Smart pcb oven for remote monitoring

A remote monitoring, oven technology, applied in the direction of printed circuit stress/deformation reduction, printed circuit components, printed circuits, etc., to achieve the effect of recycling, improving baking efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

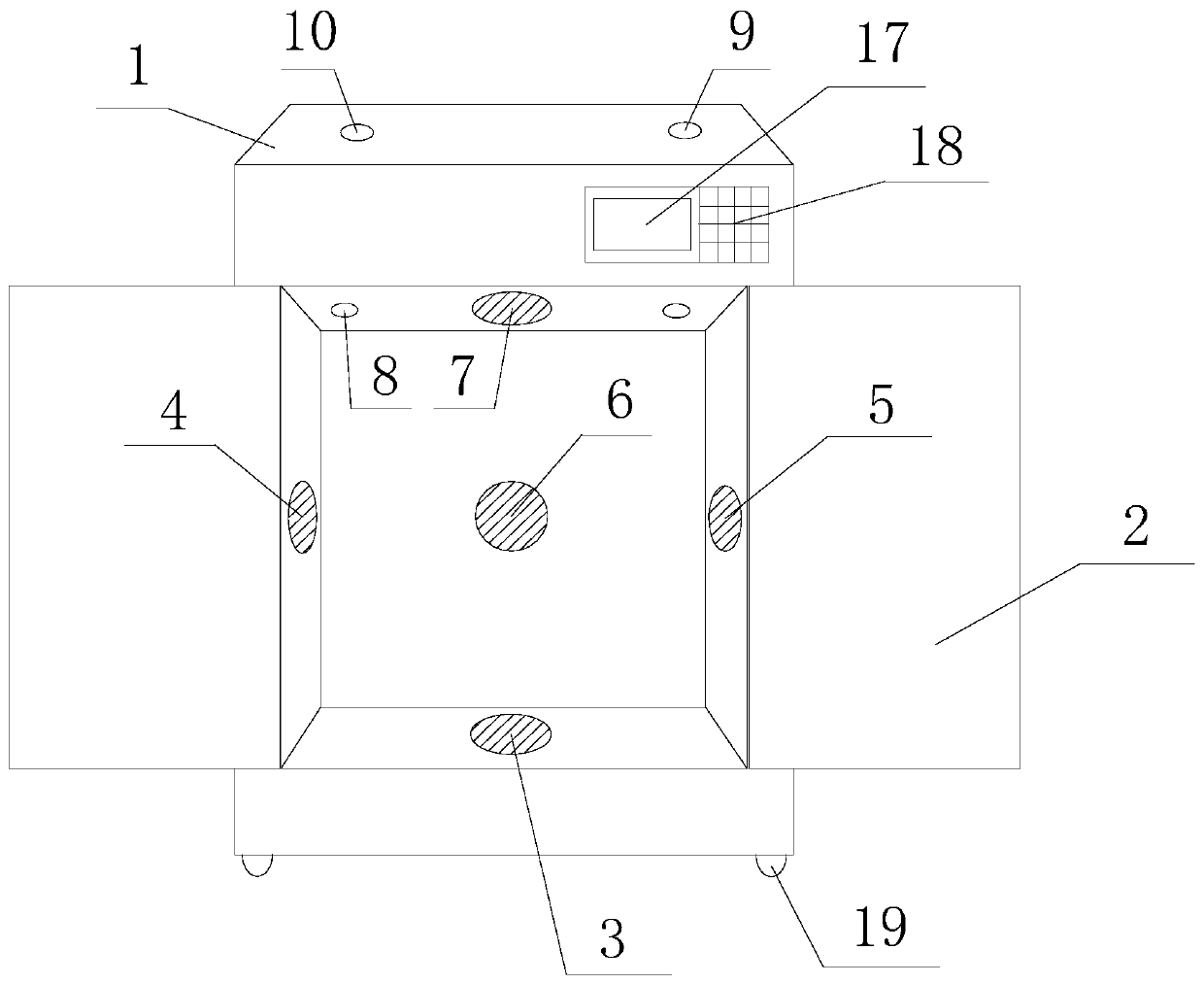

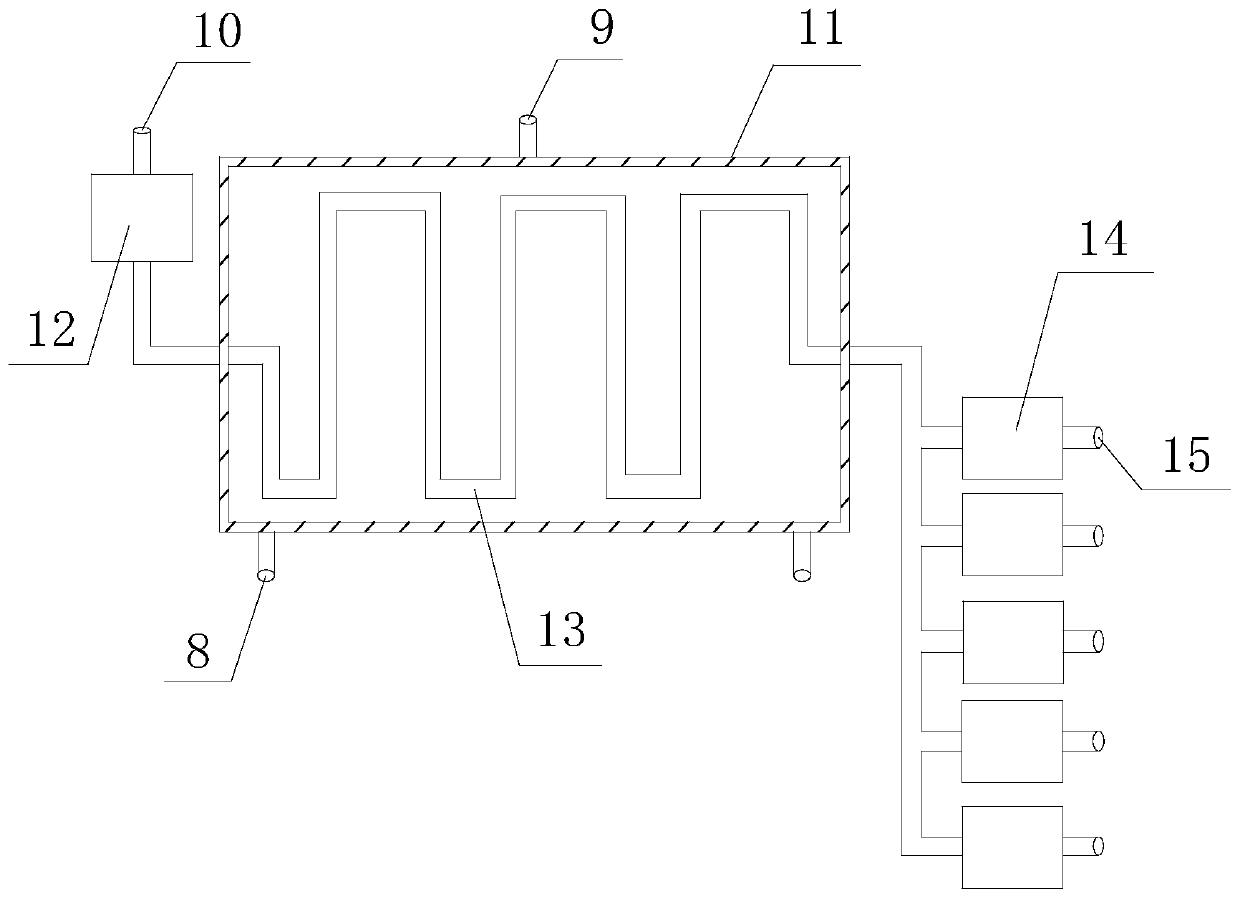

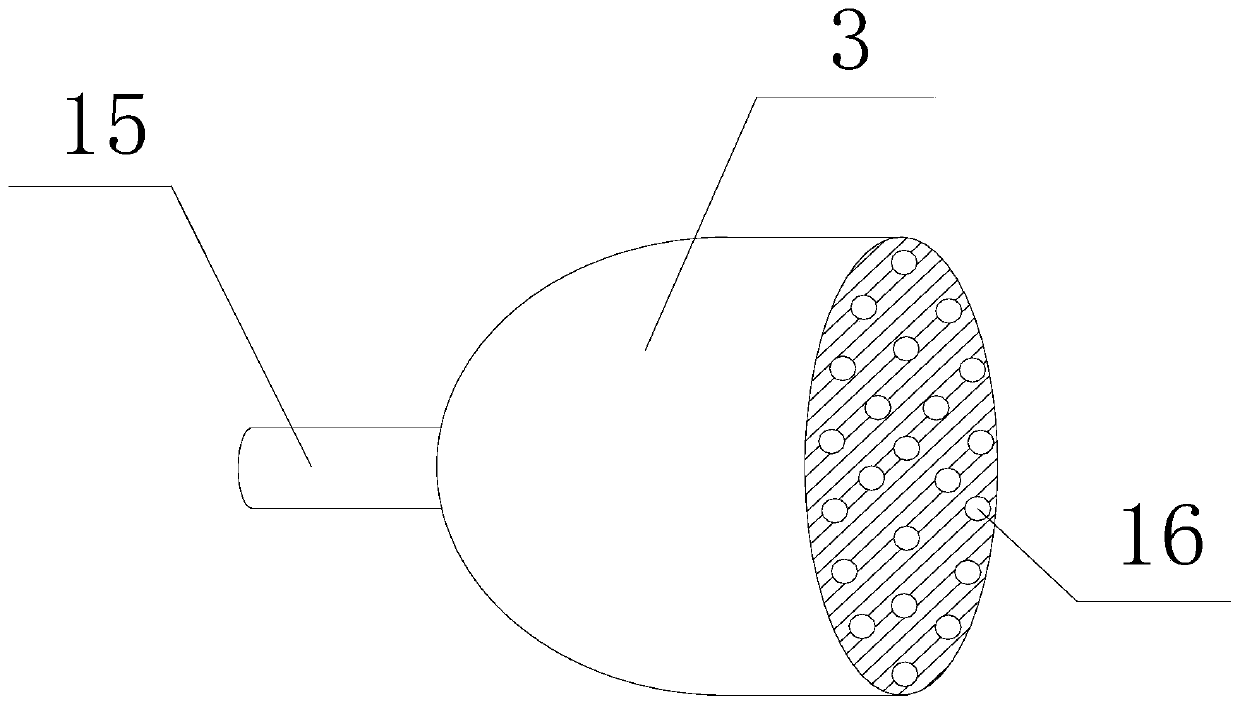

[0026] Such as Figure 1-4 As shown, an intelligent PCB oven that can realize remote monitoring, a PCB oven that can improve baking efficiency, includes an oven main body 1, an oven door 2, and an exhaust gas purification chamber 11. The oven main body 1 is provided with a baking chamber. The door 2 is arranged at the position where the front of the main body of the oven 1 faces the baking chamber, and a first heating device 3, a second heating device 4, a first heating device 3, a second heating device 4, The third heating device 5, the fourth heating device 6 and the fifth heating device 7 are also provided with an air collecting hole 8 on the top of the baking chamber, and an exhaust hole 9 and an air inlet 10 are arranged on the outer top of the oven main body 1. The inside of the oven main body 1 is provided with an exhaust gas cleaning chamber 11, and the air collecting hole 8 and the exhaust hole 9 are respectively communicated with the exhaust gas cleaning chamber 11. ...

Embodiment 2

[0029] As an optimization of the above-mentioned embodiment, a temperature detection unit is provided in the baking chamber, and the temperature detection unit is electrically connected to the microprocessor. When it is applied, the temperature detection unit can monitor the temperature in the baking chamber in real time, so as to facilitate The temperature is controlled by the microprocessor; the main body of the oven 1 is provided with a display screen 17 and function buttons 18, and the display screen 17 and the function buttons 18 are electrically connected to the microprocessor respectively. When it is used, when the remote communication fails, The temperature in the baking chamber and the baking time can also be displayed through the display screen 17, and the setting of the baking temperature and the baking time can be performed manually through the function button 18; At the same time, the air filter device can effectively filter the drawn-in external air, preventing im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com