Spring cushion and shock absorber support mounting structure assembly and automobile

A technology of installation structure and shock-absorbing pad, applied in elastic suspension, vehicle spring, suspension, etc., can solve problems such as cracking and wear of spring shock-absorbing pad, so as to reduce the shock-absorbing effect, avoid motion wear, and avoid relative motion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

[0026] The embodiment of the present invention aims at the prior art when the car is running, the spring will not only receive the vertical force, but also the lateral force. This lateral force causes the spring shock pad to rotate relative to the shock absorber bracket, resulting in The spring damping pad is worn and cracked, which affects the problem of use. A spring damping pad and damper bracket mounting structure assembly and automobile are provided, thereby reducing the risk of abnormal wear of the spring damping pad and improving the performance of the spring damping pad. Service life.

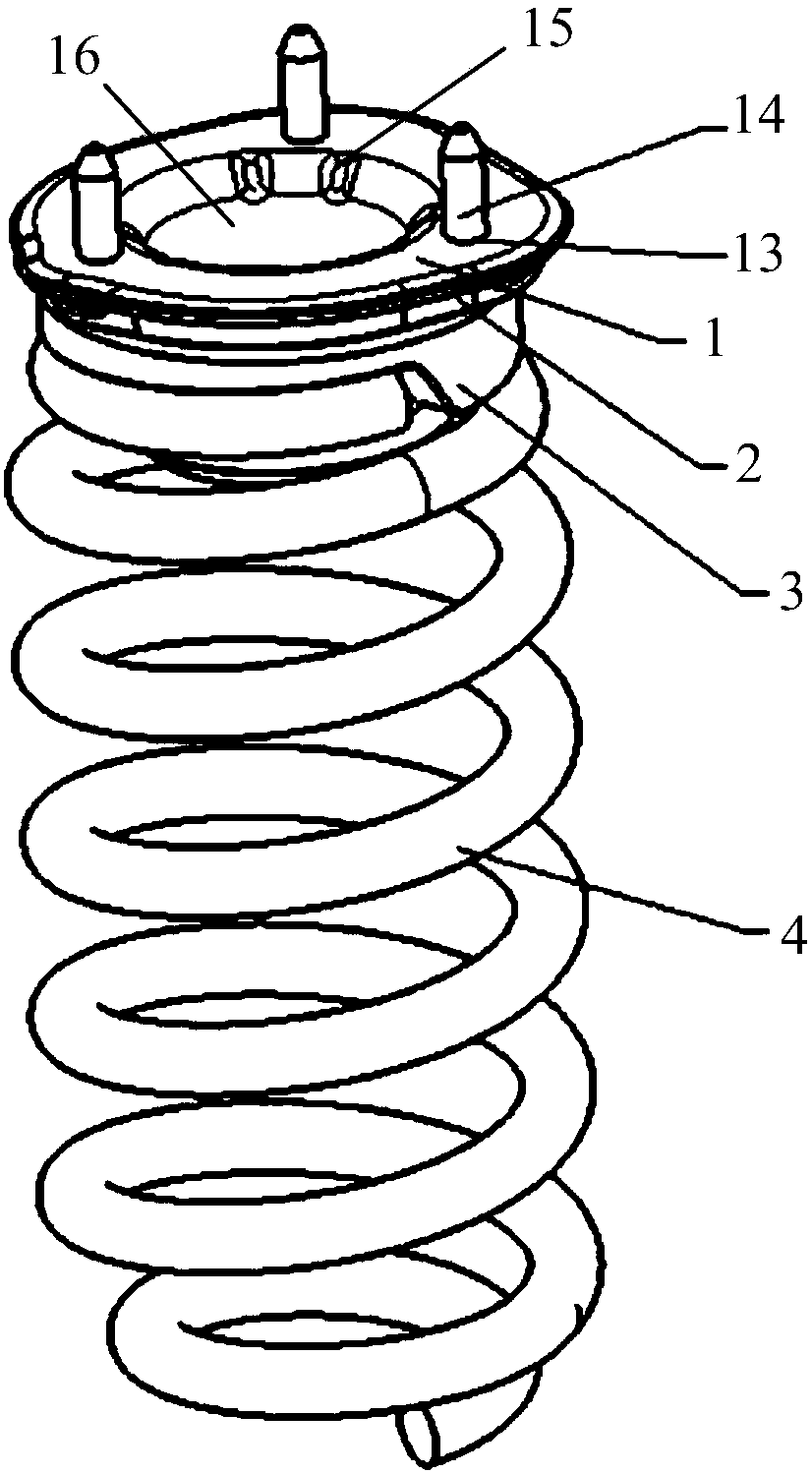

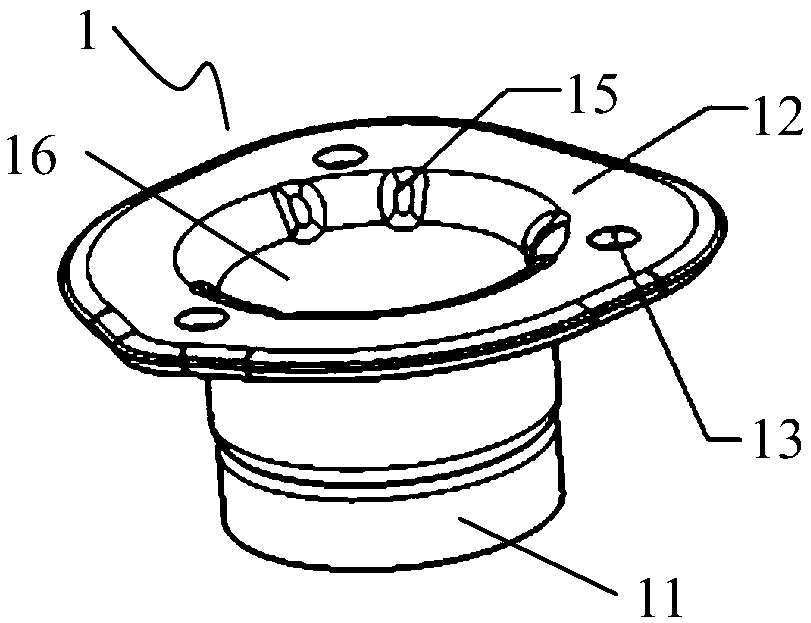

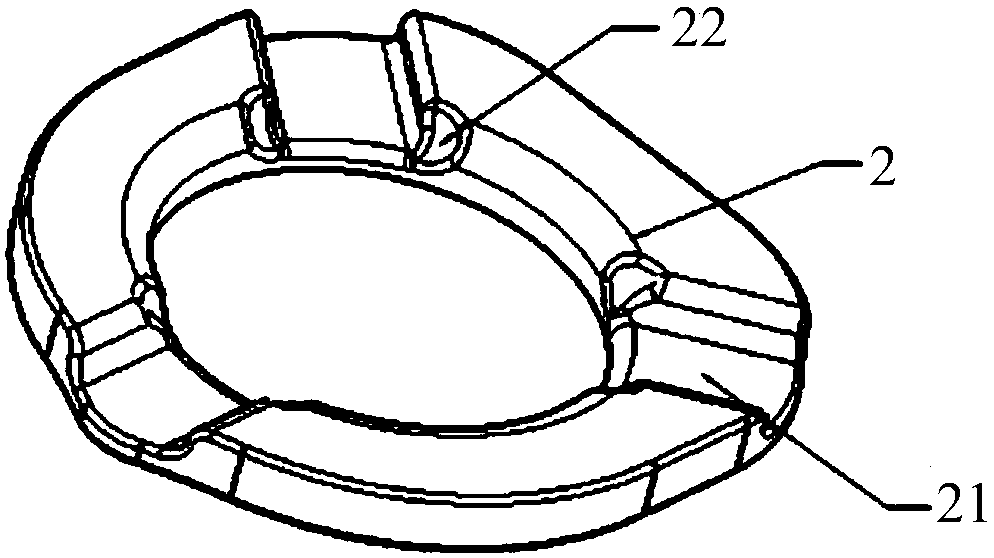

[0027] Such as Figure 1-Figure 4 As shown, an embodiment of the present invention provides a spring damping pad and a damper bracket mounting str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com