A kind of asphalt concrete and preparation method thereof

A technology for asphalt concrete and rock asphalt, applied in the field of asphalt concrete and its preparation, can solve problems such as affecting the life and work of surrounding people, loud noise, etc., and achieve the effects of improving filling uniformity, reducing noise, and improving sound absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

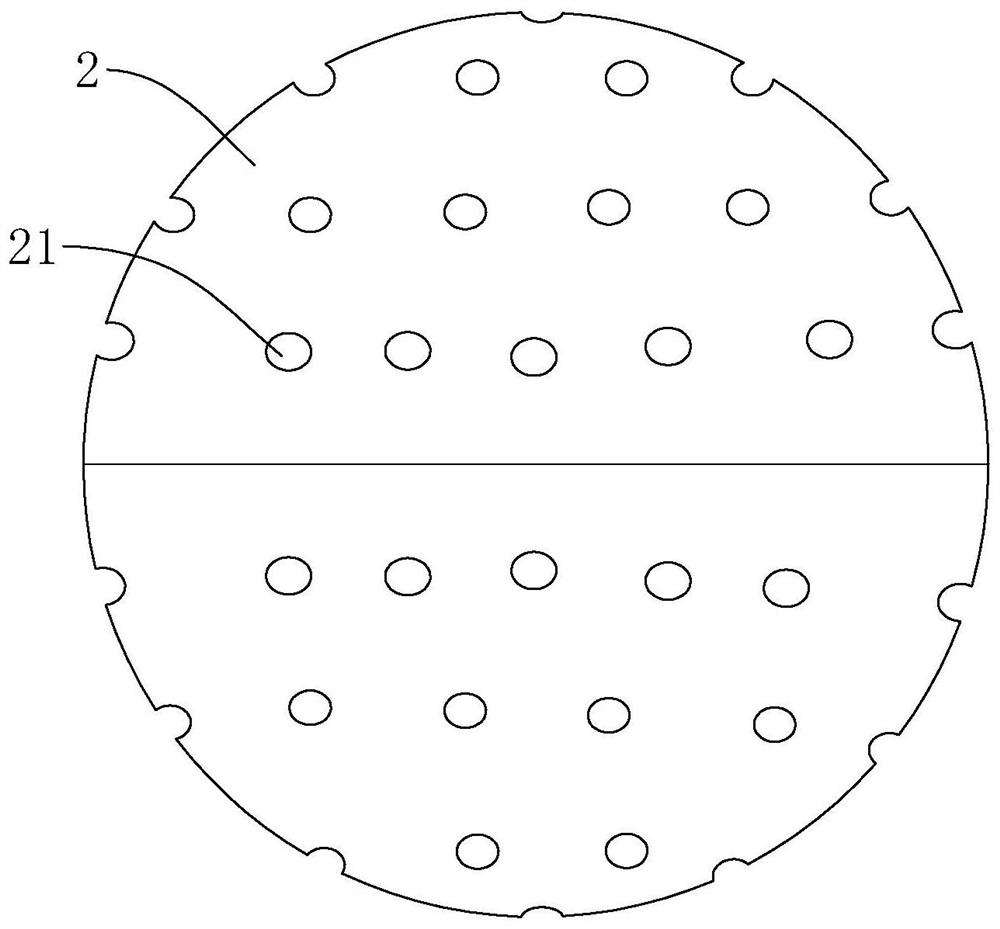

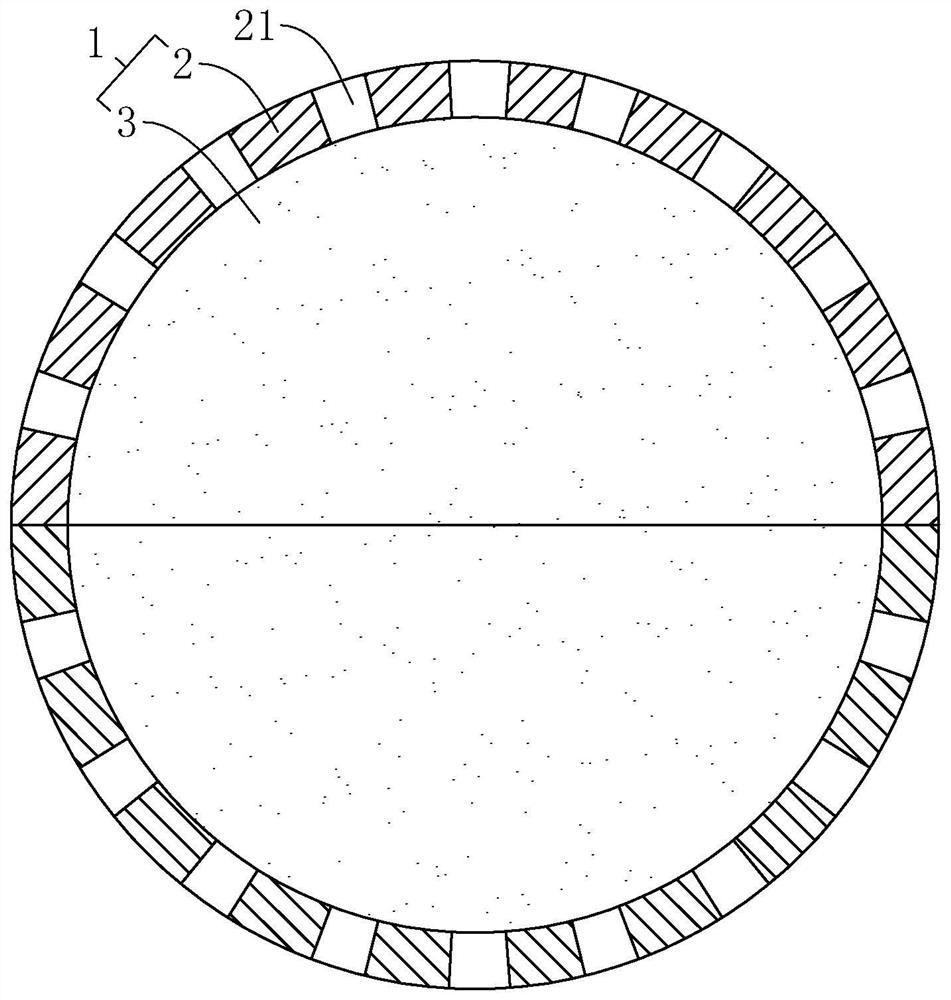

[0039] Embodiment 1: a kind of asphalt concrete, the components included and the corresponding parts by weight are shown in Table 1, and are prepared by the following steps:

[0040] S1, prepare rock asphalt modified asphalt of corresponding parts by weight and melt it, take noise reduction particles of corresponding parts by weight and immerse in molten rock asphalt modified asphalt, take out the noise reduction particles for later use; the outer surface of the noise reduction particles taken out The asphalt protective layer formed after drying rock asphalt modified asphalt.

[0041] S2, take the corresponding parts by weight of polyester fibers and granular lignin fibers and mix uniformly to form a fiber mixture; take the fiber mixture and corresponding parts by weight of mineral powder, quartz particles and crushed stones and add them to the molten rock asphalt modified asphalt , and mix uniformly to obtain the first mixture. Add the noise-reducing particles to the first m...

Embodiment 2-9

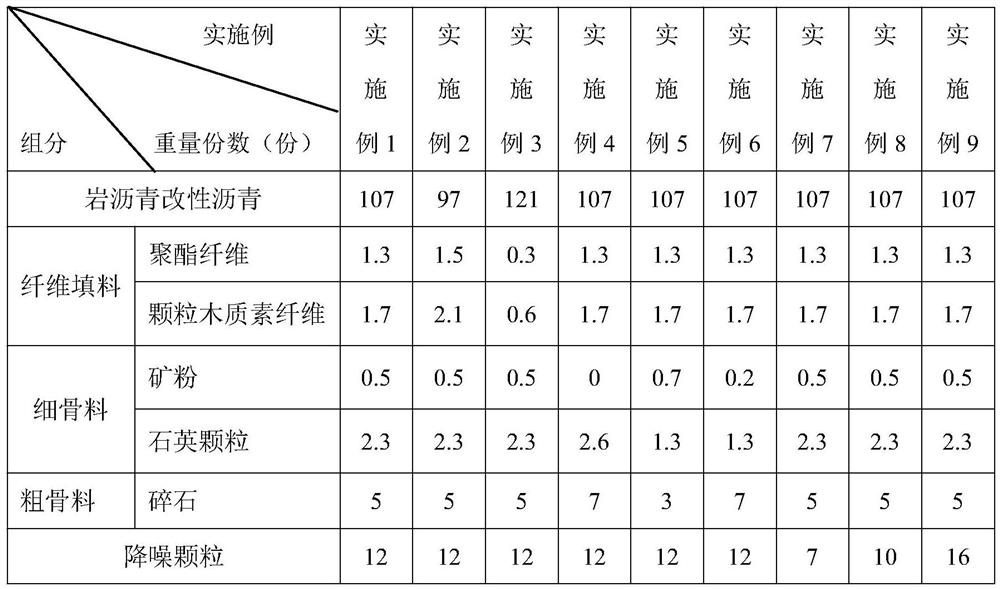

[0044] Example 2-9: an asphalt concrete, the only difference from Example 1 is that the parts by weight of some components are different, and the specific components and corresponding parts by weight are shown in Table 1.

[0045] Table 1. Components of Examples 1-9 and their corresponding parts by weight table

[0046]

Embodiment 10-11

[0047] Embodiments 10-11: an asphalt concrete, the only difference from Embodiment 1 is that the outer diameters of the noise-reducing particles are 15 mm and 25 mm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com