Dairy product packaging bottle and preparation method thereof

A technology for packaging bottles and dairy products, applied in the field of dairy packaging bottles and packaging materials for white milk, can solve the problems of lack of light-blocking properties and the influence of light-blocking contents, and achieve the effect of improving the display image of the terminal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] 1. Preparation of light-blocking masterbatch

[0033] In the present invention, the light-blocking masterbatch is prepared first. The composition of the light-blocking masterbatch of the present invention comprises based on 100 parts by weight of the total weight of the light-blocking masterbatch:

[0034] HDPE resin: 35-40 parts by weight; titanium dioxide: 55-65 parts by weight; polyethylene wax dispersant: 1-3 parts by weight; ester antioxidant: 0-1 parts by weight.

[0035] After putting the above raw materials into a stirring tank and stirring evenly, the mixed material is added into an extruder, and the mixed material is melted and extruded, then pelletized and dried. The bulk density of the obtained light-blocking masterbatch is 1.2kg / m 3 , The ash content is 64-74%.

[0036] In the present invention, products sold on the market can also be used directly, for example, the product of Holland Color Co., Ltd. whose trademark is 473-30-25424.

[0037] 2. Preparat...

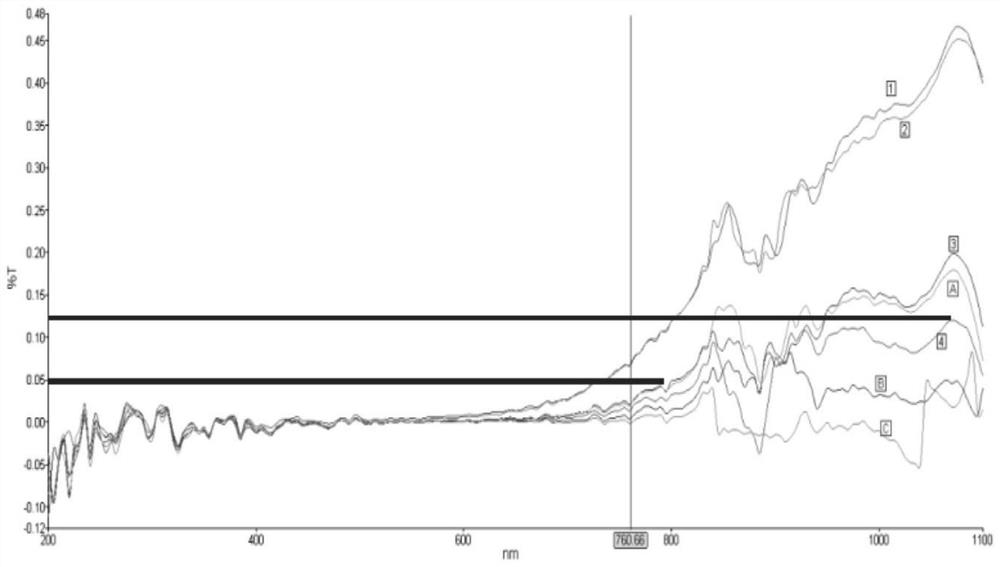

Embodiment 1

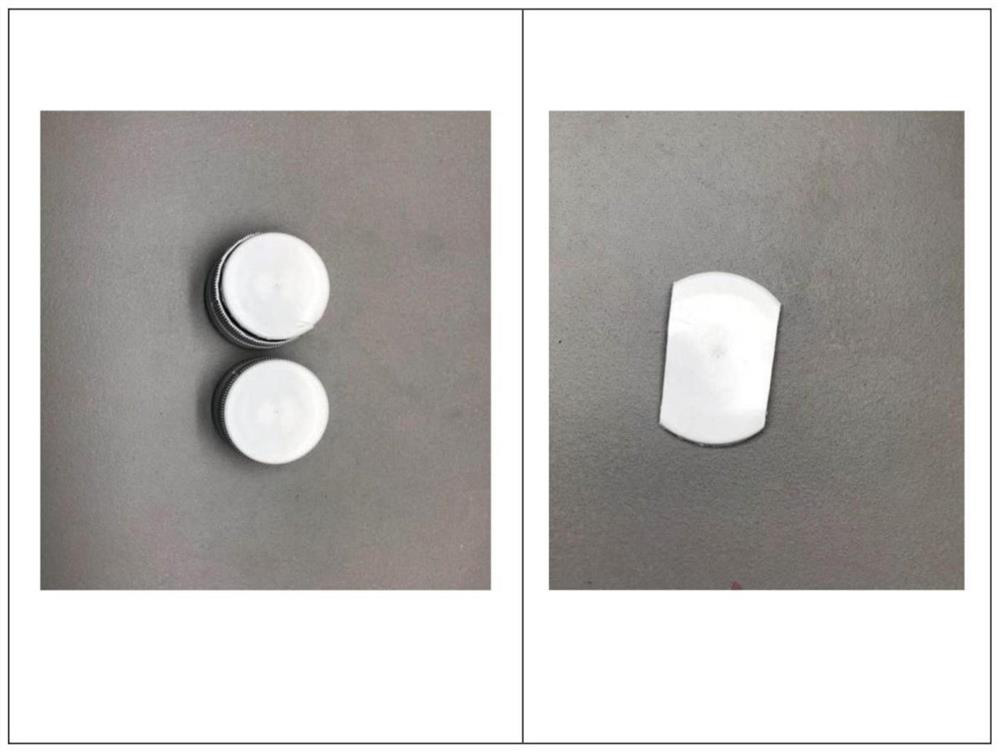

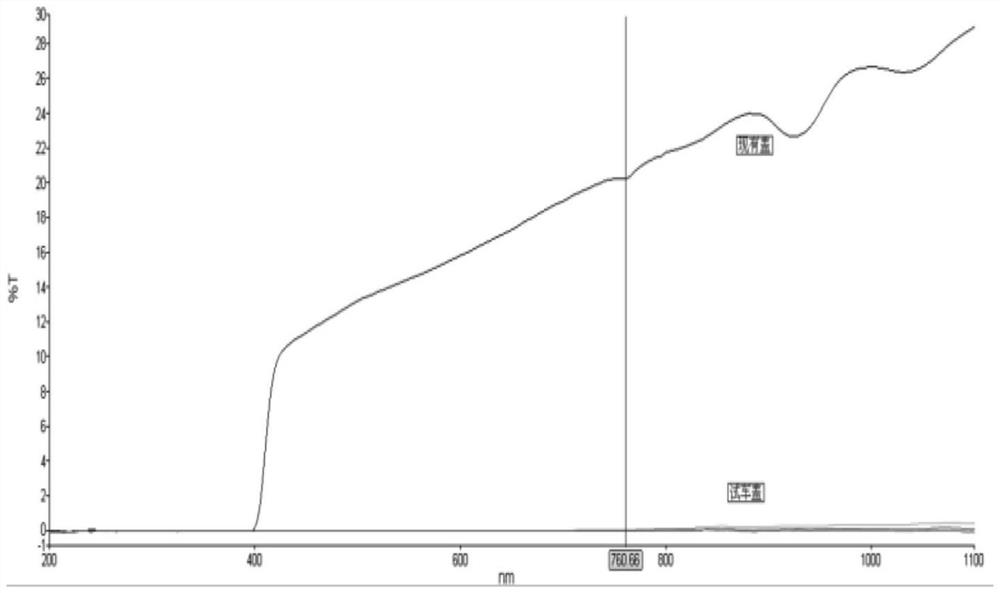

[0071] Use the light-blocking masterbatch with the brand number 473-30-25424 from Holland Color Company and the HDPE bottle cap raw material with the brand name M430A from South Korea’s Total Company, so that the light-blocking masterbatch can be added to the light-blocking HDPE bottle cap in terms of raw material weight. The content in the bottle is 5% by weight, and the capping machine equipment is used to finally compress and mold through processes such as screw mixing and heating to prepare bottle caps. The finally obtained light-blocking HDPE bottle cap of Example 1 has a weight of 3.3 g and a cap size of 0.95 mm.

[0072] The above-mentioned light-blocking HDPE bottle cap and PET light-blocking bottle body are assembled into a dairy packaging bottle.

[0073] Experiment and evaluation of the influence of bottle caps on the taste acceptability of white milk products

[0074] Put the same white milk sample into the packaging of the control group (non-light-blocking bott...

Embodiment 2

[0099] Except that the content of the light-blocking masterbatch in the light-blocking HDPE bottle cap is 6% by weight based on the weight of raw materials, other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com