Modulation ring of modulated permanent magnet gear and manufacturing method thereof

A technology for modulating rings and gears, which is applied to permanent magnet clutches/brakes, manufacturing motor generators, electric brakes/clutches, etc. It can solve the problems affecting the rigidity and reliability of the overall structure, and the complexity of the manufacturing process of the modulating rings. Compact and ingenious, high-fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

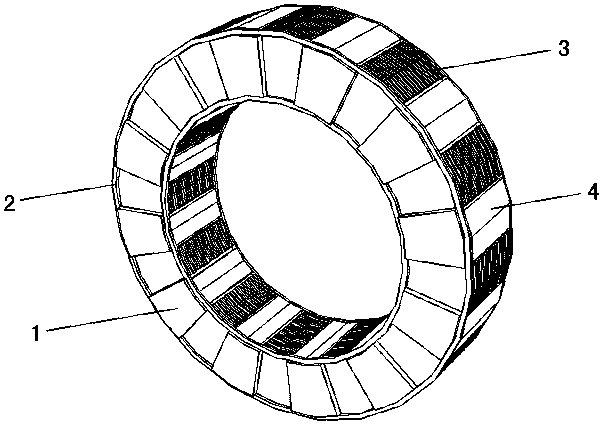

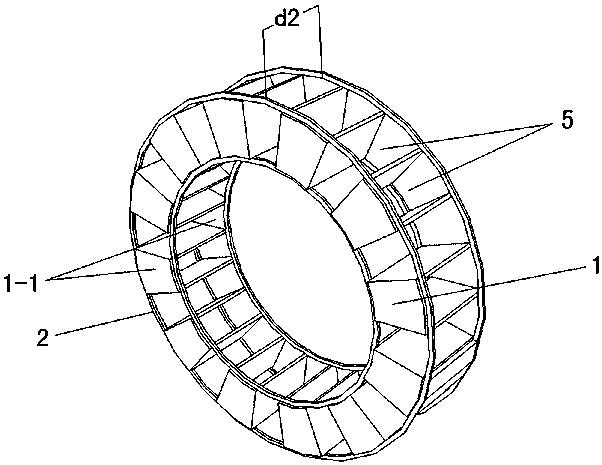

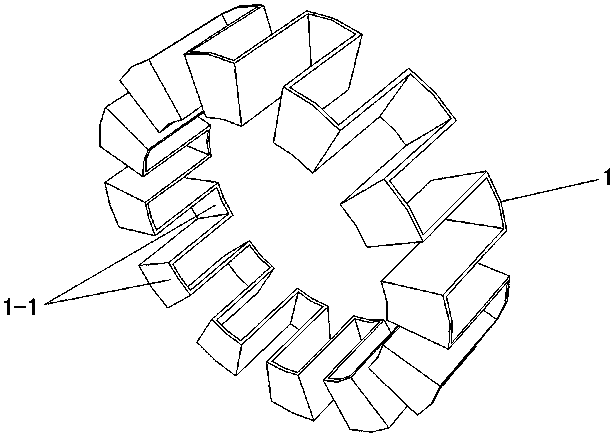

[0019] Specific implementation mode one: as Figure 1~Figure 6 As shown, the present invention discloses a modulating ring of a modulated permanent magnet gear, which includes a main body component 1, two end rings 2, a plurality of magnetically permeable components 3 and a plurality of non-magnetically permeable components 4, the main component 1 It is a cylindrical member formed by multiple alternate folds on both sides of the annular plate. The open end of each fold communicates with the corresponding end surface of the main body member 1 to form a ∏-shaped fold body 1-1. A plurality of the above-mentioned ∏-shaped folds 1-1 are equiangularly staggered along the circumferential direction of the main body member 1, and the opening directions of every two adjacent ∏-shaped folds 1-1 are opposite, and the middle positions of the two end rings 2 are equiangular along the circumferential direction respectively. A plurality of openings 2-4 are provided, and the plurality of openi...

specific Embodiment approach 2

[0020] Specific implementation mode two: as figure 2 , 4 As shown, this embodiment is a further description of Embodiment 1. Each of the end rings 2 includes an outer ring 2-1, an inner ring 2-2 and a plurality of fan-shaped separators 2-3. The outer ring 2-1 and the inner ring 2-2 are coaxially arranged, and the plurality of fan-shaped separators 2-3 are equally spaced around in a ring shape and arranged between the outer ring 2-1 and the inner ring 2-2 In between, the outer ring 2-1 and the inner ring 2-2 are welded and fixed by a plurality of fan-shaped separators 2-3, and the communication opening 2-4 is formed between every two adjacent fan-shaped separators 2-3.

specific Embodiment approach 3

[0021] Specific implementation mode three: as figure 1 , 5 As shown, this embodiment is a further description of Embodiment 1 or Embodiment 2. Each of the magnetic permeable members 3 is formed by stacking a plurality of silicon steel sheets 3 - 1 along the axial direction of the main body member 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com