Wood floor paint spraying device

A technology for spray painting equipment and wooden floors, which is applied in spray booths, spray devices, liquid spray devices, etc., can solve the problems of operator harm, no drying design, low spray efficiency, etc., and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

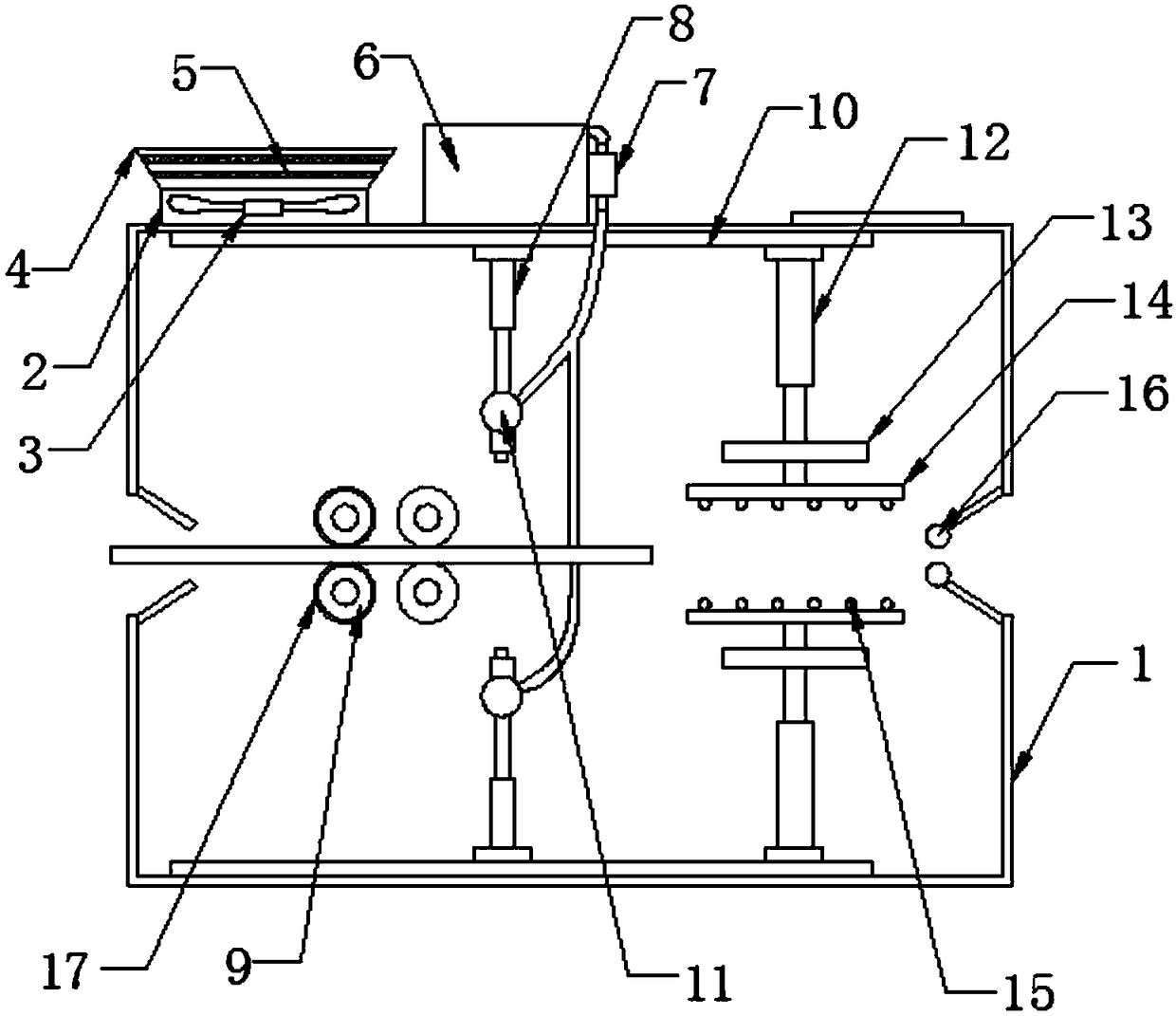

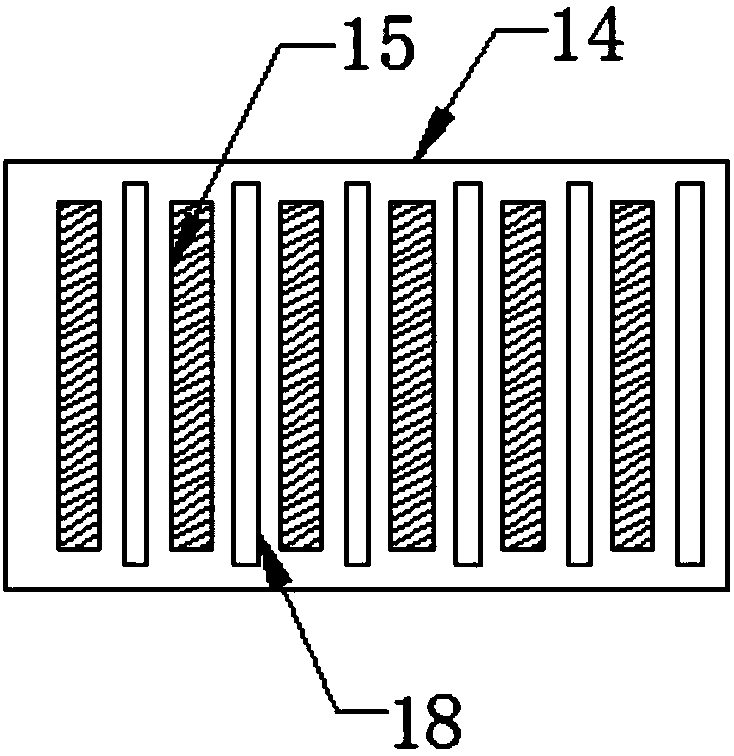

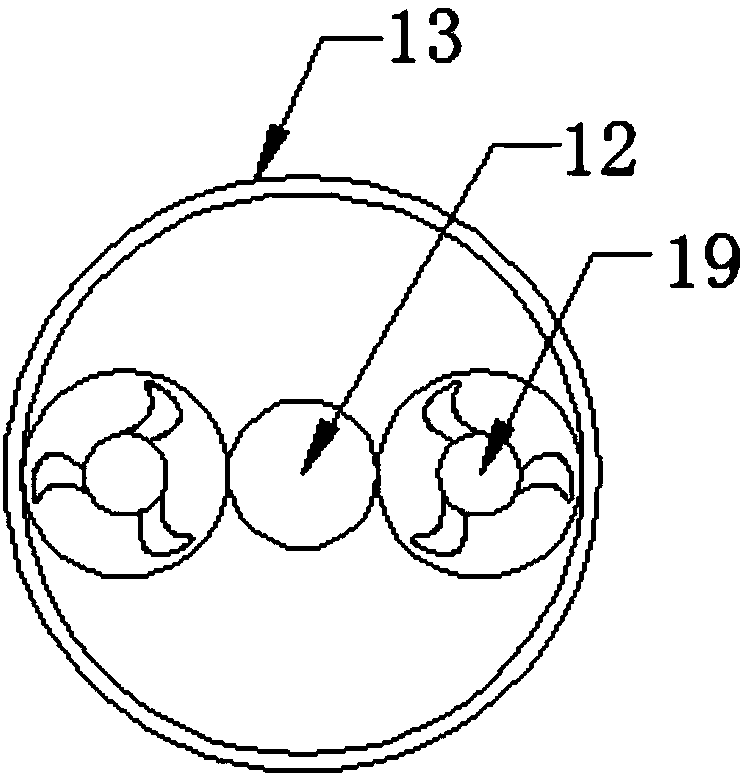

[0019] Such as Figure 1-5 As shown, a wood floor painting equipment includes a box body 1, a first feeding roller 9 and a drying plate 14. The top and bottom ends of the box body 1 are both fixed with a slide rail 10, and one end of the slide rail 10 is slidably connected There is a first electric telescopic rod 8, the output end of the first electric telescopic rod 8 is fixed with a paint tube 11, the bottom end of the paint tube 11 is evenly provided with a number of spray heads 22, the outside of the spray head 22 is provided with a protective tube 20, the protective tube The top end of the 20 is fixedly connected to the bottom end of the paint tube 11, the heating wire 21 is embedded in the inside of the protective cylinder 20, the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com