Art ceramic plate painting and production process thereof

A technology of porcelain plate painting and art, applied in the direction of decorative art, special decorative structure, etc., can solve the problems of less ink volume, affecting the picture quality and quality of ceramic thin plates, and unable to achieve bright and vivid tones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A ceramic art porcelain plate painting of this embodiment is provided with a porcelain plate painting substrate, a background glaze layer, an inkjet layer, a secondary coloring layer and a protective glaze layer in sequence from the inside to the outside. The first-color glaze and the second-color glaze are stacked and applied on the porcelain plate painting in a weight ratio of 0.1-10.0:10.0-0.1, and fired at a high temperature above 1000 degrees Celsius to form a three-dimensional relief layer effect; the inkjet layer is superimposed On the background glaze layer, the ink of the inkjet layer is a low surface tension inkjet functional ink. Due to the low tension effect of the low surface tension inkjet functional ink, the secondary coloring layer is subjected to tension to form a three-dimensional The effect of concave layers indirectly makes the protective glaze layer have the effect of three-dimensional concave layers;

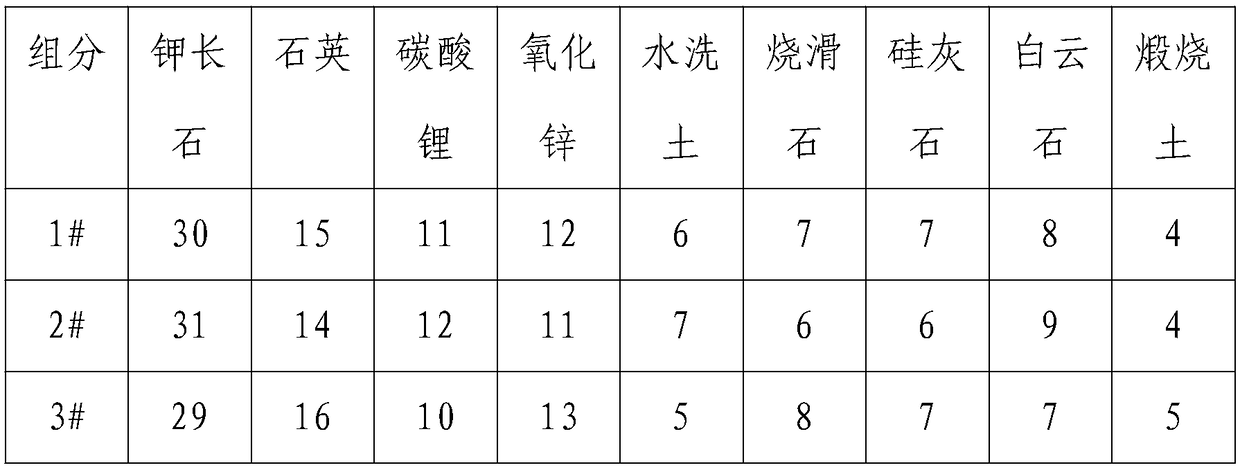

[0050] The formula composition of the first co...

Embodiment 2

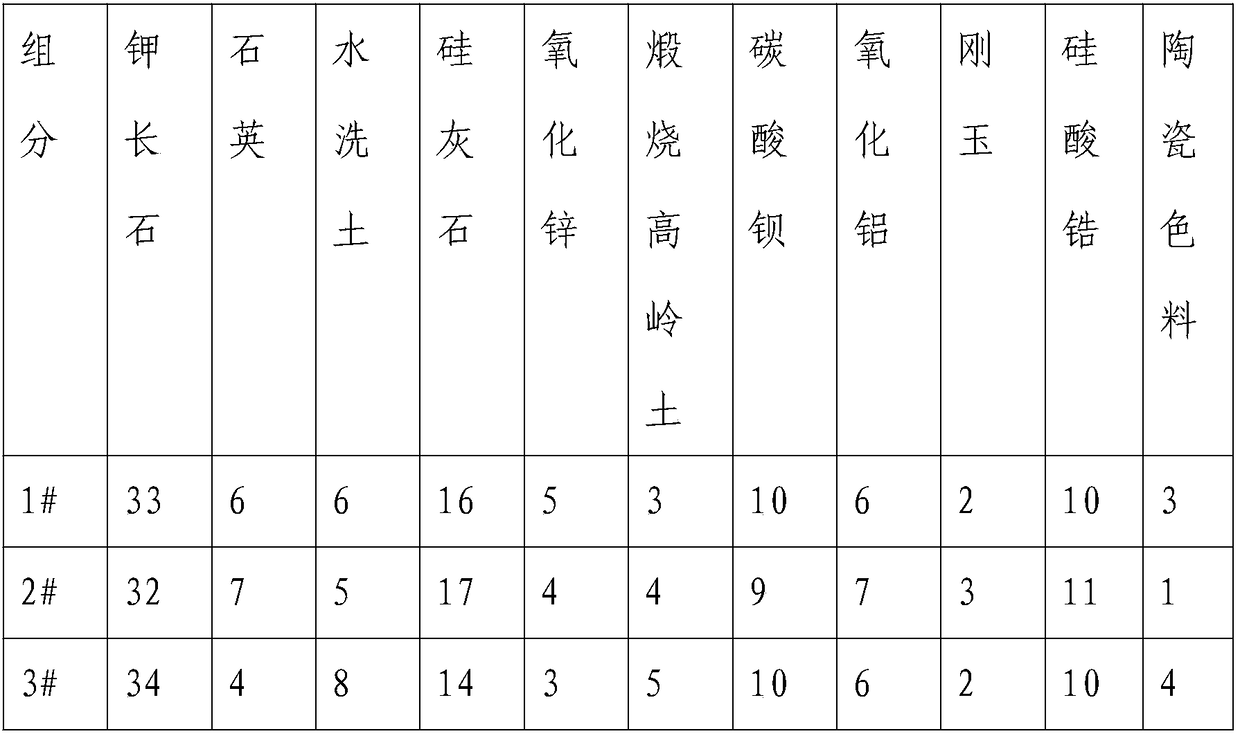

[0061] The base of the porcelain plate painting is a stoneware porcelain body, and the formula composition of the stoneware porcelain body is as shown in Table 4:

[0062] Table 4, the formula composition table of stoneware porcelain body (weight percentage, %)

[0063] component

Embodiment 3

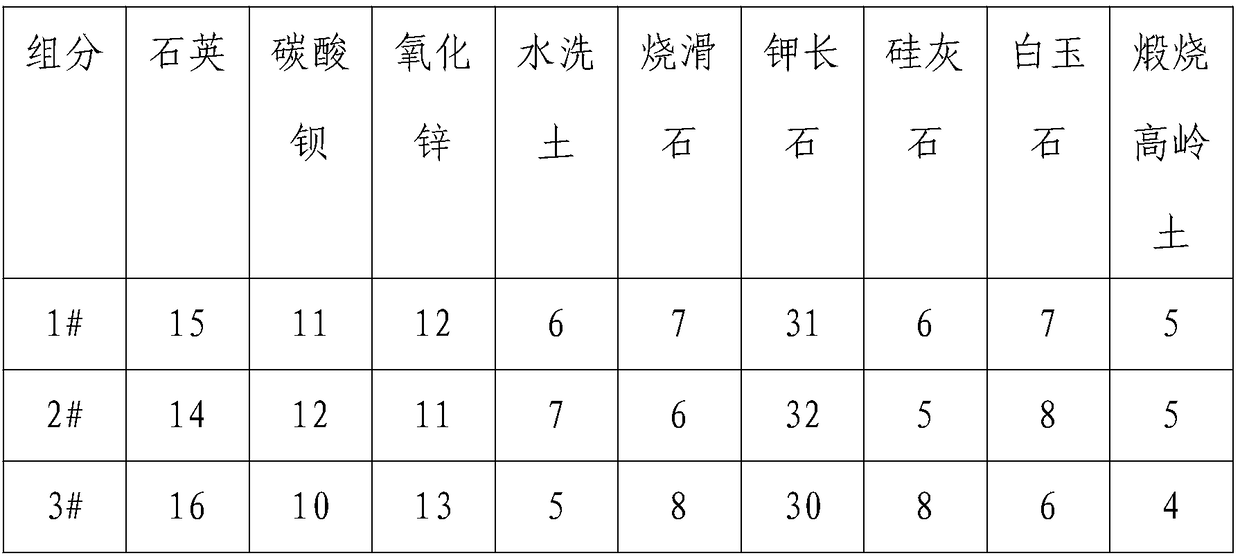

[0065] The formula composition of the background glaze is as shown in Table 5:

[0066] Table 5, the formula composition table of background glaze (weight percentage, %)

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com