Pre-bending construction method for steel-concrete combined girders

A construction method and pre-bending technology, applied in bridges, bridge materials, bridge construction and other directions, can solve the problems of vehicle traffic interference, temporary lifting heavy, imposing heavy objects, etc., and achieve the effects of convenient construction, simple construction and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

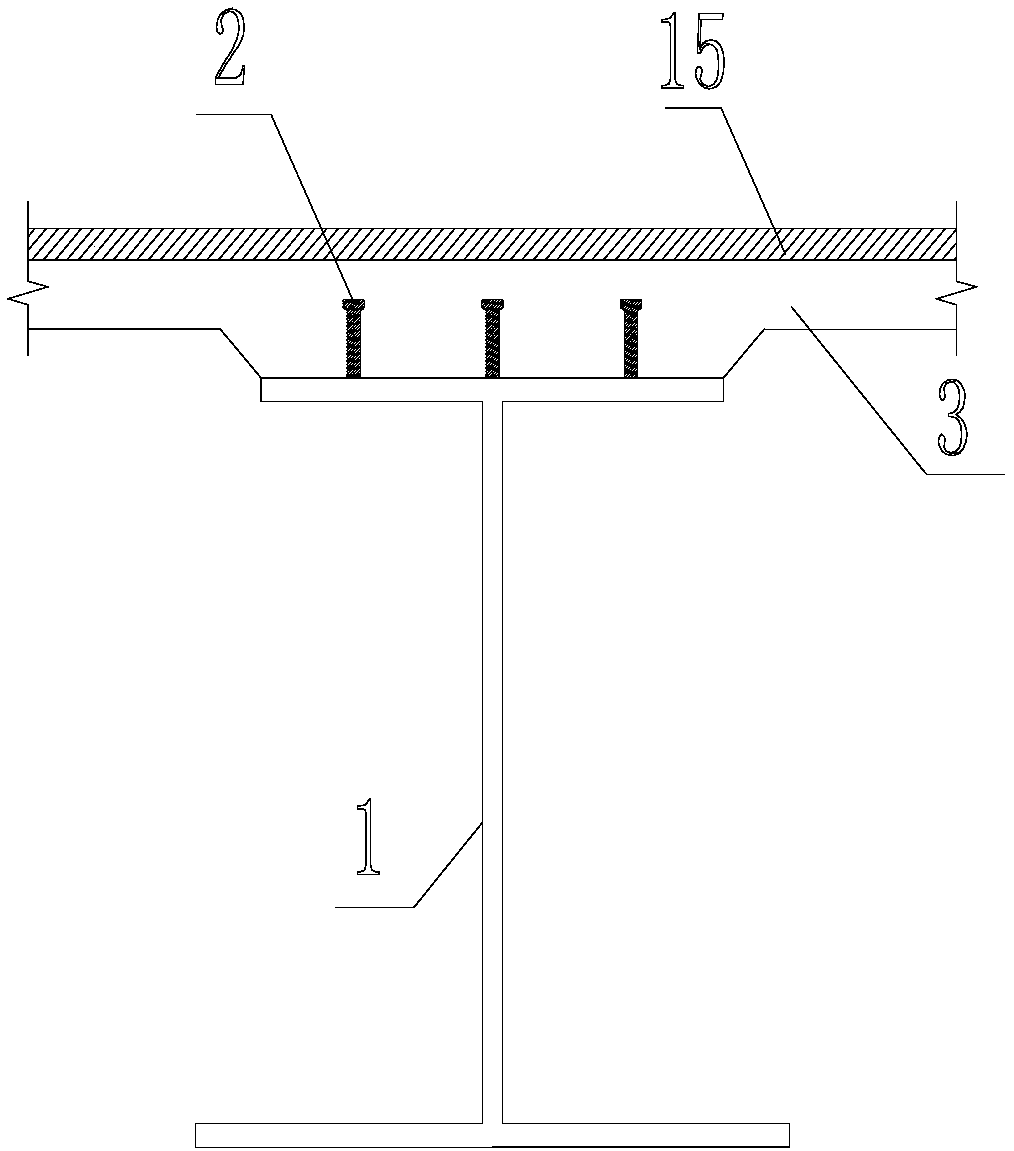

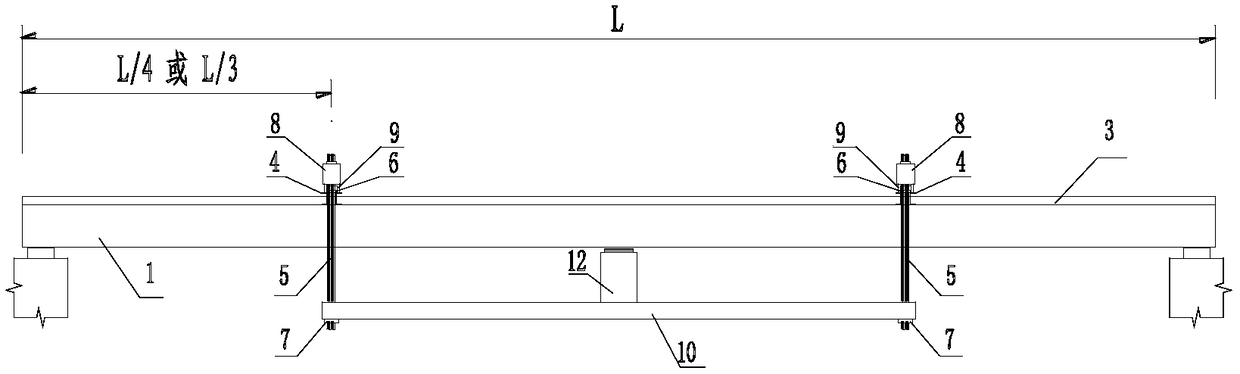

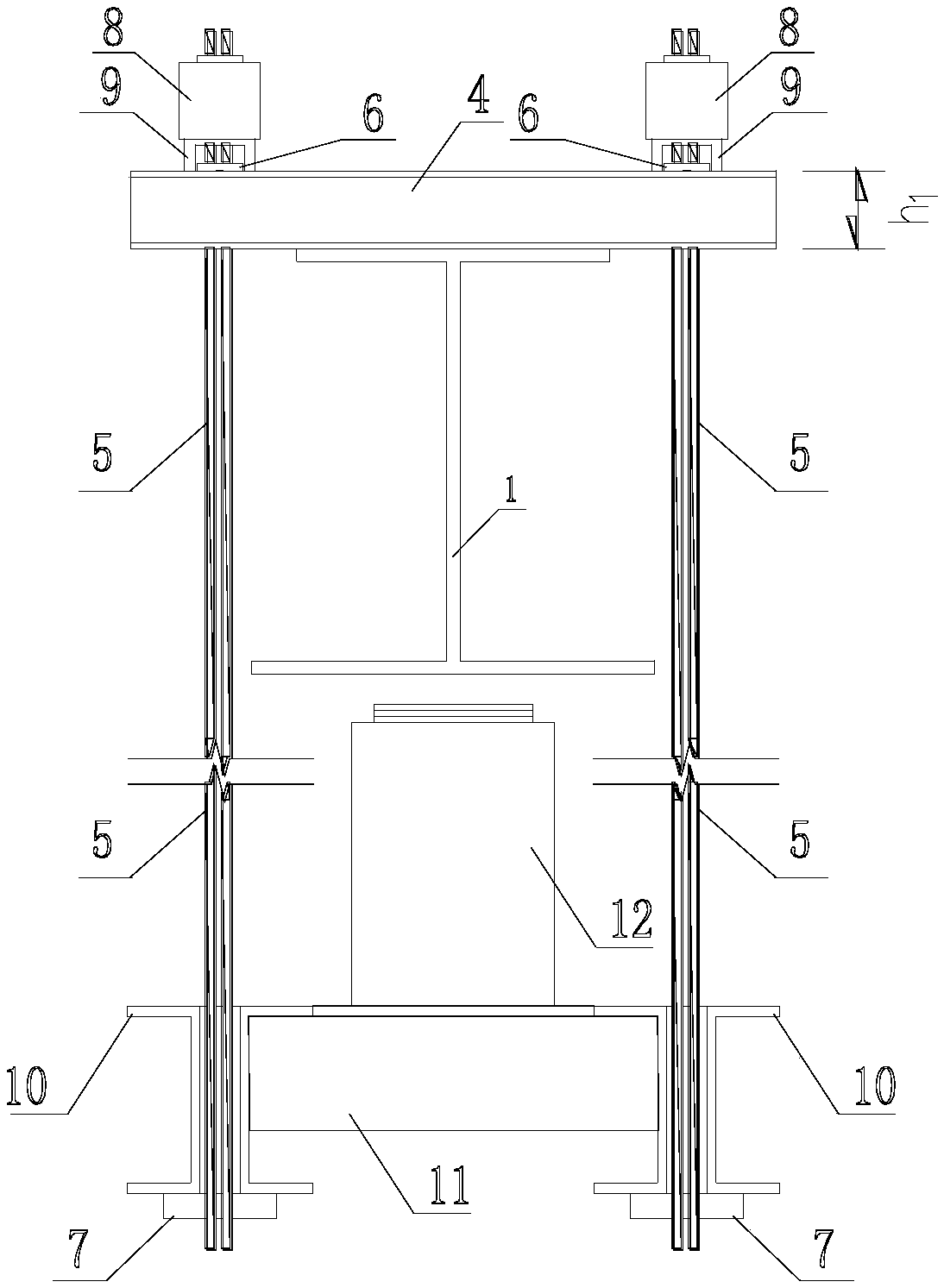

[0030] refer to Figure 1 to Figure 6 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each component of the present invention will be described in detail below.

[0031] The steel-concrete combined girder bridge structure includes a steel girder 1 , a concrete bridge deck 3 , a shear connector 2 and a bridge deck pavement 15 .

[0032] The present invention provides a steel-concrete combined girder bridge pre-bending structure, comprising a steel girder 1, a pre-bending beam 10 arranged below the steel girder 1 along the longitudinal direction of the bridge, and a pre-bending beam 10 arranged between the pre-bending beam 10 and the steel girder 1 The pre-bending support 12, between the pre-bending beam 10 and the steel beam 1 is provided with a pre-bending tension member 5 on both sides of the pre-bending support 12, the pre-bending tension member 5 and / or pre-bending The supporting member 12 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com