Full-automatic glasses machining glue frame machine

A glue machine, fully automatic technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of manual operation and low efficiency, and achieve the effect of improving accuracy, increasing speed and reducing human operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

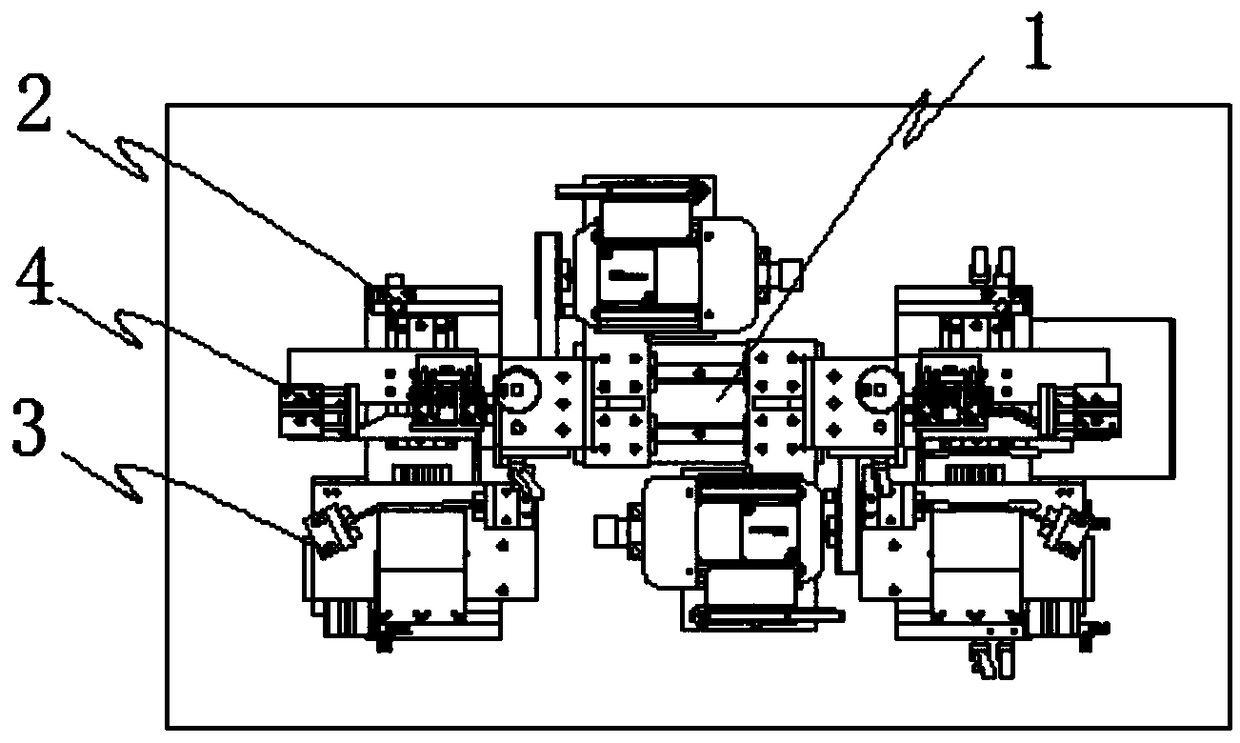

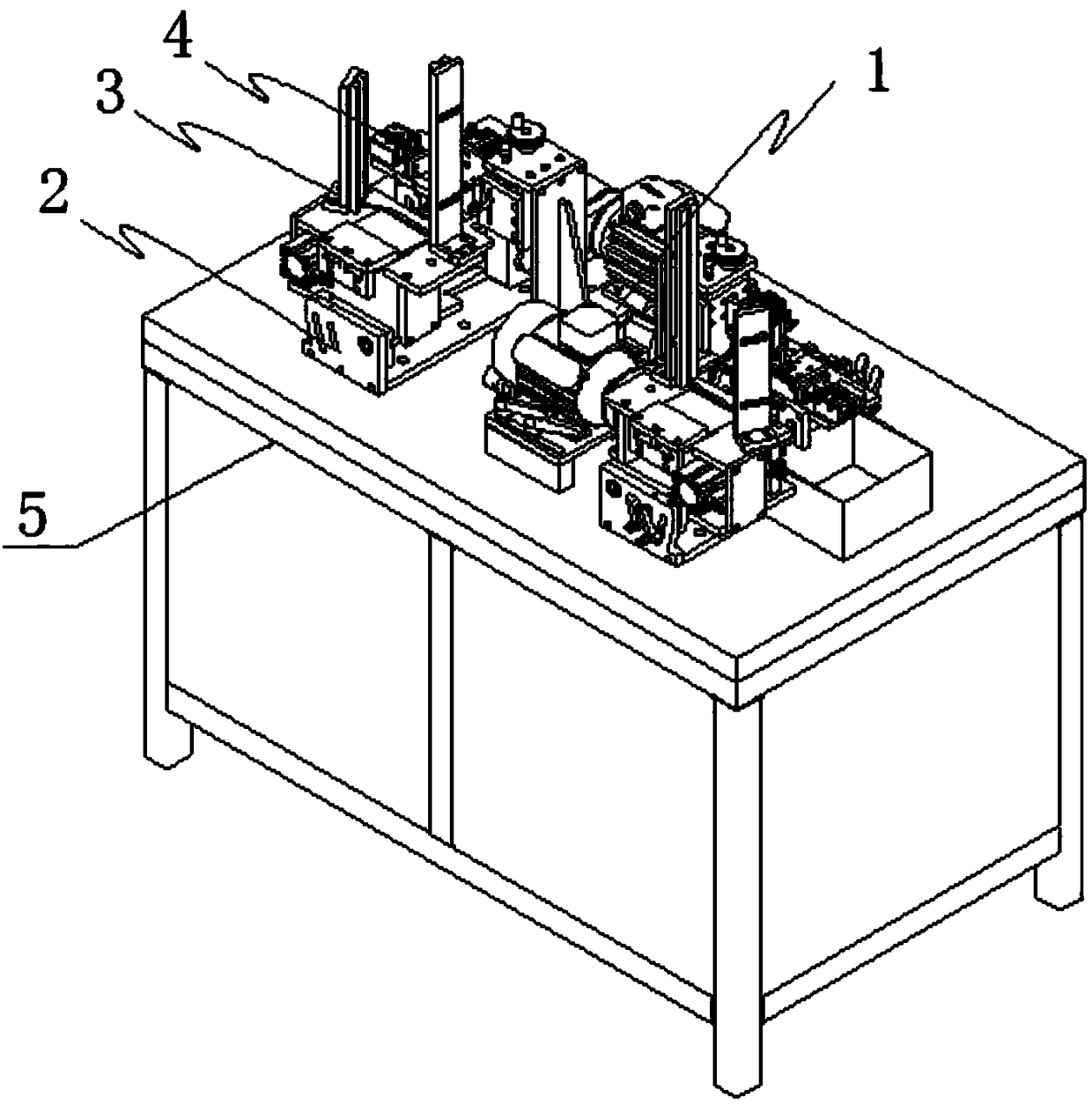

[0039] A kind of fully automatic processing glasses plastic frame machine that embodiment 1 of the present invention provides, please refer to figure 1 As shown, it includes a platform 5 and a PLC. The platform 5 is provided with a cutting assembly 1; both sides of the cutting assembly 1 are equipped with a feeding and conveying assembly 3, an angle adjustment assembly 2 and a material positioning assembly 4 with the same structure. ;

[0040] see figure 2 As shown, the angle adjustment assembly 2 is arranged on the top surface of the platform 5; the feeding conveying assembly 3 is arranged on the top surface near one end of the angle adjustment assembly 2, and the material positioning assembly 4 is arranged on the top surface near the The top surface of the other end of the angle adjustment assembly 2; the output end of the feeding and conveying assembly 3 is arranged in cooperation with the input end of the material positioning assembly 4; the material positioning assembly...

Embodiment 2

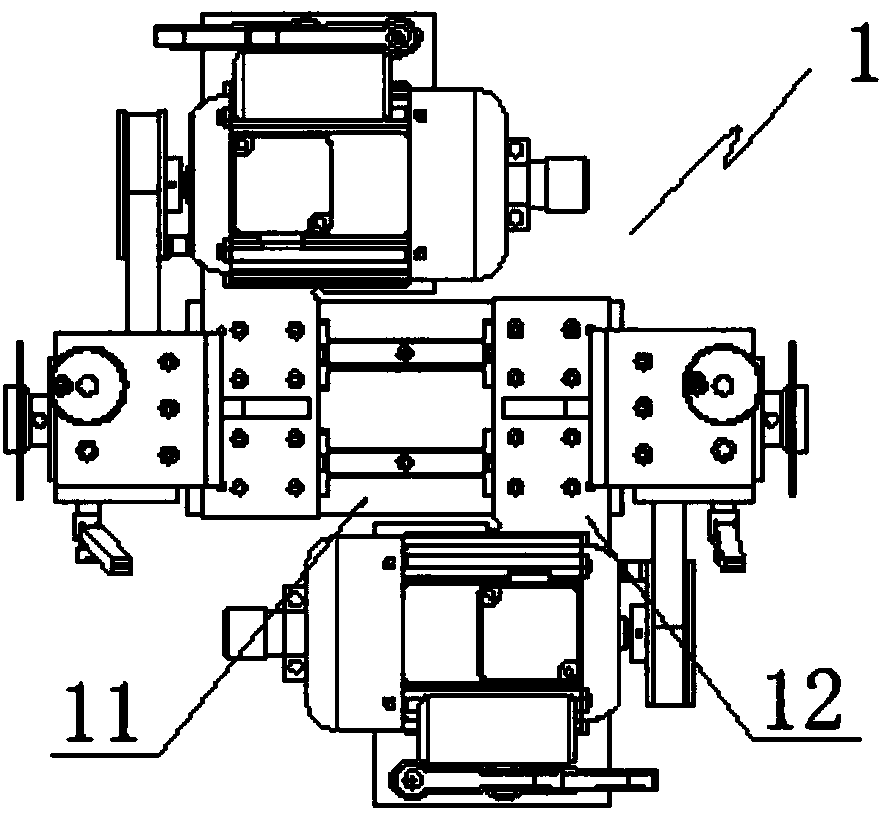

[0044] A kind of fully automatic processing glasses frame machine provided by Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is that please refer to image 3 As shown, the cutting assembly 1 includes a base plate 11 fixedly connected to the top surface of the stand 5; two slide plates 12 are slidably connected to the base plate 11, and the two slide plates 12 have the same structure and are arranged opposite to each other; see Figure 4 As shown, the two sides of the bottom plate 11 are respectively connected with the first fine-tuning thread pair 16 through the connecting block, and the first fine-tuning thread pair 16 is connected with the bottom of the slide plate 12; the slide plate 12 is provided with a first through groove 19; a fixed block 18 fixedly connected to the top surface of the stand 5 is provided directly below the first through groove 19; the slide plate 12 is connected with the fixed block 18 through two first fast...

Embodiment 3

[0049] A kind of fully automatic processing glasses frame machine provided by embodiment 3 of the present invention is basically the same as embodiment 2, the difference is that please refer to Figure 5 As shown, in order to improve the accuracy of processing, one side of the vertical plate 13 is vertically provided with a fixed plate 114; one side of the fixed plate 114 is in contact with the end surface of the adjustment block 111; The screw 116 is connected with the adjusting block 111; the fixing plate 114 is provided with a second through groove 115 penetrating both sides; the second fastening screw 116 passes through the second through groove 115; the goal of.

[0050] During use, first unscrew the second fastening screw rod 116, and adjust the height of the milling cutter. After the adjustment, tighten the second fastening screw rod 116.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com