Photosensitive resin composition, and black column spacer and color filter using same

A technology of photosensitive resin and composition, applied in the field of color filters, can solve the problems of UV transmittance deterioration, unfavorable photocuring of black column spacers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0194] The photopolymerization initiator was dissolved in the solvent in the composition given in Table 1, and the solution was stirred at room temperature for 2 hours. Subsequently, a binder resin and a photopolymerizable monomer were added thereto, and the mixture was stirred again at room temperature for 2 hours. Then, a colorant was added thereto, the mixture was stirred at room temperature for 1 hour, a silane-based coupling agent was added thereto as another additive, and the obtained mixture was stirred at room temperature for 1 hour. The resulting solution was filtered three times to remove impurities, thereby preparing a photosensitive resin composition according to Example 1.

[0195] [Table 1]

[0196] (unit: gram)

[0197]

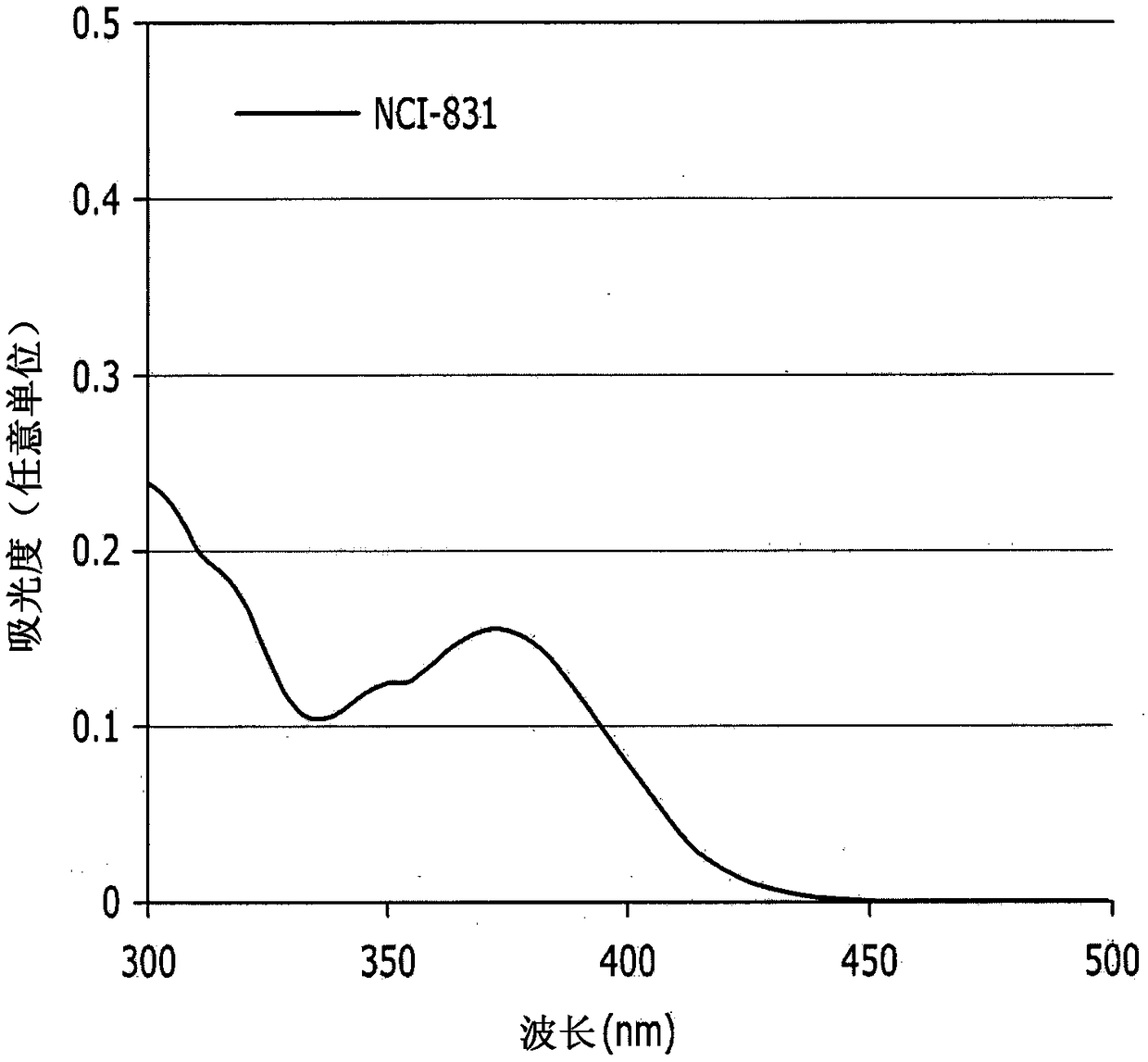

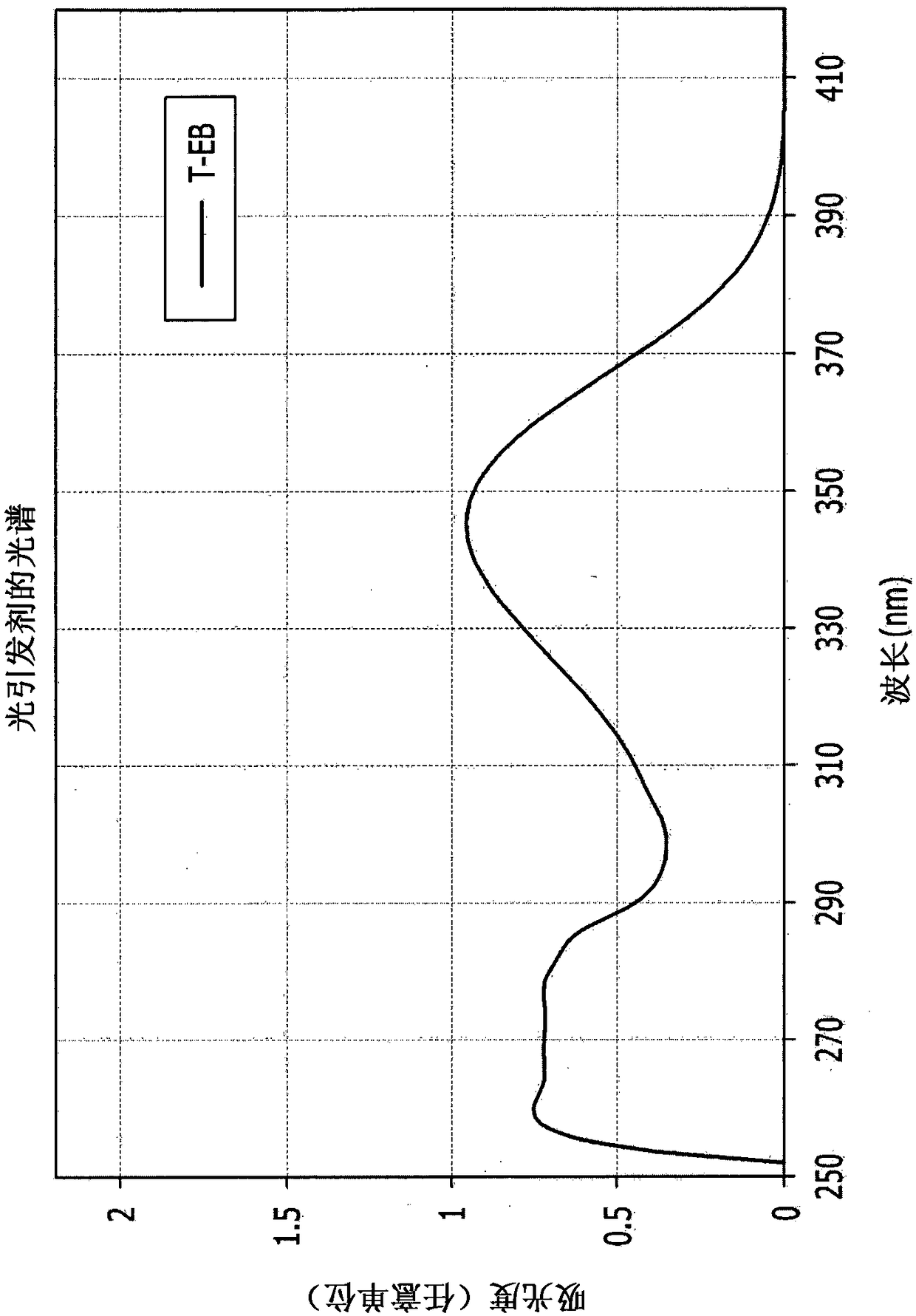

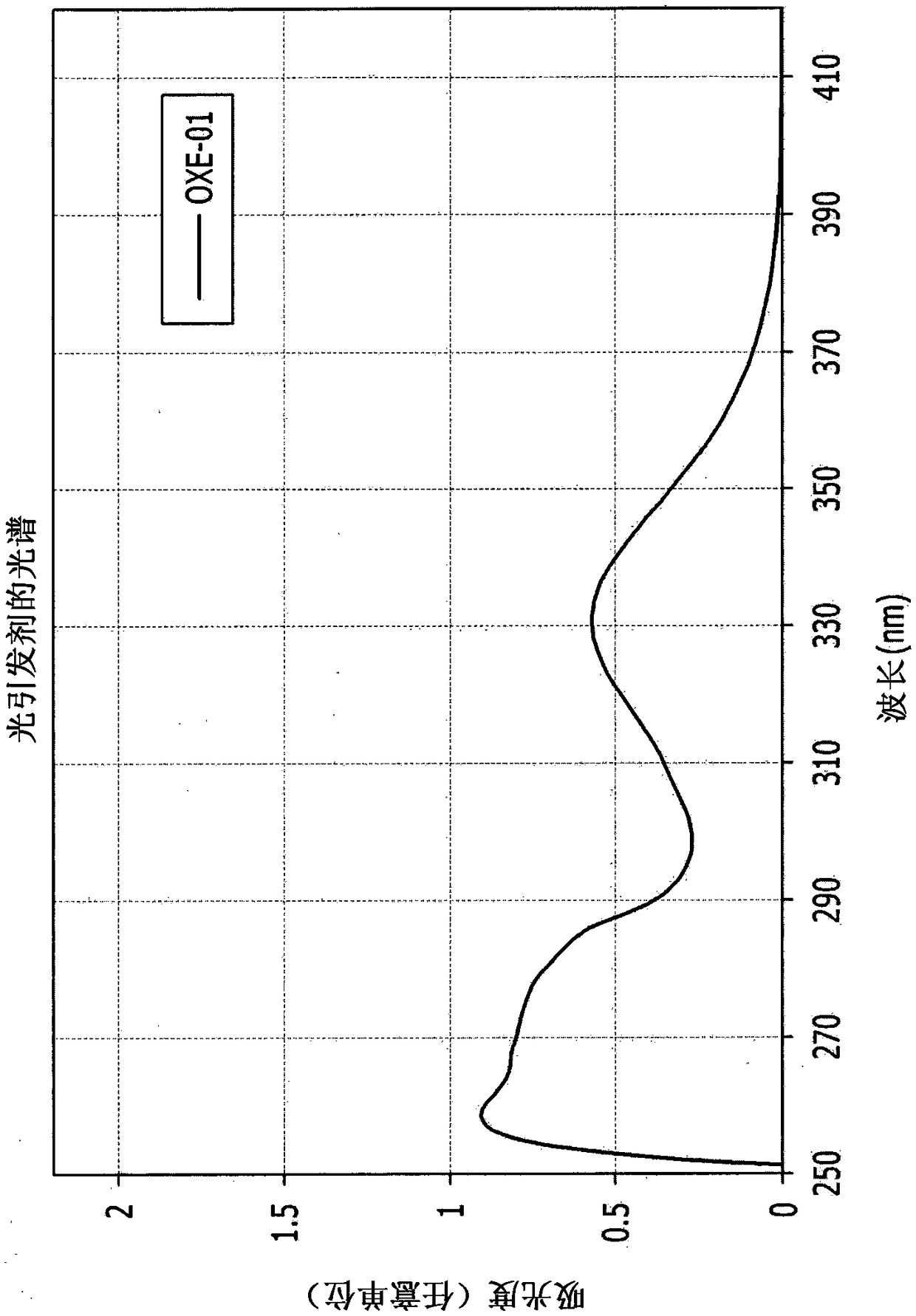

[0198] (In Table 1, NCI831 has the maximum absorbance at 380nm, while TEB has the maximum absorbance at 345nm)

[0199] (In Table 1, the colorants have maximum transmission at 400nm)

[0200] (In Table 1, the pigment solids are contained...

example 2

[0202] A photosensitive resin composition according to Example 2 was prepared according to the same method as Example 1 except for using the following components to have the composition shown in Table 2.

[0203] [Table 2]

[0204] (unit: gram)

[0205]

[0206] (In Table 2, NCI831 has the maximum absorbance at 380nm, while TEB has the maximum absorbance at 345nm)

[0207] (In Table 2, the colorants have maximum transmission at 400nm)

[0208] (In Table 2, pigment solids are contained in an amount of 10% by weight based on the total amount of the pigment dispersion liquid)

example 3

[0210] A photosensitive resin composition according to Example 3 was prepared according to the same method as Example 1 except using the following components to have the composition shown in Table 3.

[0211] [table 3]

[0212] (unit: gram)

[0213]

[0214]

[0215] (In Table 3, NCI831 has the maximum absorbance at 380nm, while TEB has the maximum absorbance at 345nm)

[0216] (In Table 3, the colorants have maximum transmission at 400nm)

[0217] (In Table 3, pigment solids are included in an amount of 10% by weight based on the total amount of the pigment dispersion liquid)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com