Waterproof shoe cover and processing method thereof

A waterproof shoe cover and processing method technology, which is applied to footwear, footwear, and other household appliances, can solve the problems of restricting product categories and upgrading, and low work efficiency, so as to improve product quality, reduce energy consumption, and enrich product categories. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A waterproof shoe cover, including a shoe upper made of waterproof fabric, the sole is directly injection-molded on the upper edge by an injection molding machine, and the formed shoe sole and shoe upper are firmly bonded by using the temperature and pressure of the melt during injection molding Together.

[0041] The processing method of the waterproof shoe cover comprises the following steps:

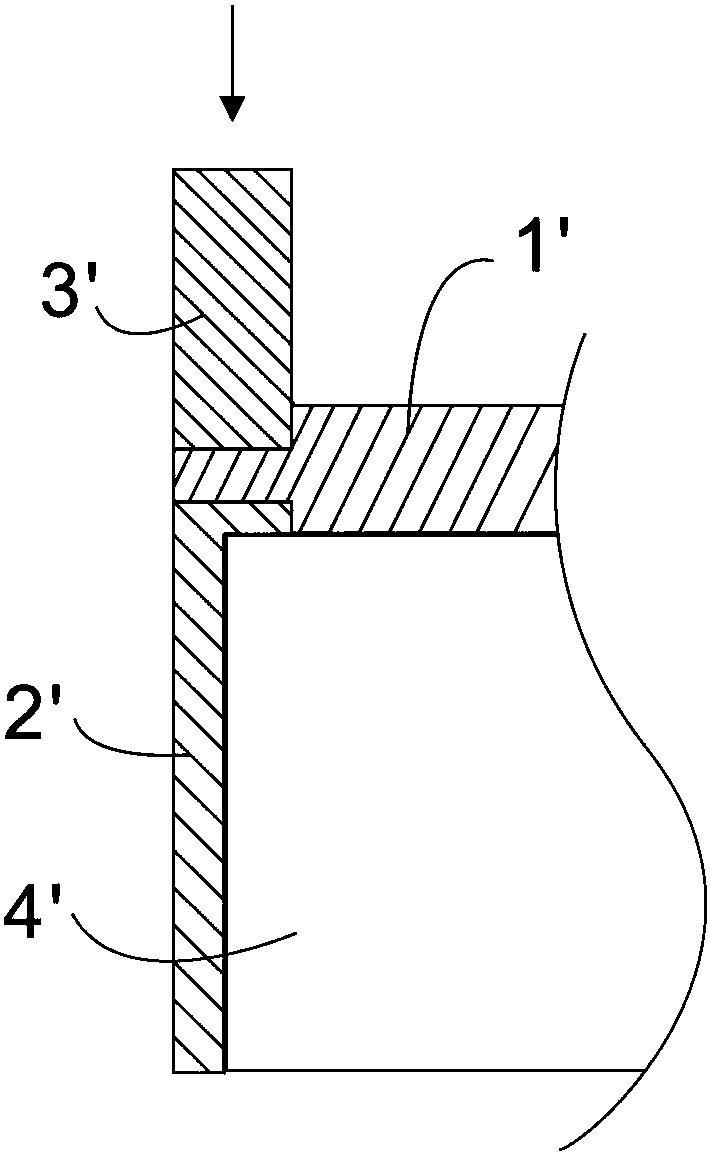

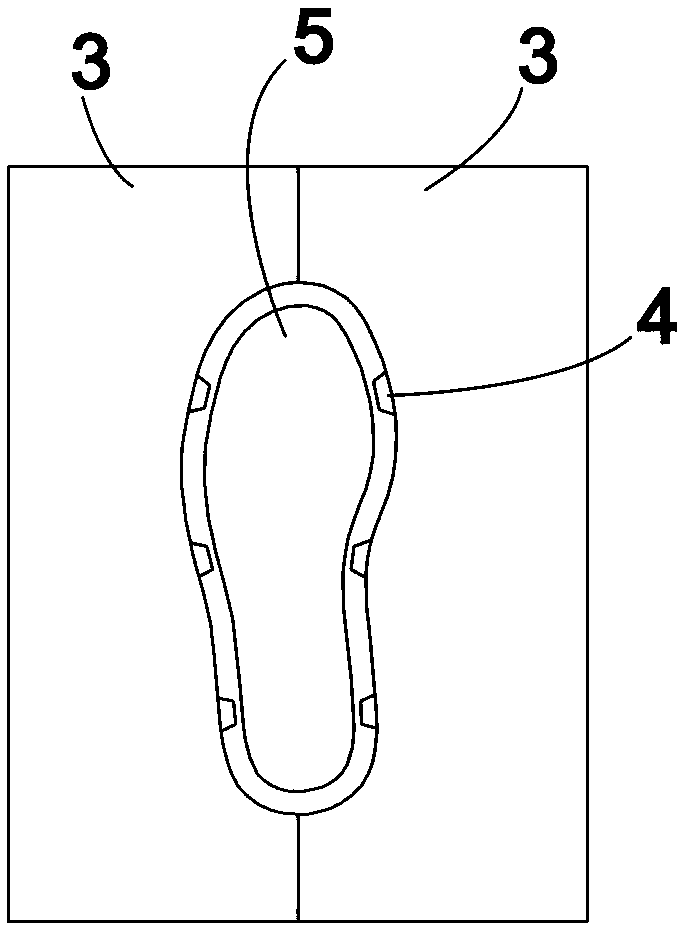

[0042] S1. Set the finished upper on the inner mold of the injection mold, and close the outer mold; the inner mold is the inner core of the sole injection mold (ie, the mold core) that matches the upper; the inner mold and the closed outer mold form the sole together shaped injection cavity;

[0043] S2. The mold locking mechanism of the injection molding machine locks the inner mold and the outer mold of S1, and then injection molding, using the temperature and pressure of the melt glue during injection molding to firmly bond the molded sole and upper together.

[0044] In ...

Embodiment 2

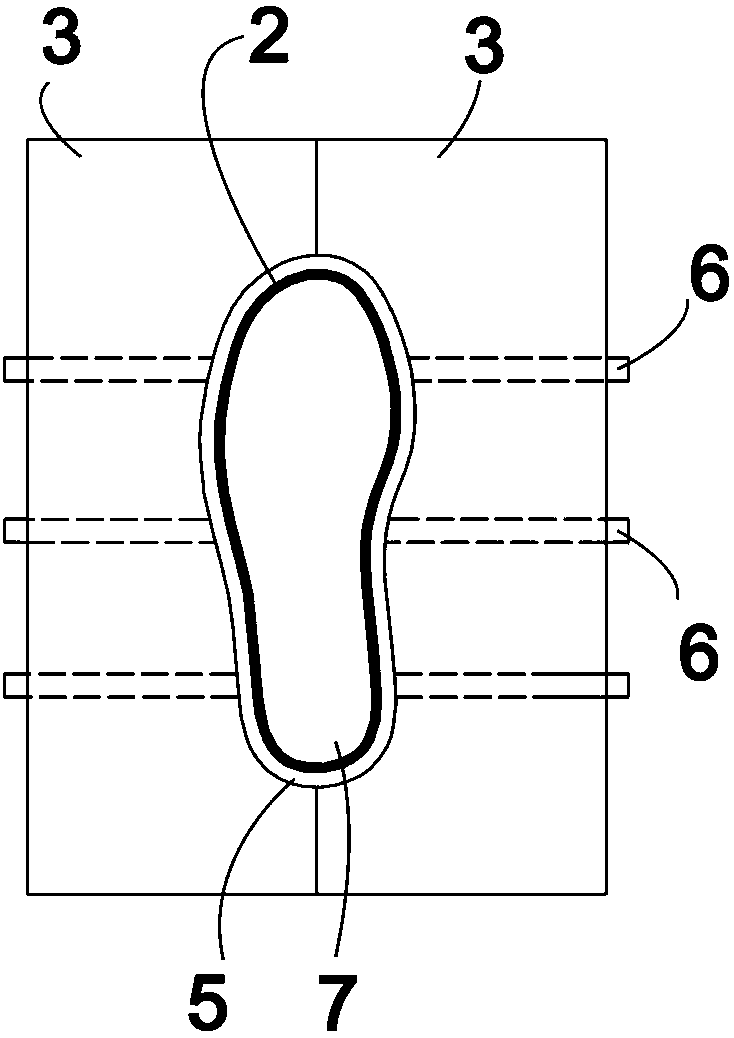

[0047] Referring to Example 1, the difference from Example 1 is that the pressing boss 4 of Example 1 is changed to a pressing pin 6, and injection molding is performed twice, as image 3 and Figure 4 shown. During one injection molding, the pressing pin 6 is pressed into the cavity, forcing the vamp 2 to be close to the mold core 7. After the injection molding is completed, the pressing pin 6 returns to its original position, and the gap of the pressing pin is filled by the secondary injection molding. image 3 and Figure 4 6 injection molding ports 8 are shown schematically, Figure 4 The middle arrow indicates the injection direction.

Embodiment 3

[0049] Referring to Example 2, the difference from Example 2 is that Example 2 is changed to two-color injection molding, and plastics of different colors are used to fill the space between the pressing pins, and the mold is designed at the same time, such as the bottom mold is a two-color bottom mold, so that the sole presents a two-color effect , Greatly enhance the taste and grade of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com