High-shear emulsification tank

A high-shear emulsification and emulsification tank technology, which is applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve problems such as the weight of stirring motors and shearing motors, unreasonable structural design, and large vibration of emulsification tanks , to achieve the effect of reasonable structure setting, good practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

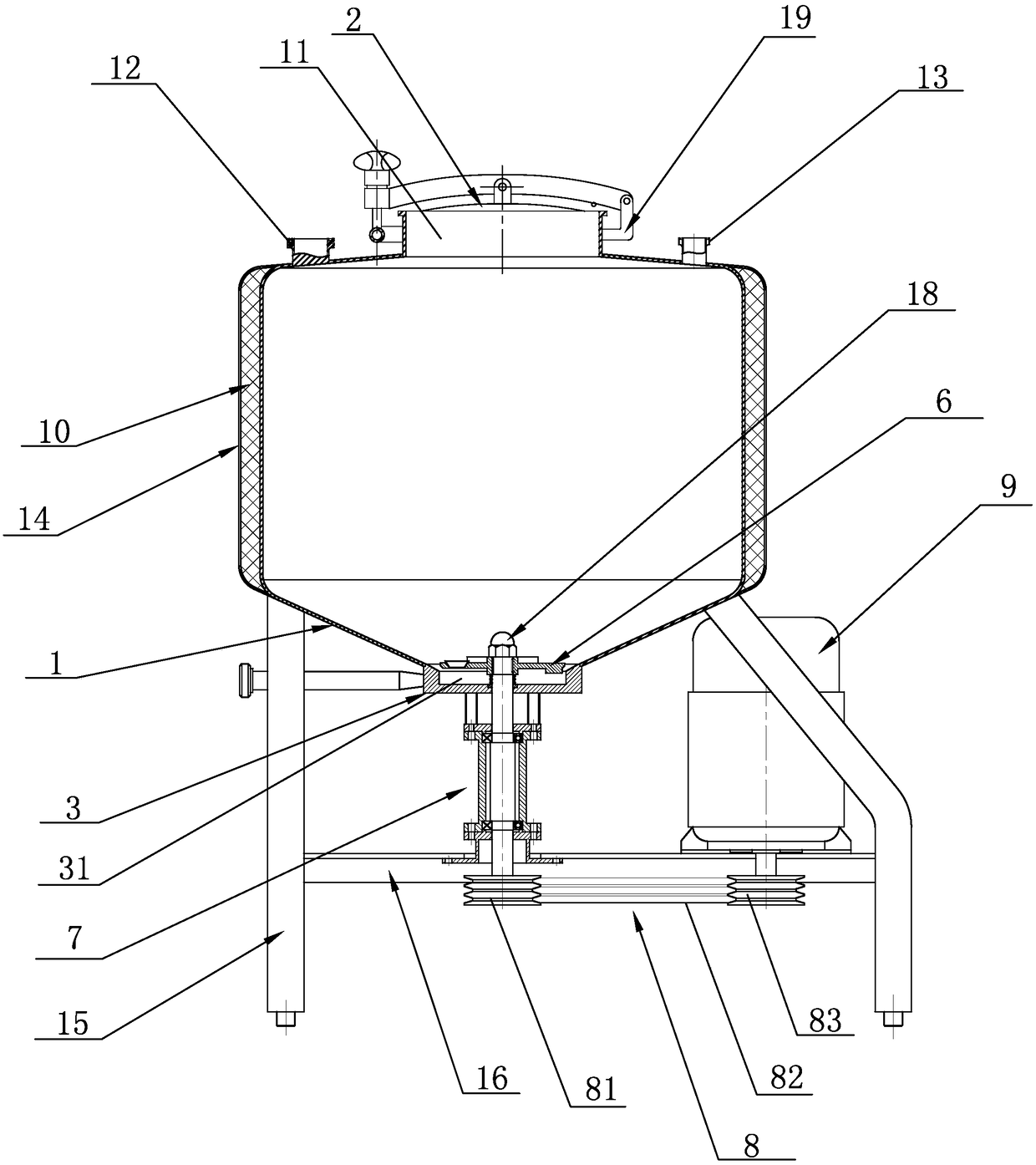

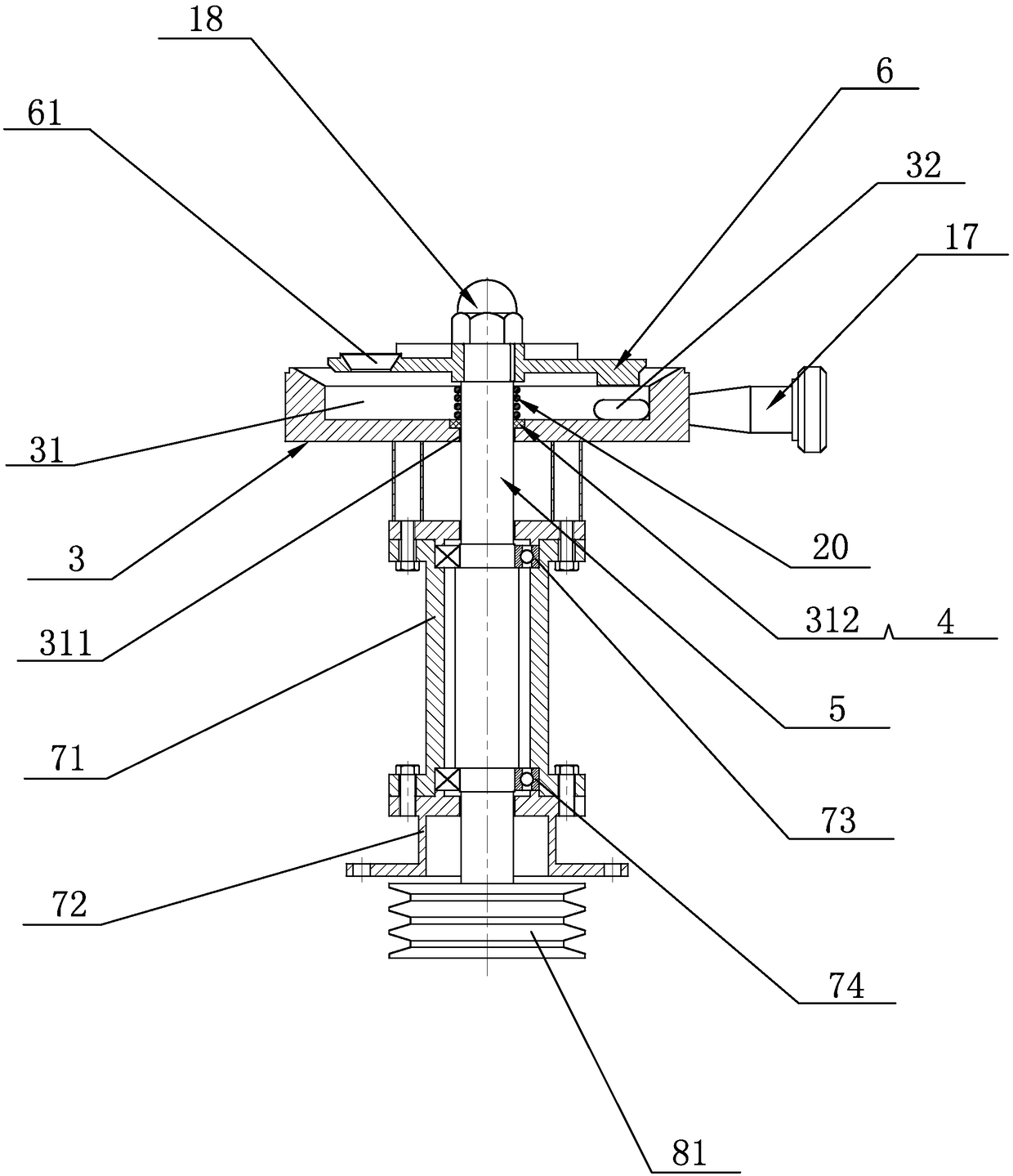

[0020] see figure 1 and figure 2 , a high-shear emulsification tank disclosed in the present invention, comprising an emulsification tank body 1, a material inlet 11 is arranged at the top middle of the emulsification tank body 1, and a flip mechanism 2 is arranged on the material inlet 11, and the emulsification tank The top left end of the main body 1 is integrally provided with a first shearing motor installation platform 12, and the top right end of the emulsification tank body 1 is integrally provided with a second shearing motor installation platform 13, and the lower end of the emulsification tank body 1 is fixedly provided with a tank body Base 3, a stirring blade installation cavity 31 is arranged in the tank body base 3, and a stirring shaft installation through hole 311 is arranged at the middle part of the bottom surface of the stirring blade installation cavity 31, and the upper port of the stirring shaft installation through hole 311 is set There is a sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com