A method for enhancing the strength of two-layer leather by means of filling

A technology of leather and means, which is applied in the field of enhancing the strength of two-layer leather by means of filling, which can solve the problems of reducing product quality and use comfort, reducing the hygienic performance of two-layer leather, and unable to solve the use value, etc., to achieve good product stability, Good filling effect and improvement of filling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

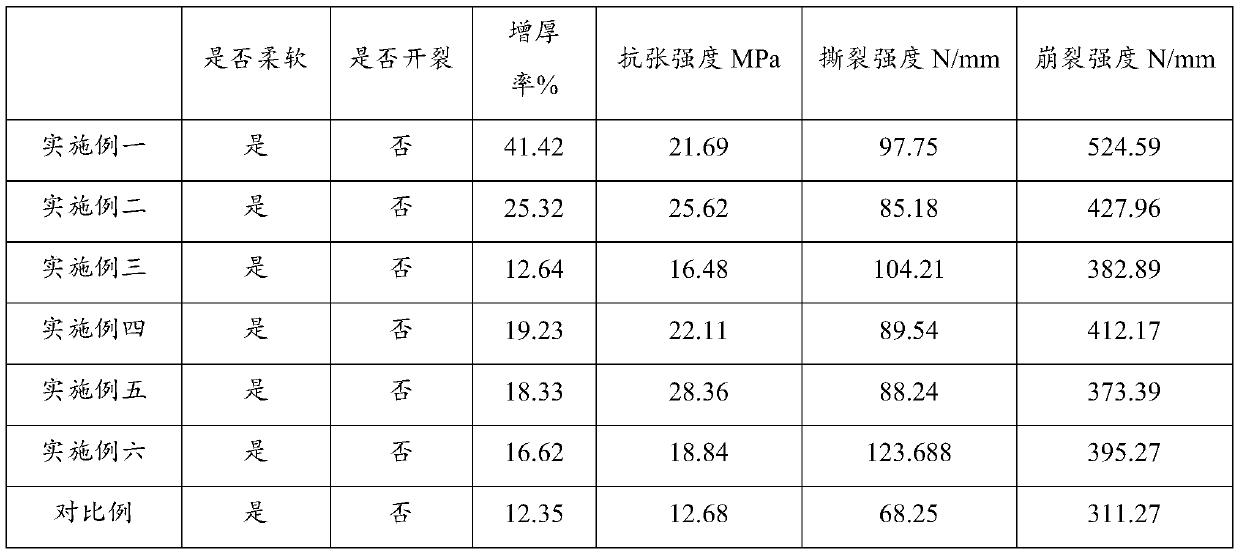

Examples

Embodiment 1

[0023] Two-layer tanned leather filling reinforcement process is as follows:

[0024] Two-layer chrome tanned leather→squeezing→shaving→weighing→rewetting→washing→neutralization→filling→dyeing, fatliquoring→washing→drying→finishing→two-layer reinforced hide. The specific steps are:

[0025] (1) Select two-layer leather: select two-layer tanned leather through chrome tanning;

[0026] (2) Pre-filling treatment: the selected second-layer tanned leather is sequentially squeezed, shaved, weighed, re-wetted, washed, and neutralized. After neutralization, the pH of the second-layer leather is 4.5;

[0027] (3) Filling: Put the two-layer leather that has been treated before filling into the drum, and add water with a tare weight of 400%, adjust the temperature to 80°C, and then add 30% polyvinyl alcohol (the degree of polymerization is 1700, Alcoholysis degree is 70%), rotate 8h;

[0028] (4) Post-filling treatment: the filled two-layer leather is sequentially dyed, fatliquored, w...

Embodiment 2

[0030] Two-layer tanned leather filling reinforcement process is as follows:

[0031] Second-layer aldehyde tanned leather→squeezing→shaving→weighing→rewetting→washing→neutralization→filling→dyeing, fatliquoring→washing→drying→finishing→two-layer reinforced hide. The specific steps are:

[0032] (1) Select two-layer leather: select two-layer tanned leather through aldehyde tanning agent tanning;

[0033] (2) Pre-filling treatment: the selected second-layer tanned leather is squeezed, smoothed, weighed, re-wetted, washed, and neutralized in sequence. After neutralization, the pH of the second-layer leather is 9.0;

[0034] (3) Filling: Dissolve polyvinyl alcohol with a tare weight of 5% (the degree of polymerization is 300, and the degree of alcoholysis is 90%) in water with a tare weight of 100%, and the temperature is adjusted to 75°C. In the drum of the two-layer leather, rotate for 4 hours;

[0035] (4) Post-filling treatment: After the filled two-layer leather is sequen...

Embodiment 3

[0037] Two-layer tanned leather filling reinforcement process is as follows:

[0038] Two-layer zirconium tanned leather→squeezing→shaving→weighing→rewetting→washing→neutralization→filling→dyeing, fatliquoring→washing→drying→finishing→two-layer reinforced hide. The specific steps are:

[0039] (1) Select two-layer leather: select two-layer tanned leather tanned by zirconium tanning agent;

[0040] (2) Pre-filling treatment: the selected second-layer tanned leather is sequentially squeezed, shaved, weighed, re-wetted, washed, and neutralized. After neutralization, the pH of the second-layer leather is 6.0;

[0041] (3) Filling: Put the two-layer leather that has been treated before filling into the drum, and add water with a tare weight of 400%, adjust the temperature to 60°C, and then add 20% polyvinyl alcohol with a tare weight (the degree of polymerization is 1000, Alcoholysis degree is 75%), rotate 2h;

[0042] (4) Post-filling treatment: After the filled two-layer leath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com