Preparation method of nickel electrode

A nickel electrode and porous nickel technology, applied in the field of electrodes, can solve problems such as deterioration of filling uniformity, failure to fill, gelation of slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a nickel electrode, prepared according to the following steps:

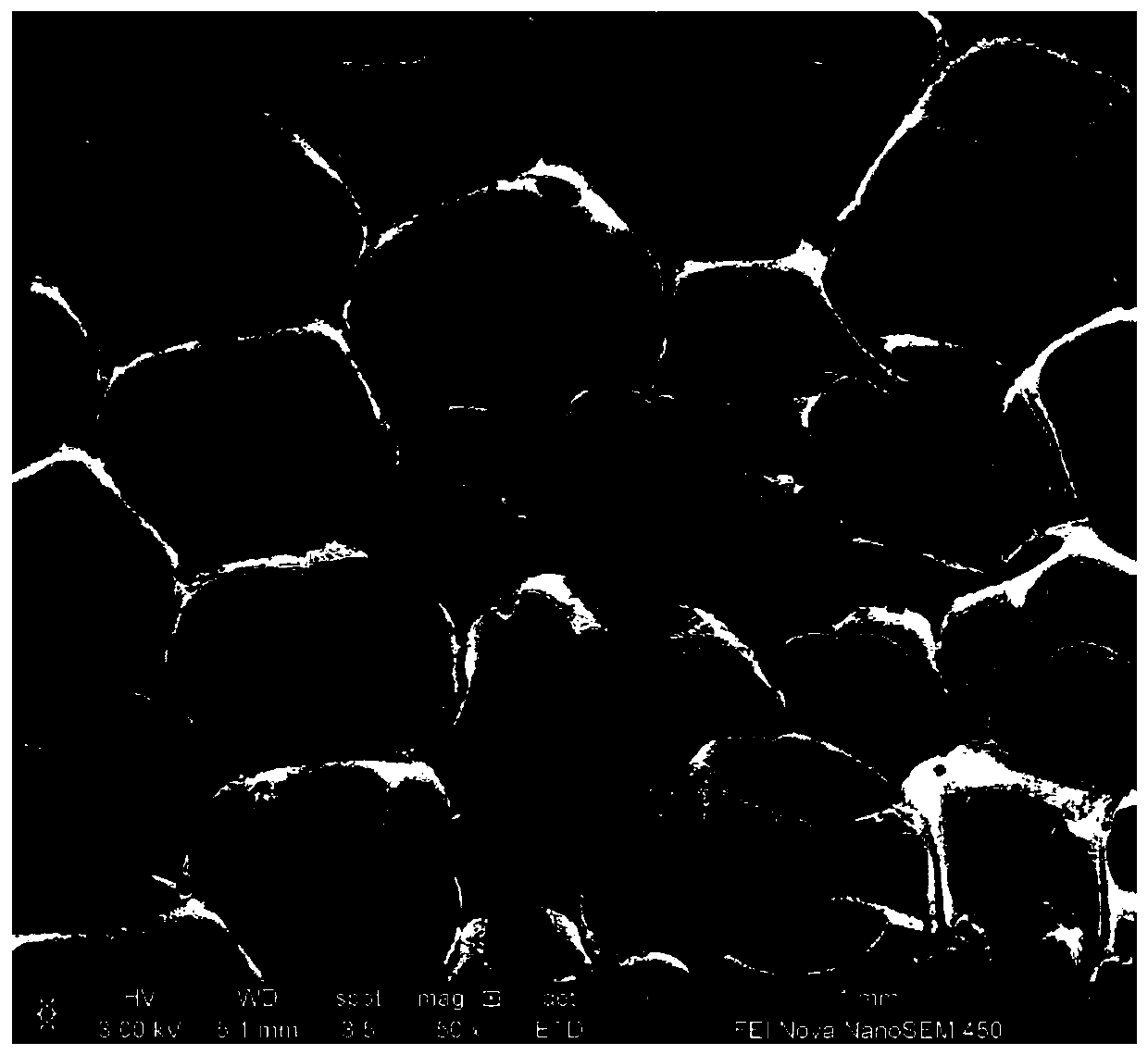

[0042] S1, take 103mm wide, longitudinal tensile strength T≥1.8N / mm, thickness D 0 =1.8±0.1mm foamed nickel is used as a porous nickel substrate, and the SEM image of its spatial cavity structure is as follows figure 1 shown, use a roller to roll it to D 1 =1.30±0.01mm;

[0043] S2. Use a conventional powder feeding machine to fill the active material (in this embodiment, β-type spherical nickel hydroxide is taken as an example), so that the average filling density of the active material in the porous nickel matrix is ρ 1 , where ρ 1 Close to the bulk density of the active substance itself, that is, the filling level of the general industry is 1.3-1.8g / mL;

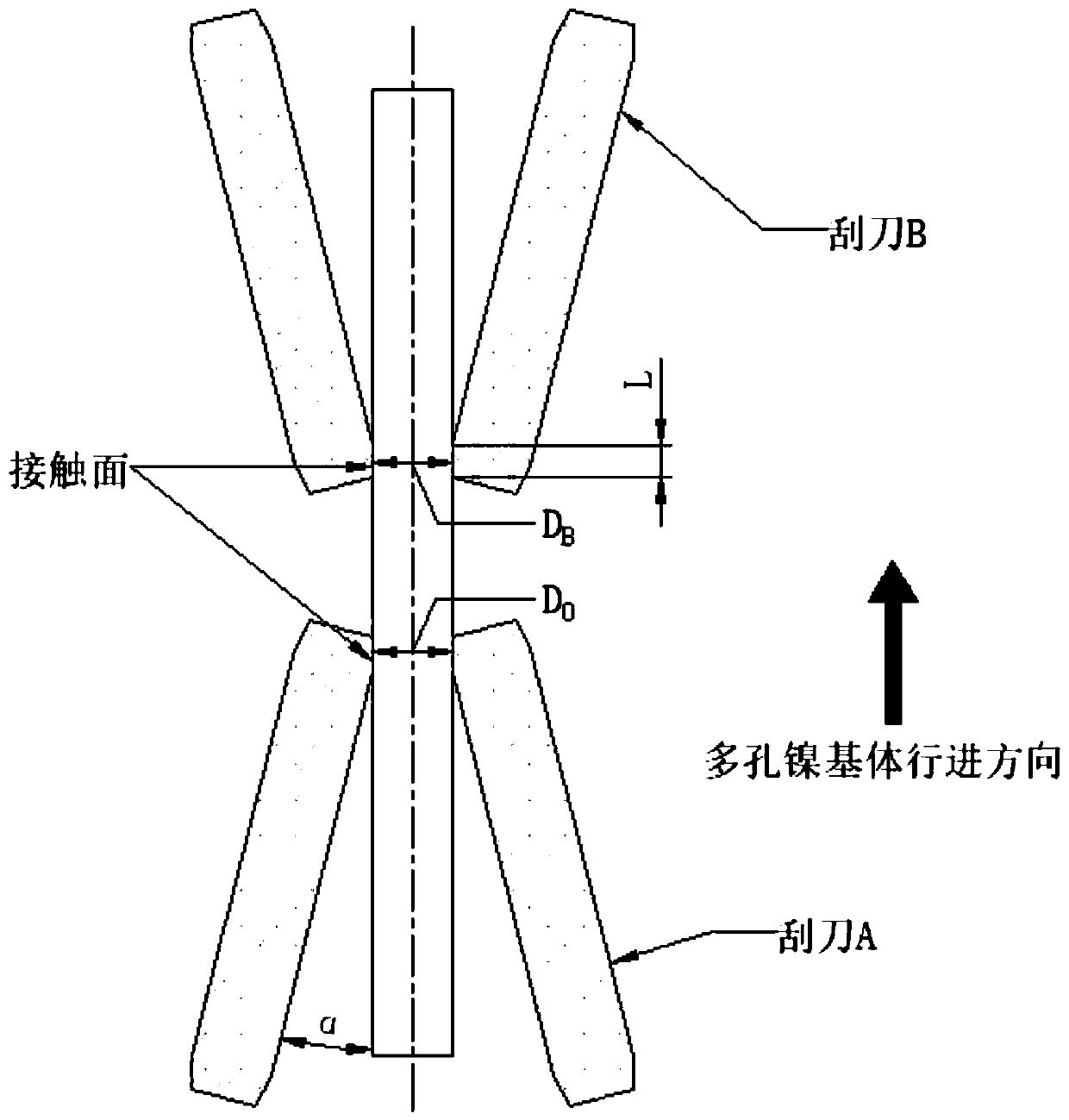

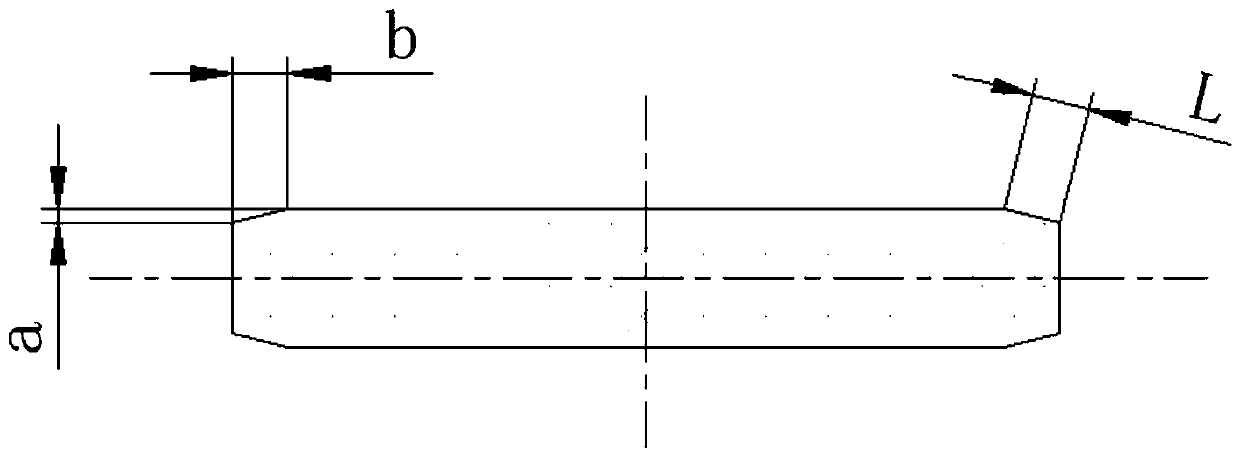

[0044] S3, see figure 2 , figure 2 It is a diagram for the use of scraper A and scraper B. The direction of the thick arrow represents the direction of travel of the porous nickel substrate. The direction of the edge ...

Embodiment 2

[0050] This embodiment provides a nickel electrode, the preparation steps of which are the same as those of Embodiment 1, except that the specific parameter values controlled in each step are different, specifically prepared according to the following steps:

[0051] S1, take 103mm wide, longitudinal tensile strength T≥1.8N / mm, thickness D 0 =1.8±0.1mm foamed nickel is used as a porous nickel substrate, and the SEM image of its spatial cavity structure is as follows figure 1 shown, use a roller to roll it to D 1 =1.30±0.01mm;

[0052] S2. Use a conventional powder feeding machine to fill the active material (in this embodiment, β-type spherical nickel hydroxide is taken as an example), so that the average filling density of the active material in the porous nickel matrix is ρ 1 , where ρ 1 Close to the bulk density of the active substance itself, that is, the filling level of the general industry is 1.3-1.8g / mL;

[0053] S3, see figure 2 , figure 2 It is a diagram ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com