Photovoltaic module intelligent inspection method applied to photovoltaic power generation system

A photovoltaic power generation system and photovoltaic module technology, applied in photovoltaic system monitoring, photovoltaic power generation, reasoning methods and other directions, can solve the problems of MPPT point offset, low inspection efficiency, high use cost, short time to work, measurement Intuitive, convenient and responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention will be described in detail below. This embodiment is developed on the basis of the technical solution of the present invention, and detailed implementation manners and specific operation processes are given.

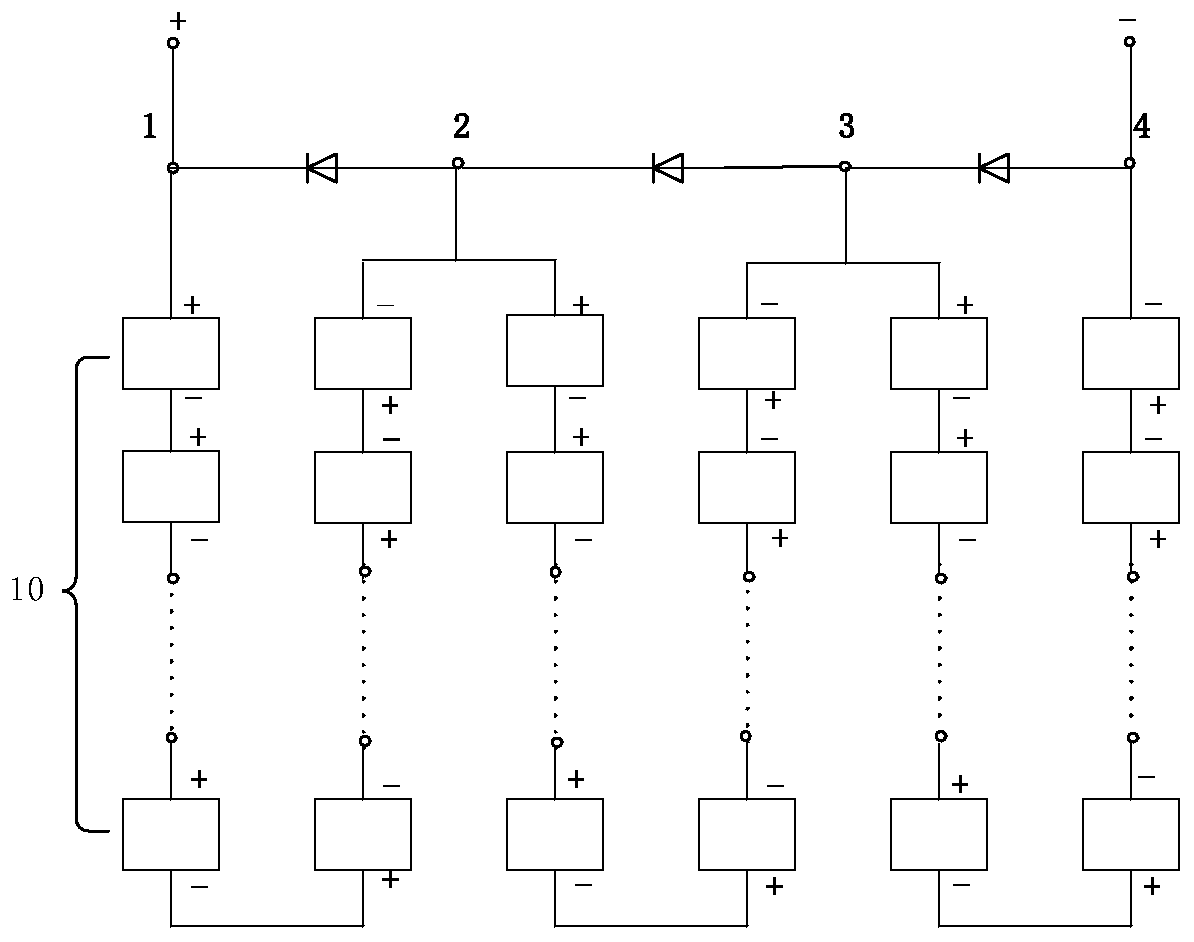

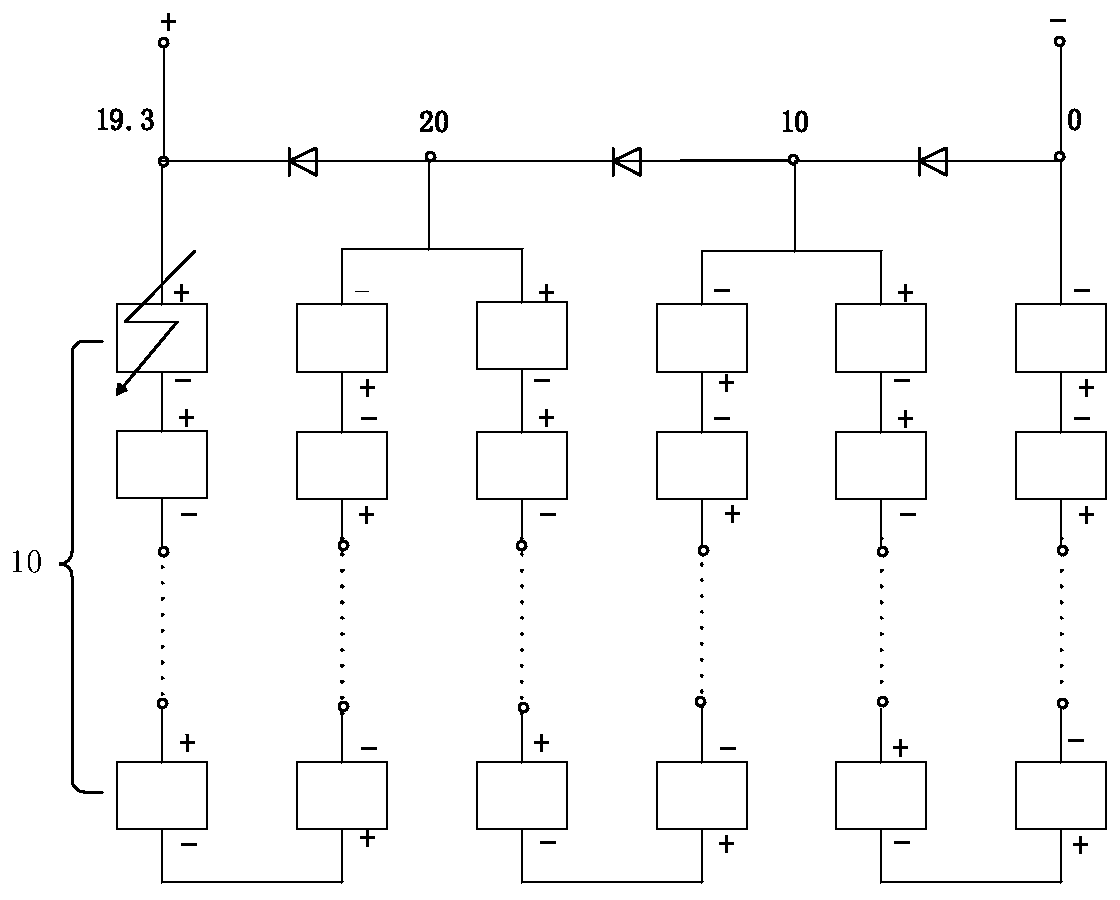

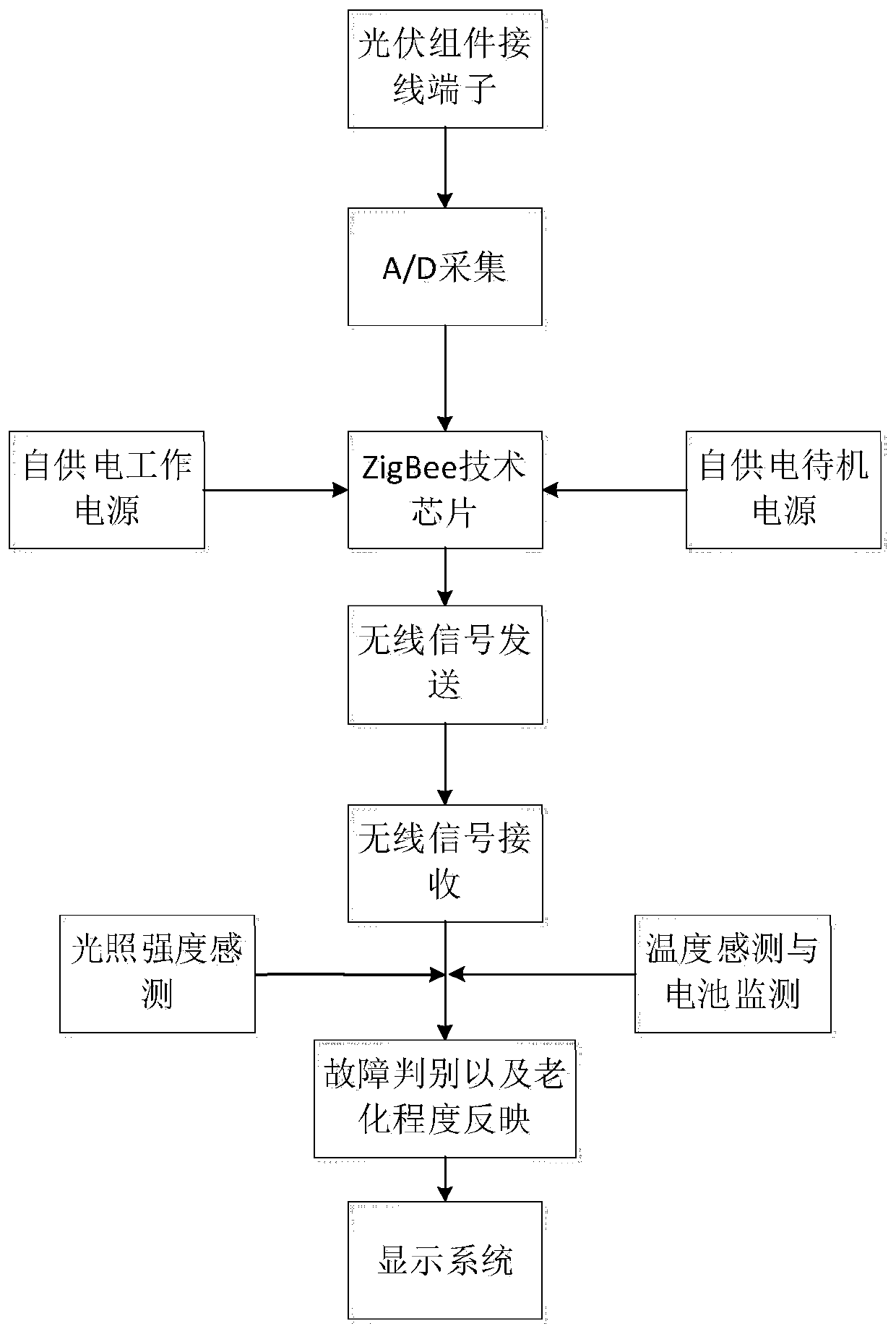

[0048] figure 1 It is a schematic diagram of the principle of the photovoltaic module intelligent inspection system of the present invention. The rated power is 250W, a total of 60 pieces, each column contains 10 pieces, and each 20 pieces form a series connection, and then 4 terminals are led out, and every two terminals are indirectly reversed. diode. Under normal circumstances, the voltage of the photovoltaic panel is 30V, that is, the potentials of points 1-4 are 30V, 20V, 10V, and 0V respectively; when a slice fails, the string where the slice is located is disconnected, and connect the two terminals of the string The reverse diode is turned on, and the voltage between the terminals changes from 10V to negative voltage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com