Fully-automatic assembly equipment and method for photoelectric switch

A technology for photoelectric switches and assembly equipment, applied in assembly machines, metal processing equipment, metal processing, etc., can solve problems such as low production efficiency, high production cost, and poor quality, and achieve automatic transportation, low production cost, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

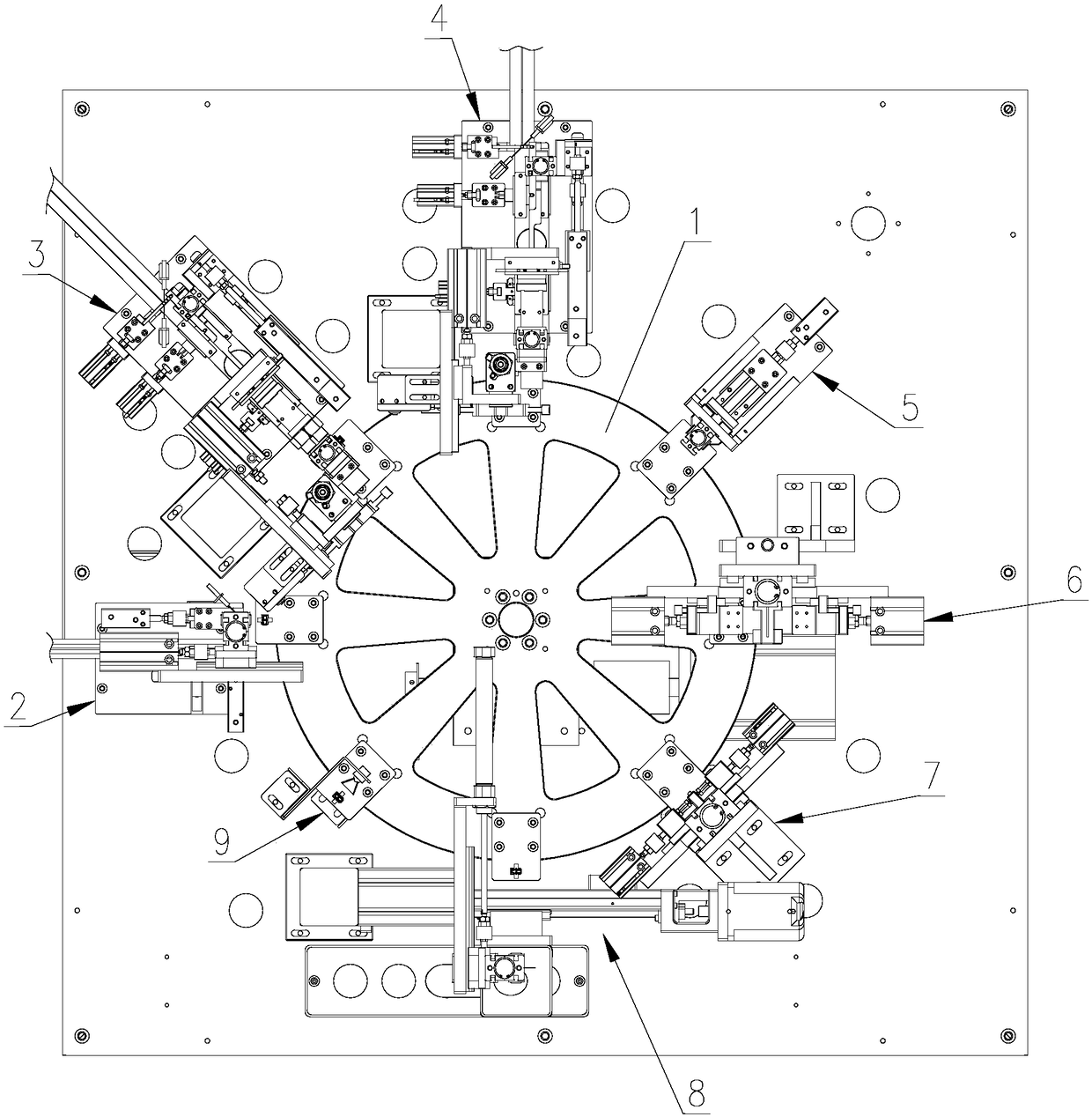

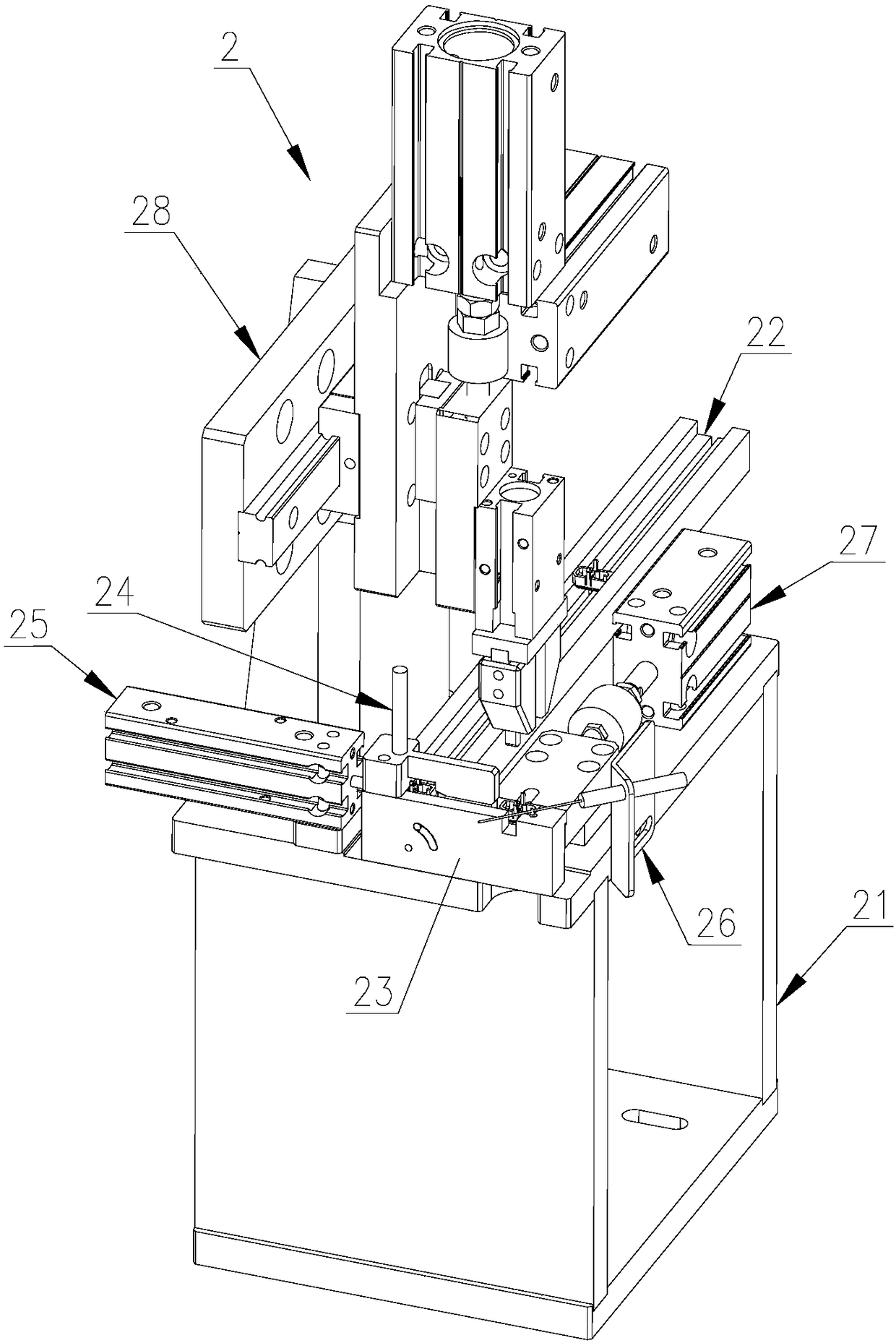

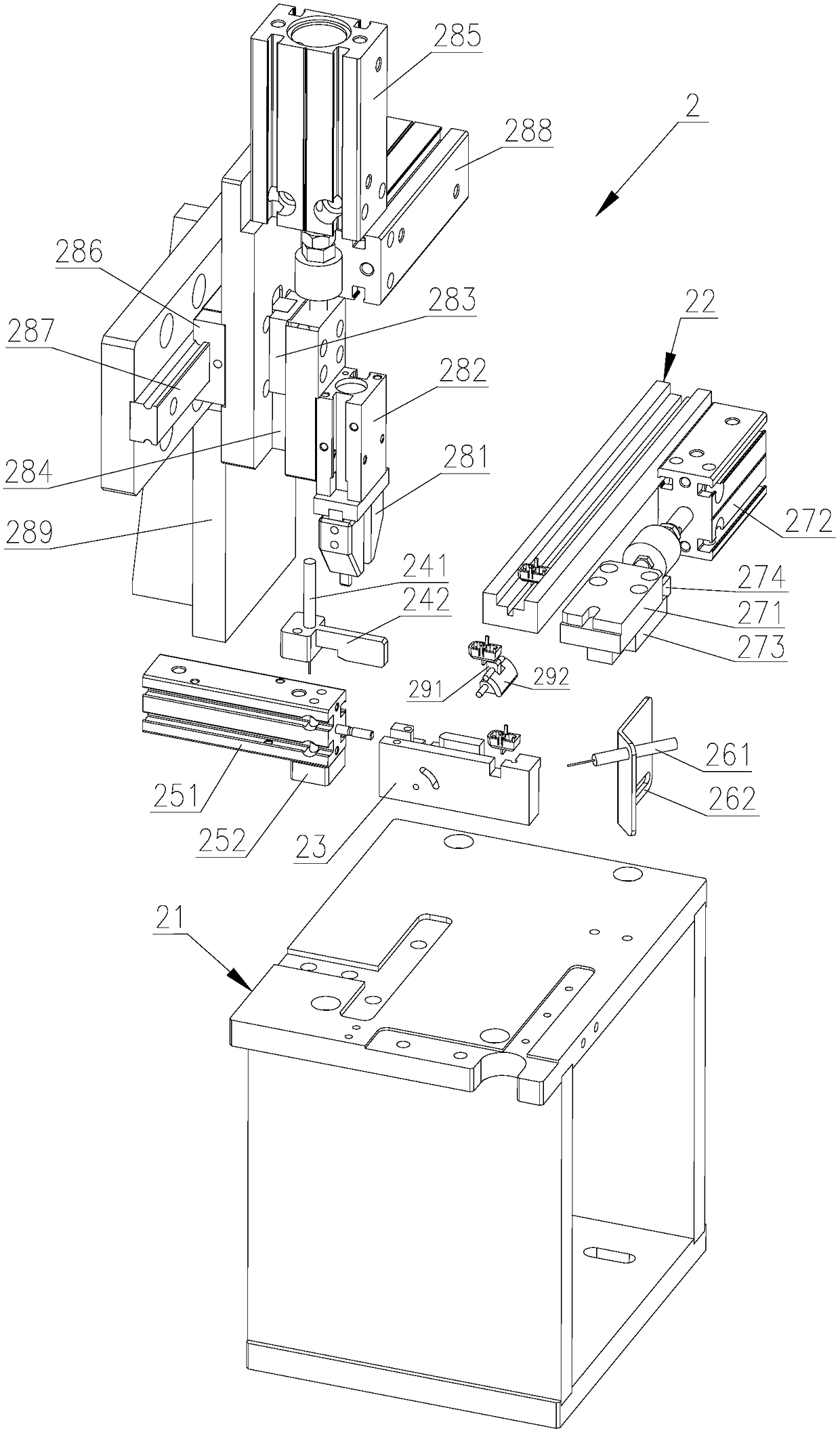

[0018] like Figure 1 to Figure 19 As shown, a fully automatic assembly equipment for photoelectric switches, which includes a frame and a workbench arranged on the frame, a turntable 1 is arranged on the workbench, and a carrier for placing plastic shells is arranged on the turntable 1, the turntable 1 There are a total of 8 stations on the top, which are the upper plastic shell station, the upper emitting LED station, the upper receiving LED station, the shaping station, the pin cutting station, the functional testing station, the finished product discharge station, the loading station There is an emptying station, and a carrier is installed on each station; the turntable 1 is driven by a servo motor-driven cam divider. On the workbench at the corresponding positions of the 8 stations on the outer periphery of the turntable 1, an upper plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com