Waterproof automatic cable winding and unwinding device

A pay-off device and automatic technology, applied in the field of construction machinery, can solve the problems of time-consuming and laborious dragging of cables by manpower, inability to truly eliminate hidden dangers, and inability to synchronise dragging in time, so as to save manpower dragging, avoid major safety accidents, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

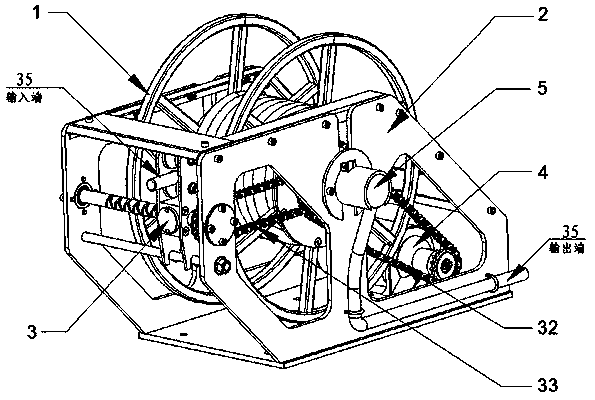

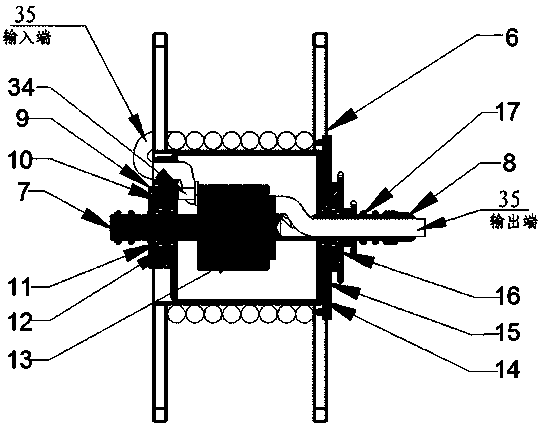

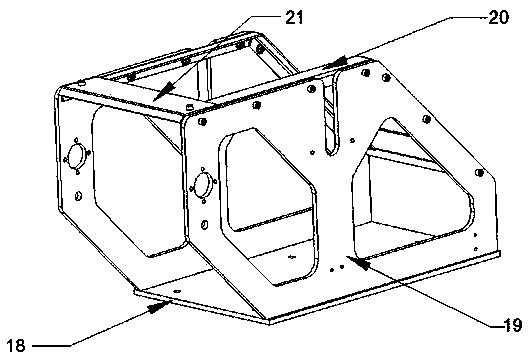

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention mainly includes a cable reel main body 1, a reel main body fixing frame 2, a cable guide assembly 3, a drive assembly 4, a cable sheath assembly 5, and a power supply cable 35.

[0019] The cable reel body 1 has a waterproof function, which can effectively prevent dust and water from entering, ensure its safety in use, and avoid electric leakage accidents. The reel frame 6 of the cable reel body 1 is fixed on both sides of the reel fixed shaft 7, and an outer sealing ring 14 and an outer sealing plate 15 are arranged between the reel frame 6 on one side and the reel fixed shaft 7. The outer side of the sealing plate 15 is equipped with a compound transmission sprocket 16, which is locked with a shaft lock nut 17, the cable waterproof joint 8 is installed outside the shaft lock nut 17, and the reel frame 6 on the other side is fixed to the reel An inner dustproof ring 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com