A filter pipe mesh plate grille

A filter pipe network and filter pipe technology, applied in the direction of filtration and separation, fixed filter element filter, separation method, etc., can solve the problems of reducing grid resistance coefficient, frequent equipment failures, performance degradation, etc. surface, improve the service life, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

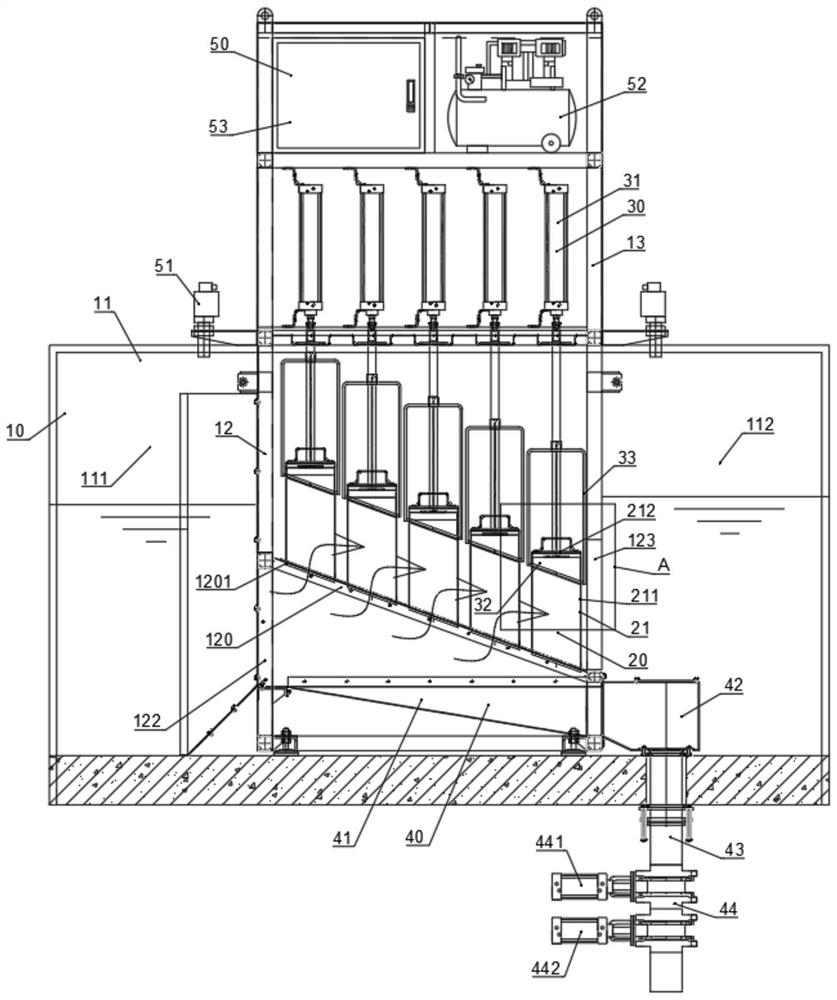

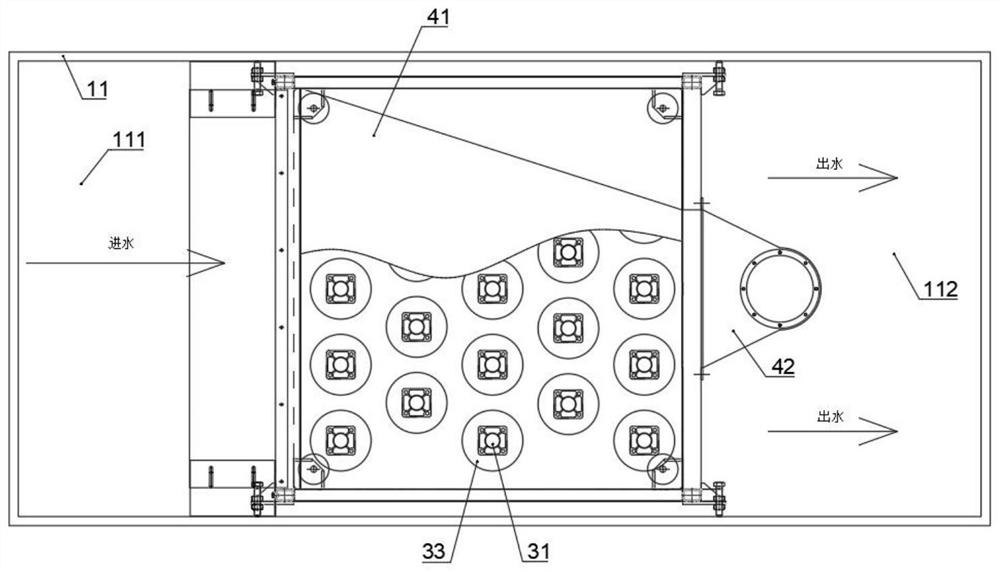

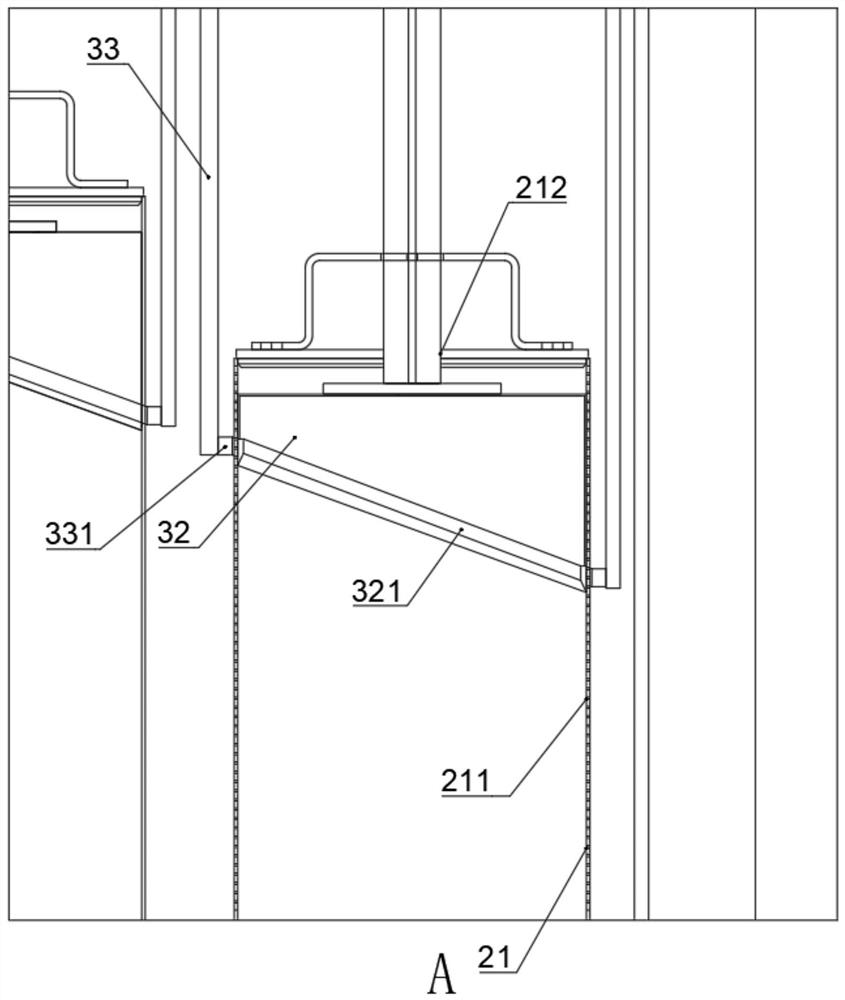

[0055] A filter pipe mesh plate grid, such as figure 1 As shown, it includes a frame 10, a filter tube assembly 20, a slag cleaning assembly 30, a slag discharge assembly 40 and a monitoring and control unit 50;

[0056] like figure 1 As shown, the rack 10 includes a total accommodating shell 11, a filter shell 12 is fixed in the overall accommodating shell 11, and a water-passing inclined plate 120 is fixed in the filter shell 12, and the water-passing inclined plate 120 has a a plurality of water through holes 1201 penetrating up and down;

[0057] The included angle between the water-passing inclined plate 120 and the horizontal is 20°;

[0058] like figure 1 As shown, the side of the sloping plate 120 close to the water inlet silo 111 is higher than the side close to the water outlet silo 112;

[0059] like figure 1 As shown, a water inlet silo 111 is formed between the left side wall of the filter shell 12 and the left inner wall of the total accommodating shell 11 ,...

Embodiment 2

[0076] The difference from Embodiment 1 is that the included angle between the water-passing inclined plate 120 and the horizontal is 50°;

[0077] The inclination angle of the bottom of the slag discharge accommodating shell 41 is 30°;

[0078] The slag discharge pipe 43 at the connection of the slag discharge pneumatic valve 442 has a certain angle with the vertical direction, and the angle range is 90°;

[0079] The filtered water outlet hole 211 is a strip through hole;

[0080] The controller 53 adopts a single chip controller.

Embodiment 3

[0082] The difference from Embodiment 1 is that the angle between the water-passing inclined plate 120 and the horizontal is 30°;

[0083] The inclination angle of the bottom of the slag discharge accommodating shell 41 is 20°;

[0084]The slag discharge pipe 43 at the connection of the slag discharge pneumatic valve 442 has a certain angle with the vertical direction, and the angle range is 45°;

[0085] The filtered water outlet hole 211 is a round hole-shaped through hole;

[0086] Described controller 53 adopts PLC controller;

[0087] In the actual application process of the present invention, the water body to be treated enters from the water inlet bin 111 , and the water body to be treated in the water inlet bin 111 enters the filter shell 12 through the water inlet port 122 at the The part below the water-passing inclined plate 120, and then the water to be treated enters the filter tube 21 through the water-passing hole 1201. After the filter tube 21 filters the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com