UAV-based intelligent warehouse inventory system and method

A technology of intelligent warehousing and warehousing systems, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve problems such as inability to apply on a large scale, high cost, missing data, etc., to achieve seamless docking and meet inventory requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

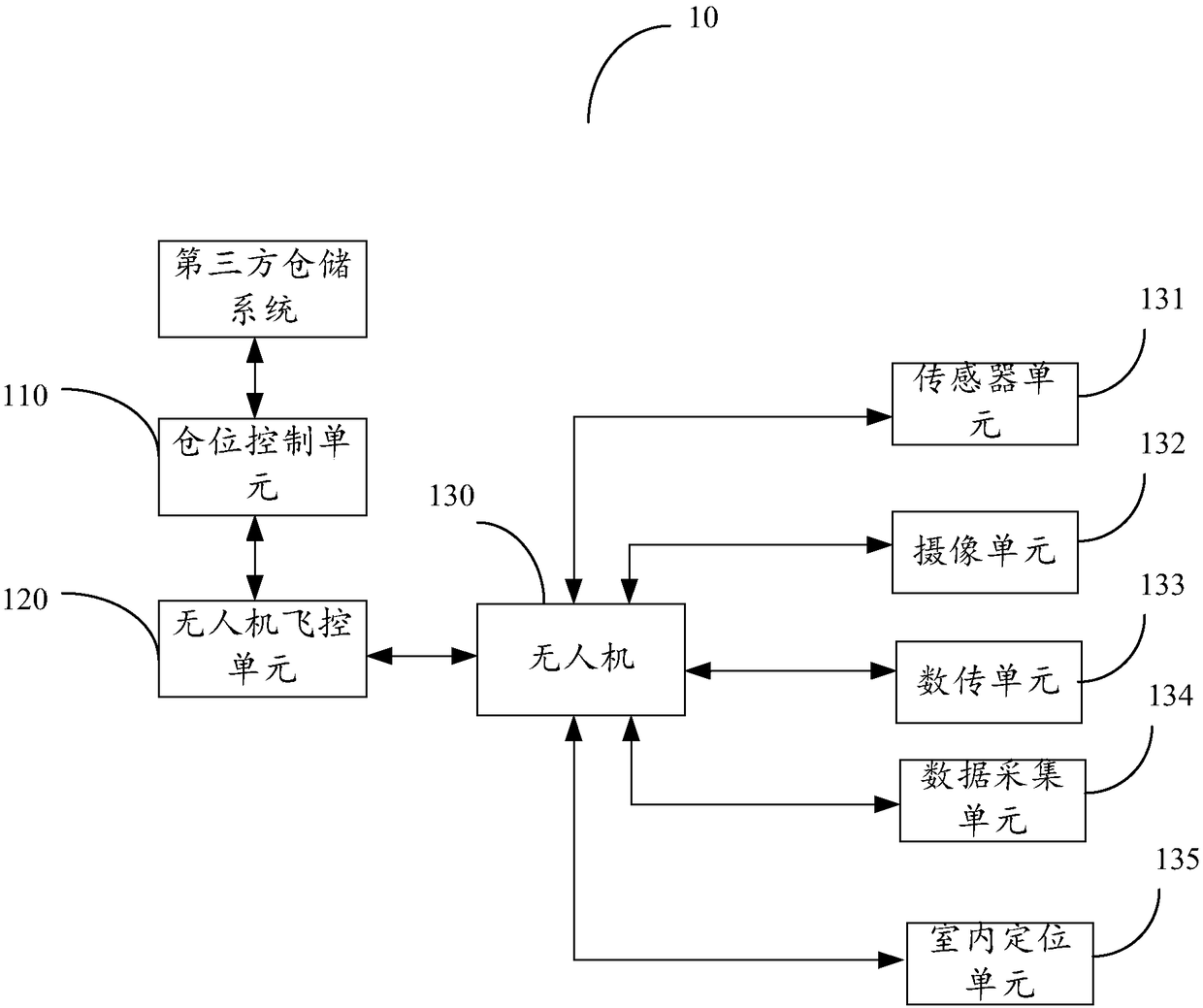

[0030] see figure 1 , the intelligent warehouse inventory system 10 based on the drone provided by the present invention includes: a warehouse control unit 110, a drone flight control unit 120 signal-connected to the warehouse control unit 110 and a signal connection to the drone control unit 120 of several drones 130 . in:

[0031] The warehouse control unit 120 is used to receive an inventory task issued by a third-party storage system, and analyze the inventory task, and at the same time plan the inventory task according to the state of the drone 130 to obtain the optimal inventory task. Inventory strategy, and push the inventory strategy to the UAV flight control unit 120, the UAV flight control unit 120 formulates the flight route of the UAV 130 according to the inventory strategy, and controls the corresponding The unmanned aerial vehicle 130 carries out inventory operation.

[0032]Specifically, when the position control unit 110 receives the inventory task list issu...

Embodiment 2

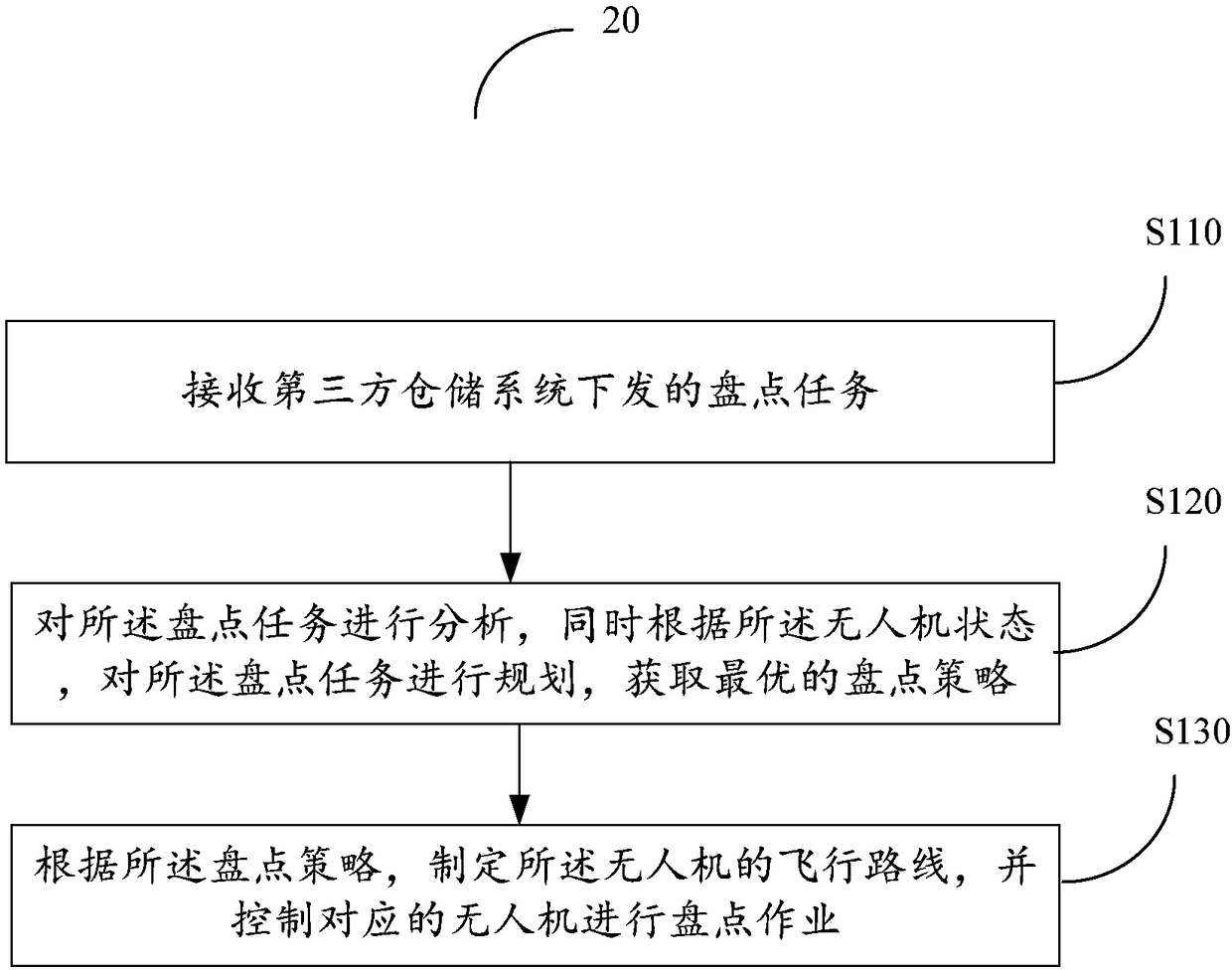

[0049] see figure 2 , the UAV-based intelligent warehouse inventory method 20 provided by the present invention comprises the following steps:

[0050] Step S110: Receive an inventory task issued by a third-party storage system.

[0051] In some preferred embodiments, signal transmission is performed with the third-party storage system through http, web service or RESTful service.

[0052] Step S120: Analyze the inventory task, and plan the inventory task according to the status of the UAV to obtain an optimal inventory strategy.

[0053] Specifically, after receiving the inventory task list issued by the third-party system, it will check according to the storage information of the goods in the task list and the current status of the drone (including whether the current drone is idle, remaining power and location information, etc.) , analyze the optimal inventory strategy (including the number of drones required for inventory, routes, etc.), and split the task list to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com