Method for producing a base body of a turbine blade

A technology of moving blades and bases, which is applied in the direction of blade support components, engine functions, engine components, etc., and can solve problems such as resonance frequency excitation frequency deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

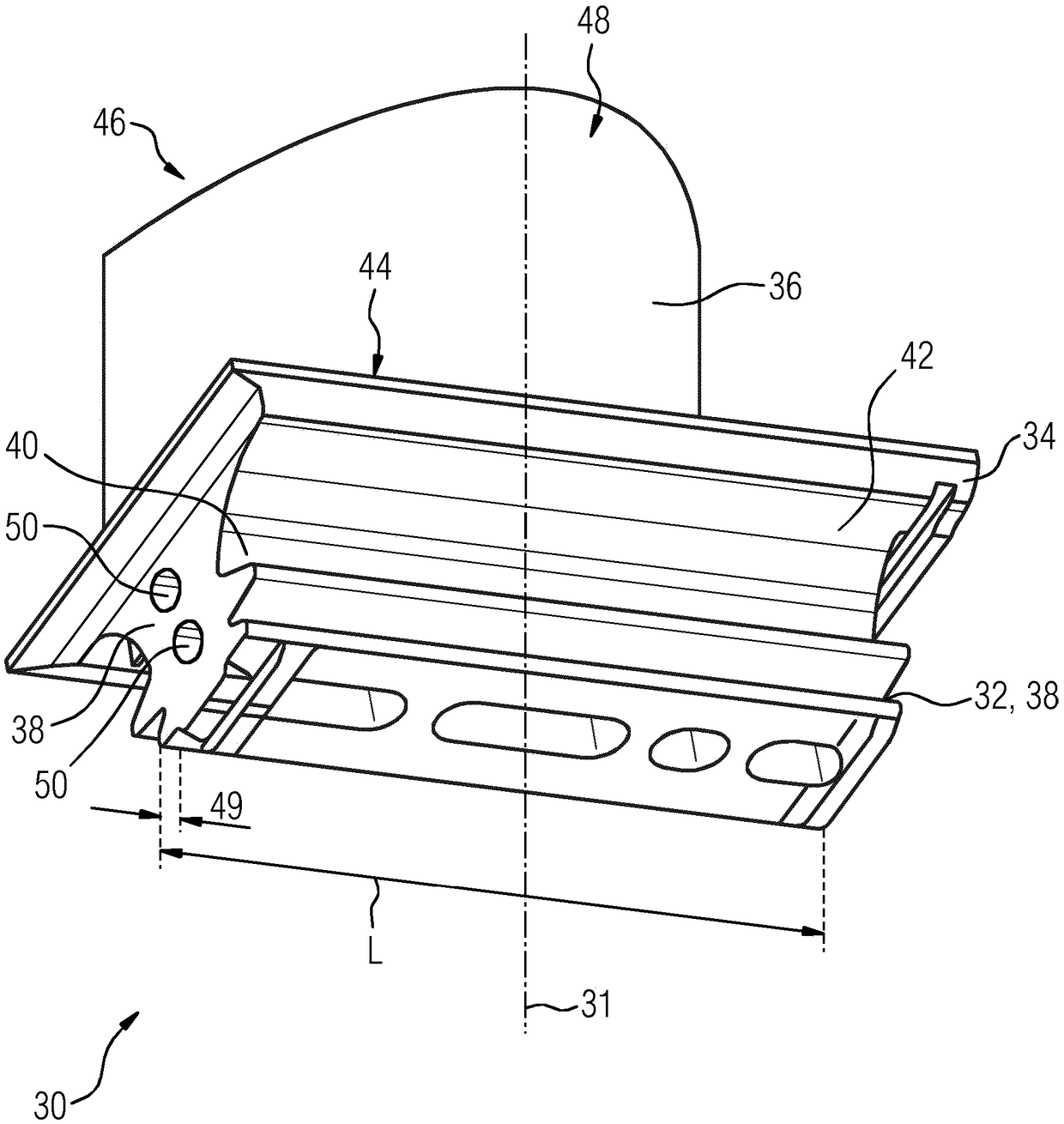

[0022] figure 1 A method 10 according to the invention is shown. Base body 30 (for making turbine rotor buckets) image 3 ) method 10 includes providing, in a first step 12 , a base body 30 of a turbine rotor bucket. The base body 30 includes, in sequence, a bucket root 32 , a platform 34 and a bucket airfoil 36 along a virtual longitudinal axis 31 .

[0023] The bucket root 32 has a fir-tree profile when viewed perpendicular to the planar end face 38 of the bucket root 32 and merges into the underside 42 of the platform 34 via a so-called bucket neck 40 . The platform includes a hot gas side 44 opposite the bottom side 42 to which the bucket airfoil 36 is monolithically connected. The bucket airfoil 36 is formed in the shape of a drop and is aerodynamically curved to form a pressure side 46 and a suction side 48 .

[0024] The bucket root 32 extends over a length L between two planar end faces 38 arranged axially opposite each other.

[0025] In the second manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com