Double-cutting type one-time forming manufacturing device for bamboosplit steaming basket

A double-cutting, steamer technology, applied in mechanical equipment, manufacturing tools, steam cooking utensils, etc., can solve the problems that affect the use method and effect of the steamer stacked Arhat, can not meet the requirements of large-scale, fast production, and poor matching size consistency, etc. Achieve the effect of good product structure and size consistency, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

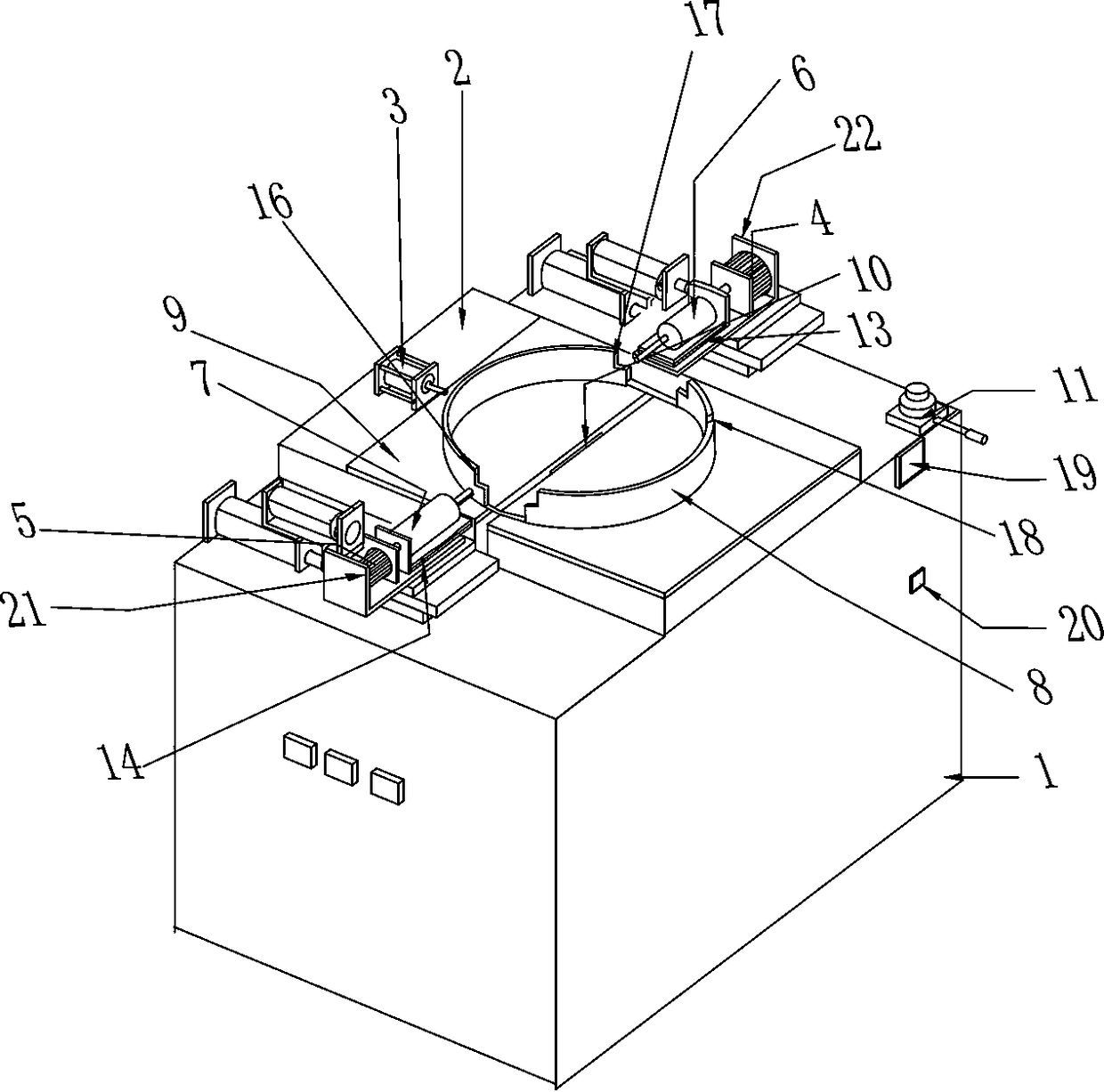

[0015] Base 1 is 1310mm long, 660mm wide and 640mm high with four legs; base platform 2 is 1310mm long, 940mm wide, and 40mm thick; stroke cylinder 3 is SC100*100, and cylinders 4 and 5 are SDA40*50-B, trimmed The models of machine 6 and 7 are 200mm*70mm in length (diameter); the inner diameter of the restricting ring 8 is 515mm, the height is 100mm, the material is ordinary steel, and the thickness is 20mm; the semicircular plate 9 is an ordinary steel plate with an outer diameter of 553mm and a thickness of 10mm; 1. Two-dimensional adjustment platforms 10, 13, and 14 are 300mm long, the base width of the visible dovetail groove surface is 160mm, the height is 20mm, the base surface width of the dovetail inner corner is 40mm, the top surface width of the dovetail groove is 132mm, and the height of the dovetail groove is 21mm; Adjusting screw rods in the two-dimensional adjustment platforms 13 and 14 are M20 screw rods; the air source switch 11 model is 4R210-08, which is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com