High-voltage cable single-phase dry-packaging repair method

A high-voltage cable and repair method technology, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of low repair efficiency, low service life, high cable cost, etc., to save manpower, material and financial resources, increase service life, and flexible repair convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

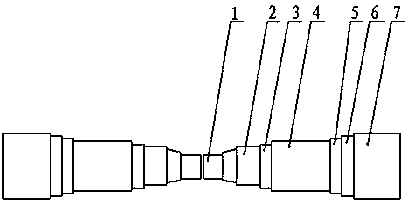

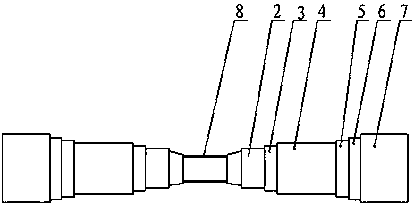

[0025] Such as figure 1 As shown, the high-voltage cable single-phase dry package repair method of the present invention, when the high-voltage cable is single-phase grounded, the damaged cable is repaired separately. First, the single-phase faulty cable needs to be pre-processed, specifically including the following steps:

[0026] 1. Strip off the outer sheath 7 of the faulty cable by 640mm;

[0027] 2. Measure from the root of the outer sheath 7, leave 50mm steel armor 6 at both ends, tie it tightly with copper binding wire, and strip off the remaining steel armor 6;

[0028] 3. Retain 50mm inner sheath 5 at both ends of the faulty cable, and strip off the rest of the inner sheath 5;

[0029] 4. Leave 300mm copper shielding 4 at both ends of the faulty cable, and strip off the rest of the copper shielding 4;

[0030] 5. Leave 150mm semi-conductive layer 3 at both ends of the faulty cable, and strip off the remaining semi-conductive layer 3;

[0031] 6. Select the appropr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com