Flywheel energy storage system

A technology of flywheel energy storage and inertial flywheel, which is applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of single output voltage, charging and discharging cannot be carried out at the same time, and achieve the goal of improving power density, energy density and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

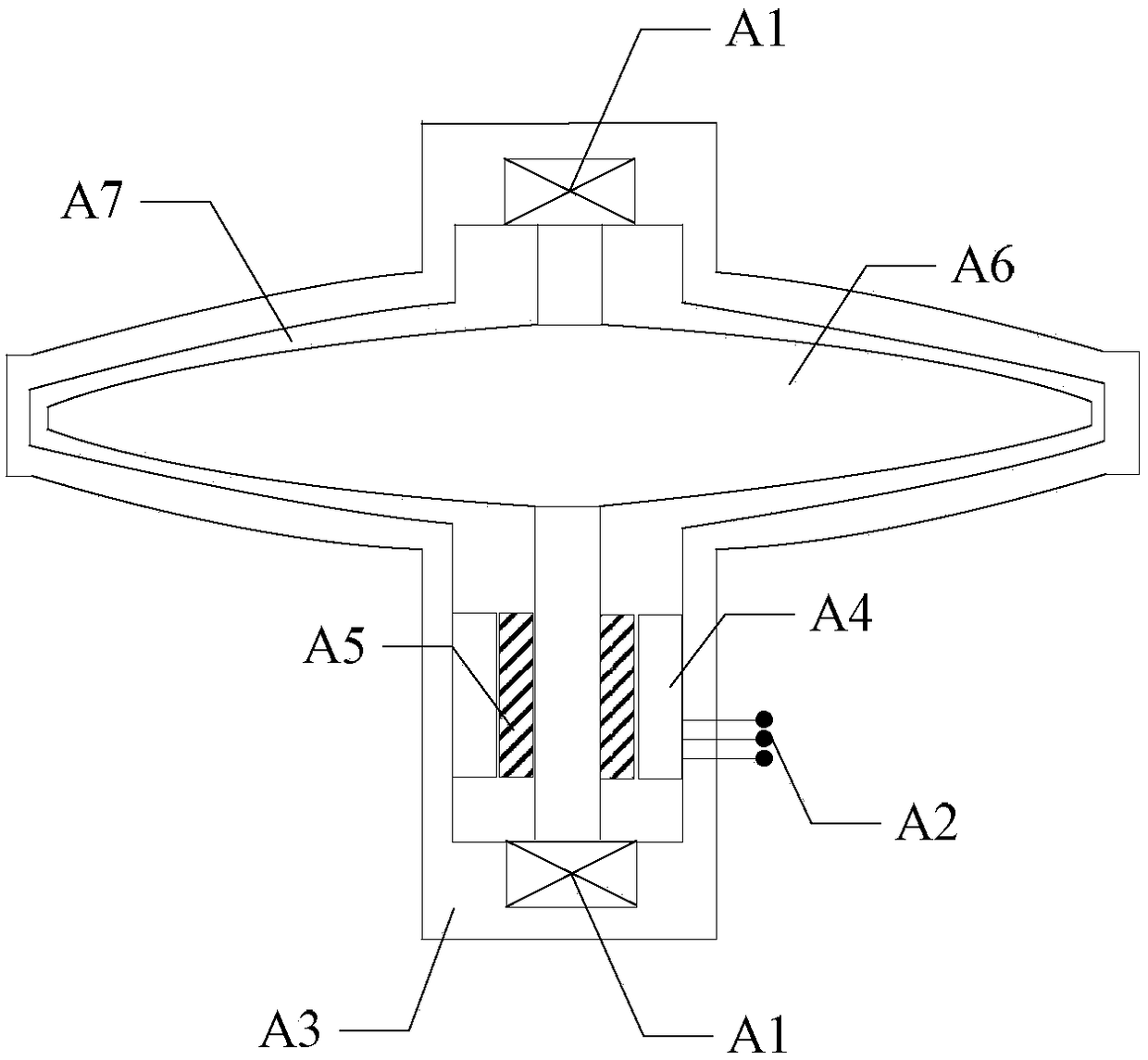

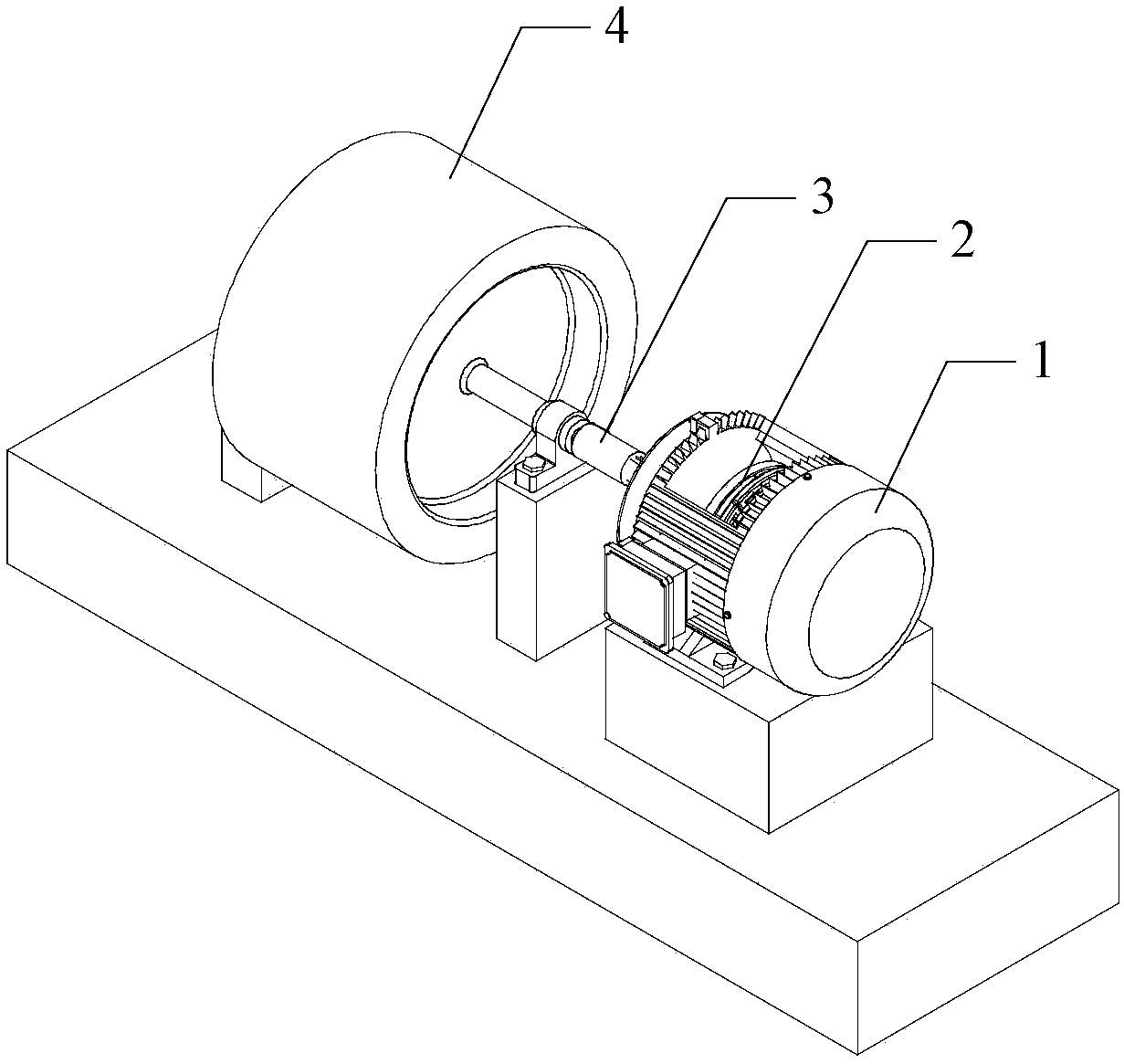

[0037] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, the first flywheel energy storage system described in this embodiment includes an input inverter, an output rectifier, an axial magnetic field multiple stator permanent magnet synchronous motor 2 and an inertial flywheel 4;

[0038] In the motoring state, the axial magnetic field multi-stator permanent magnet synchronous motor 2 inputs electric energy through the input inverter, and converts the electric energy into mechanical energy of the inertial flywheel 4;

[0039] In the power generation state, the inertia flywheel 4 provides mechanical energy to the axial magnetic field multiple stator permanent magnet synchronous motor 2, and outputs electric energy through the output rectifier;

[0040] The inertial flywheel 4 rotates synchronously with the rotor of the axial magnetic field multiple stator permanent magnet synchronous motor;

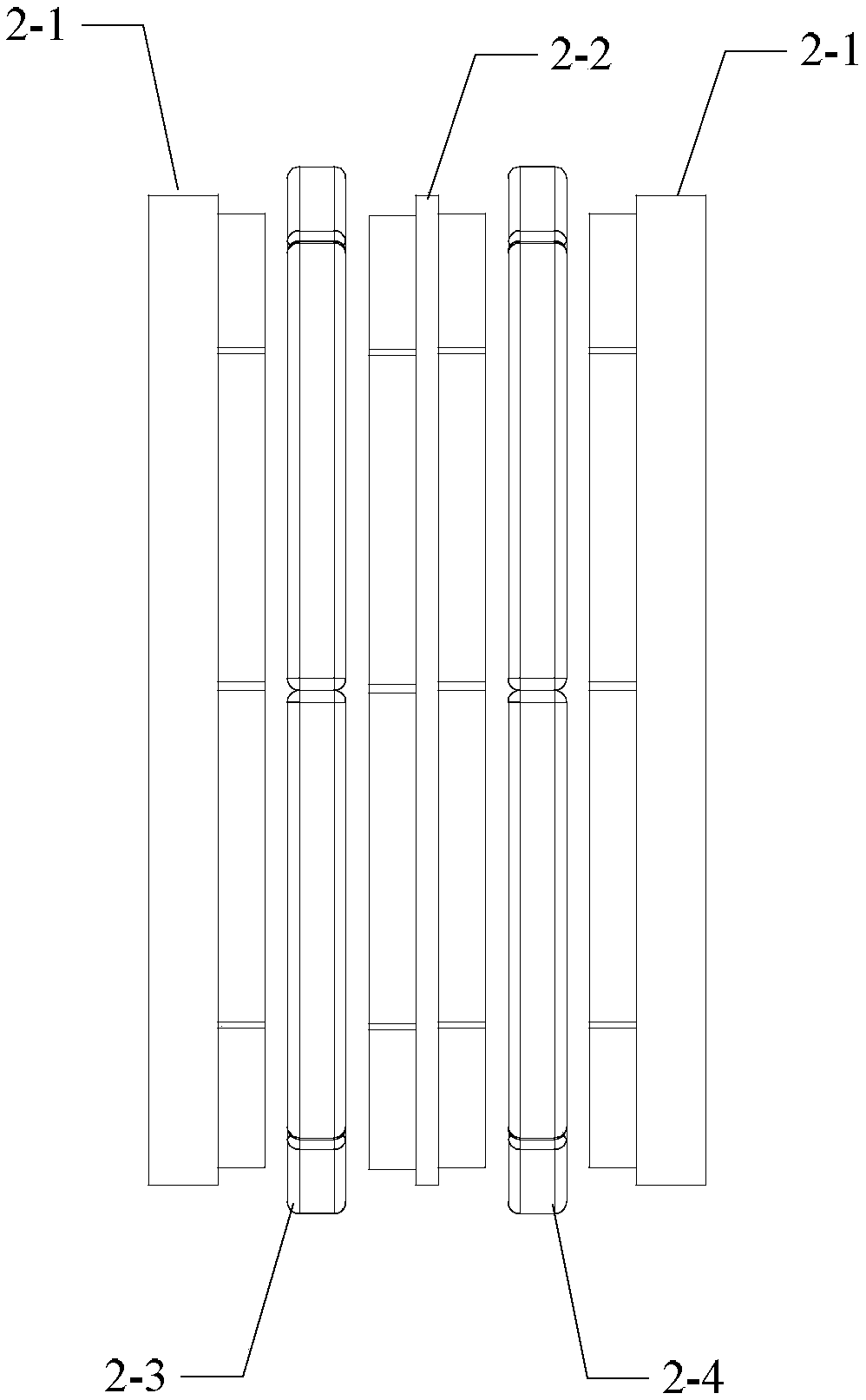

[0041] The axial magnetic field multiple stat...

specific Embodiment approach 2

[0058] Embodiment 2: The second flywheel energy storage system described in this embodiment includes an input inverter, an input motor, an output rectifier, an output generator, and an inertial flywheel 4;

[0059] The output terminal of the input inverter is connected to the lead wire of the stator winding of the input motor, and the input end of the output rectifier is connected to the lead wire of the stator winding of the output generator;

[0060] The output generator has j sets of stator windings, j is a natural number greater than or equal to 1;

[0061] The phase number of the output motor winding is greater than or equal to the phase number of the input motor winding;

[0062] The input motor is coaxially connected with the output generator;

[0063] The inertia flywheel 4 is sleeved on the outer circumference of the output generator or the inertia flywheel 4 is coaxially connected with the rotor of the output generator.

[0064] In this embodiment, the output recti...

specific Embodiment approach 3

[0065] Embodiment 3: The third flywheel energy storage system described in this embodiment includes an input inverter, a permanent magnet synchronous motor, 1+j output rectifiers and an inertial flywheel 4;

[0066] There are 1+j sets of AC windings with the same number of phases on the stator of the permanent magnet synchronous motor. After the corresponding phases of the remaining j sets of windings are connected in series, the tail end is connected to the head end of the corresponding phase of the first set of windings, and the 1+j output rectifiers are respectively connected to the lead-out lines of each series connection point and the head end of the last set of windings lead-out line connected;

[0067] The inertia flywheel 4 is sleeved on the outer circumference of the permanent magnet synchronous motor or the inertia flywheel 4 is coaxially connected with the rotor of the permanent magnet synchronous motor.

[0068] In this embodiment, the output rectifier is an uncon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com