Large-stroke press-in mechanism for micro-nano carving

A technology with a large stroke and amplifying mechanism, applied in the field of probe-based micro-nano scribing, which can solve the problems of limited processing speed, poor dynamic performance of the press-in mechanism, and low stiffness of the cantilever beam, so as to enhance stability and compensate for coupling errors. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

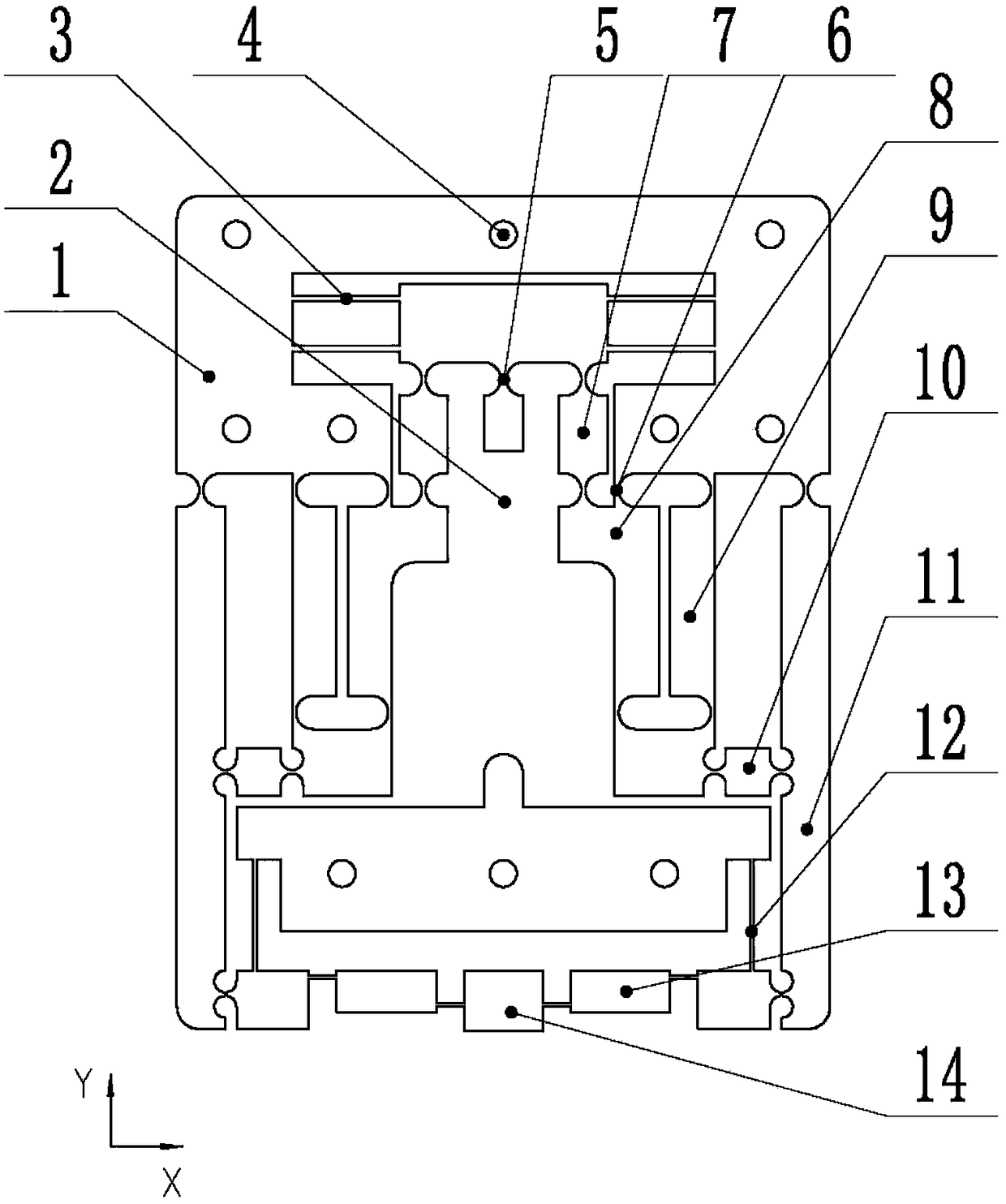

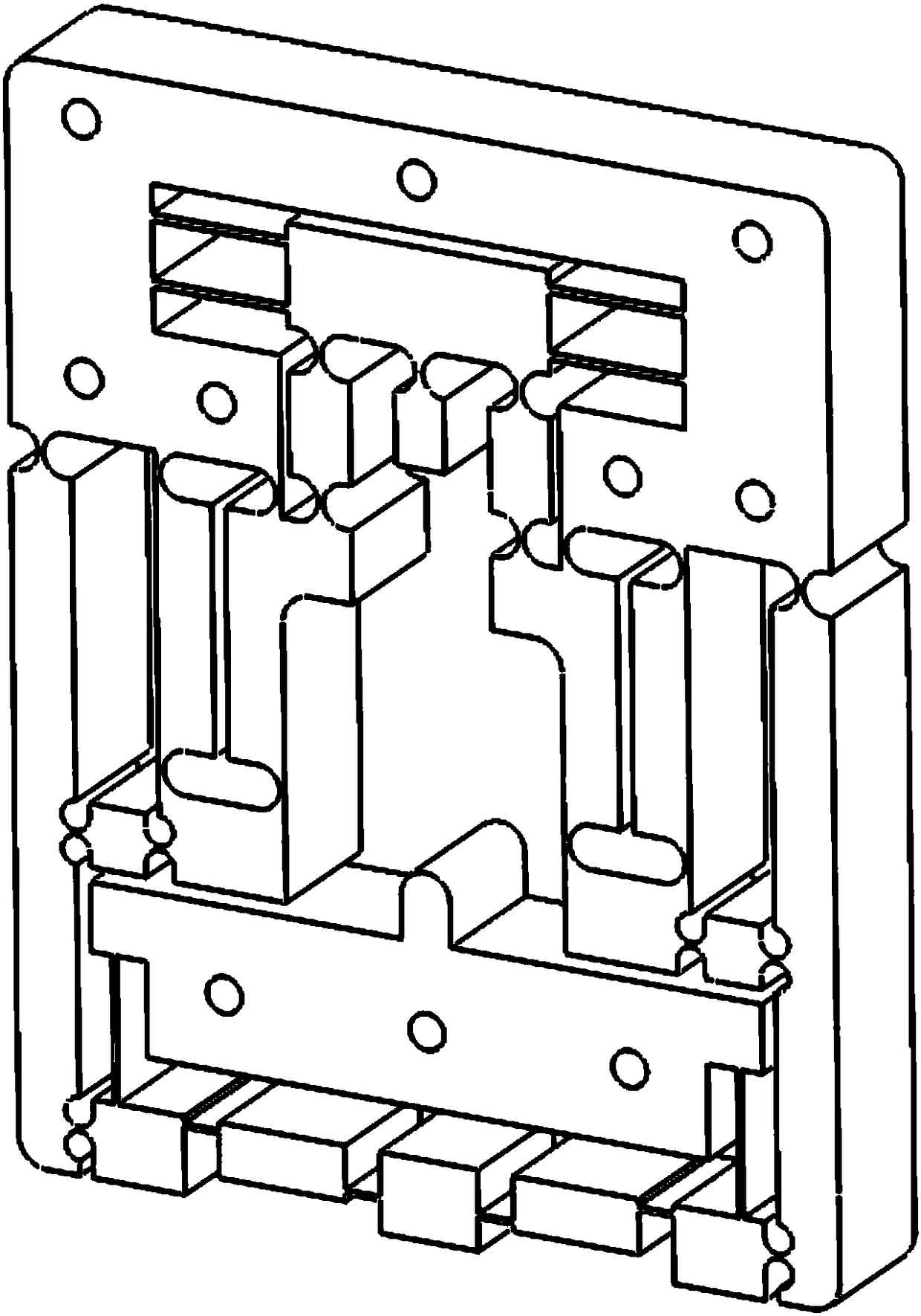

[0018] see Figure 1 ~ Figure 2 , which is a high-precision, high-stability large-stroke press-in mechanism for micro-nano scribing in this embodiment. 5 is connected with the double parallel plate guide mechanism 3, the double parallel plate guide mechanism 3 is connected with the lever amplification mechanism I8 through the connecting rod I7, and then connected with the parallelogram guide mechanism 9 through the semi-notch type flexible hinge 6, wherein the parallelogram guide mechanism 9 Share a rod with the lever amplification mechanism I 8, the parallelogram guide mechanism 9 is connected with the lever amplification mechanism II 11 through the connecting rod II 10, and directly connected with the bridge type amplification mechanism 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com