Manufacturing process of finned tube air cooler and finned tube air cooler

A finned tube type and manufacturing process technology, which is applied in the field of petrochemical and coal chemical equipment, can solve problems such as leakage, leakage accidents, and deep hole welding that cannot ensure that the weld seam at the end of the pipe has sufficient section thickness, so as to ensure safe operation, Guarantee the effect of safe use and high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] According to one aspect of the present invention, a manufacturing process of a finned tube air cooler, the manufacturing process includes the following steps:

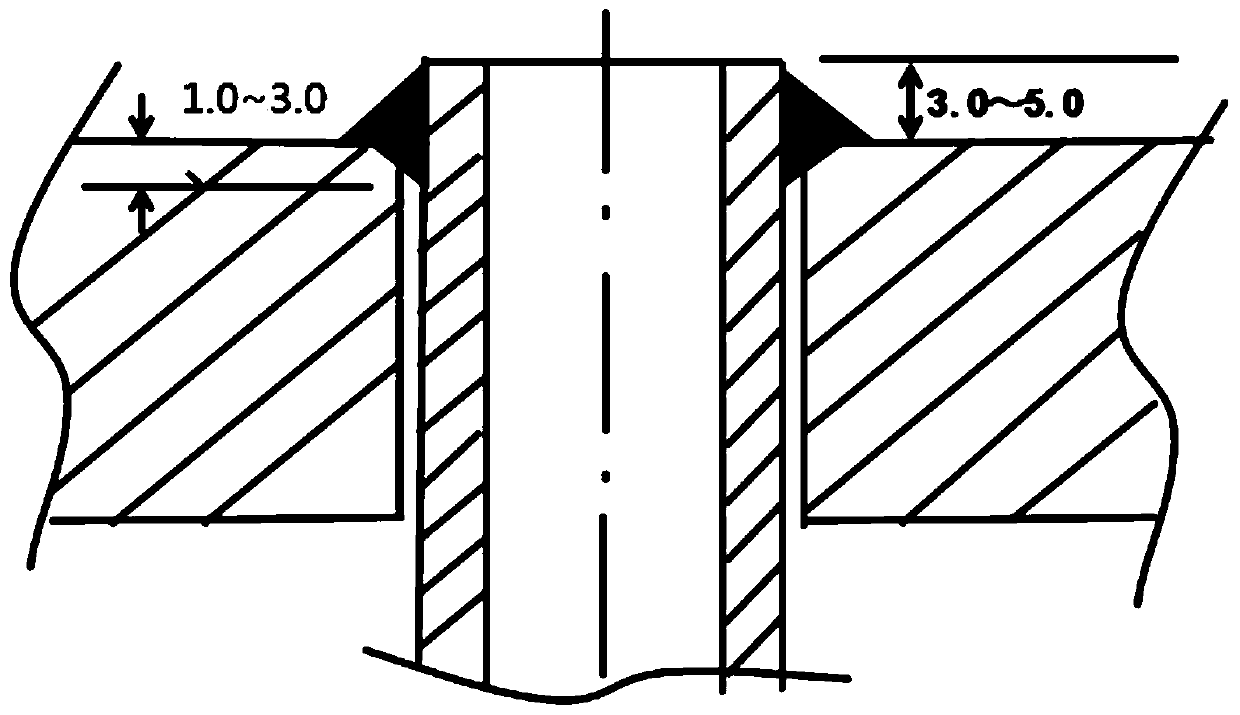

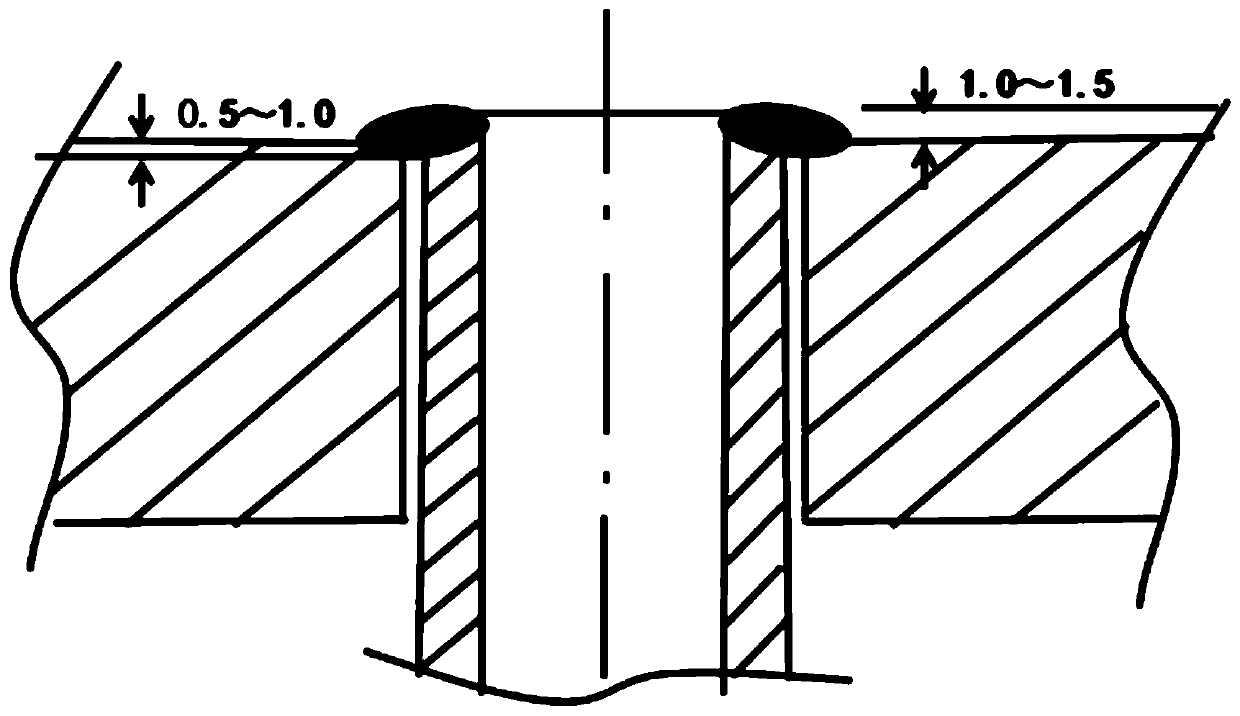

[0046] (a) Tube head welding: Assemble the finned tube and the tube sheet and weld the tube head and the tube sheet of the finned tube together by groove welding,

[0047] (b) Tube box welding: The tube plate welded with finned tubes, the symmetrically arranged plugging plates and the upper and lower cover plates are assembled and welded, and then the connecting tube and side plate are welded, and at the same time, the welding process of the tube box is carried out separately. Step heat treatment to obtain a welded finned tube air cooler.

[0048] The manufacturing process of the finned tube air cooler provided by the present invention, the manufacturing process first assembles the finned tube and the tube plate and welds the tube head of the finned tube and the tube plate together by using a groove welding meth...

Embodiment 2

[0077] According to one aspect of the present invention, a finned tube air cooler is manufactured by the above-mentioned manufacturing process of the finned tube air cooler.

[0078] In the finned tube air cooler provided by the present invention, both the tube head and the tube box of the finned tube type air cooler have high welding quality, which effectively alleviates the failure of deep hole welding to ensure that the weld seam at the tube end has a sufficient cross-sectional thickness. As a result, there are many abnormal corrosion problems in the welding seam of the pipe head that lead to leakage accidents, which can effectively ensure the safe use and operation of the high-pressure air cooler.

[0079] To sum up, the manufacturing process of the finned tube air cooler provided by the present invention, the manufacturing process first assembles the finned tube and the tube plate and uses the method of groove welding to weld the tube head of the finned tube and the tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com