Device for heating a traction battery and method for operating a traction battery

A battery and traction motor technology, applied in the field of heating equipment for traction batteries and operating traction batteries, can solve problems such as battery performance limitation and battery performance degradation, and achieve extended durability, reduced balance requirements, and smooth heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

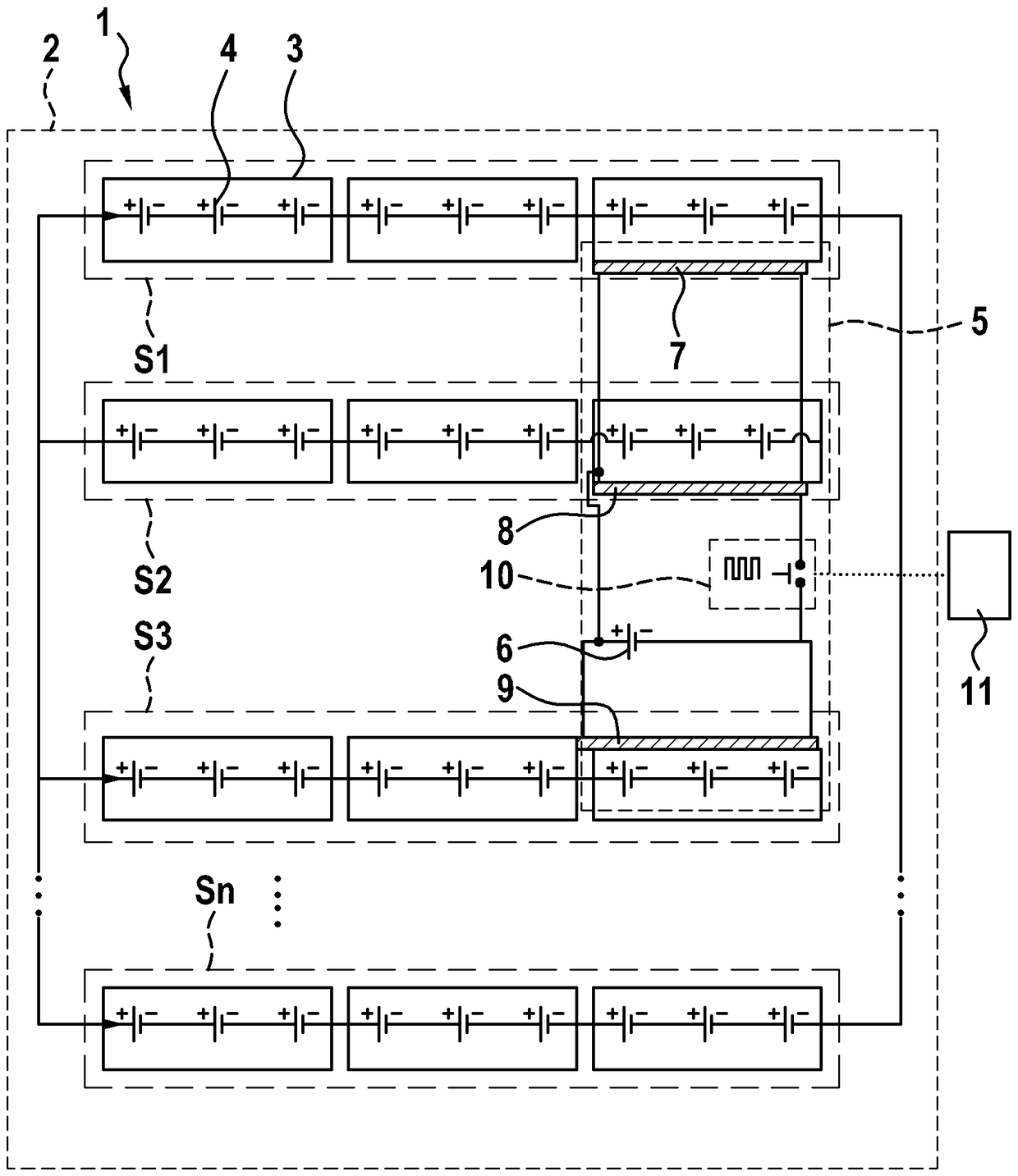

[0033] figure 1 A schematic view of an embodiment of a supply device 1 according to the invention for supplying at least one traction motor (not shown) of a vehicle with electrical energy is shown.

[0034] The supply device 1 includes a traction battery 2 connectable to the traction motor. The traction battery 2 comprises n strings S1 to Sn, each string having three battery modules 3 connected in series. Each battery module 3 includes three battery cells 4 connected in series. The traction battery 2 is a solid-state lithium-ion traction battery.

[0035] Furthermore, the supply device 1 includes a device 5 for heating the traction battery 2 . The device 5 includes a rechargeable battery 6 in the form of a starter battery. Furthermore, the device 5 includes three heating units 7 to 9 , each of which is arranged on a battery module 3 of the traction battery 2 . Alternatively, the device 5 may also include a heating unit (not shown) for further heating the battery modules 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com