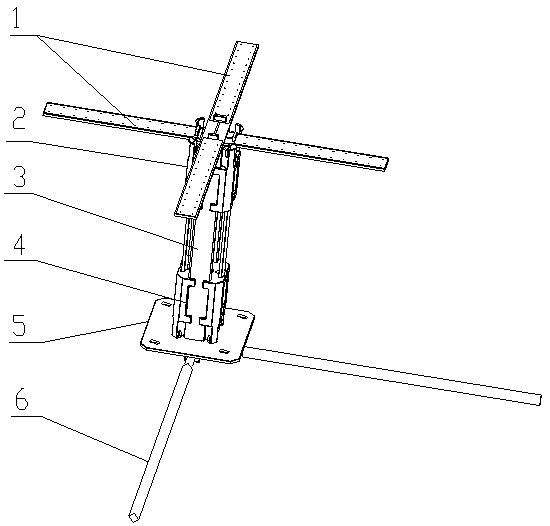

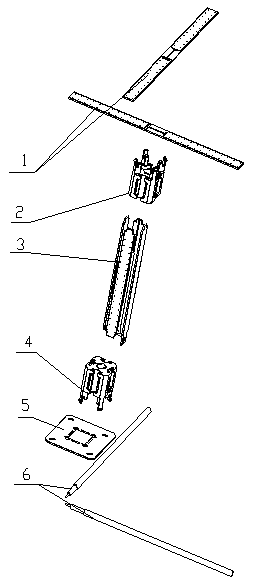

[0027] As shown in the figure, a specific implementation manner of an antenna element. It includes four supporting vertical pieces 3, two array arms 1 and a grounding piece 5.

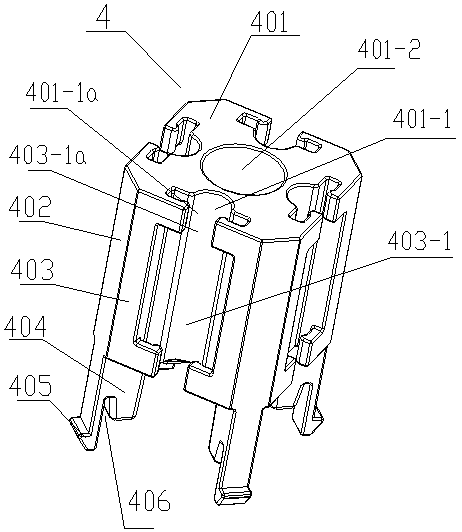

[0028] The four supporting vertical pieces 3 are arranged in a rectangular shape facing each other, the upper parts of the four supporting vertical pieces 3 are fixed to each other by the first plastic fixing piece 2, and the lower parts are fixed to each other by the second plastic fixing piece 4, and the two plastic fixing pieces are respectively provided with four The corresponding ends of the four support vertical pieces are inserted into corresponding slots; the upper ends of the four support vertical pieces 3 protrude from the slots of the first plastic fixture 2, and every two opposite support vertical pieces are connected to an elongated arm. 1. Two elongat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com