A steel plate shear wall with holes and oblique seams and its application

A steel plate shear wall and oblique joint technology, applied to walls, buildings, building components, etc., can solve the problems of different stress mechanisms and the inability to effectively limit the buckling of steel plates under compression, and achieve adjustable design parameters, ductility and energy consumption. The effect of good ability and clear mechanism of lateral force resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

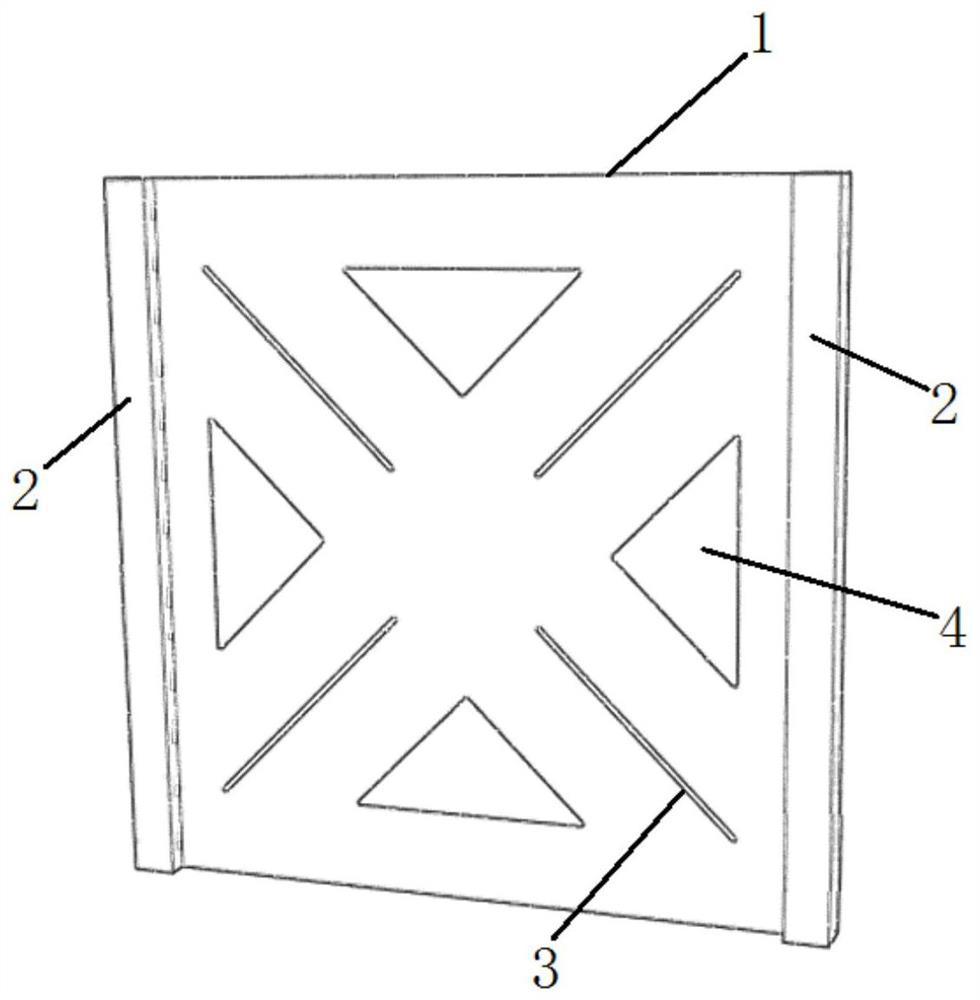

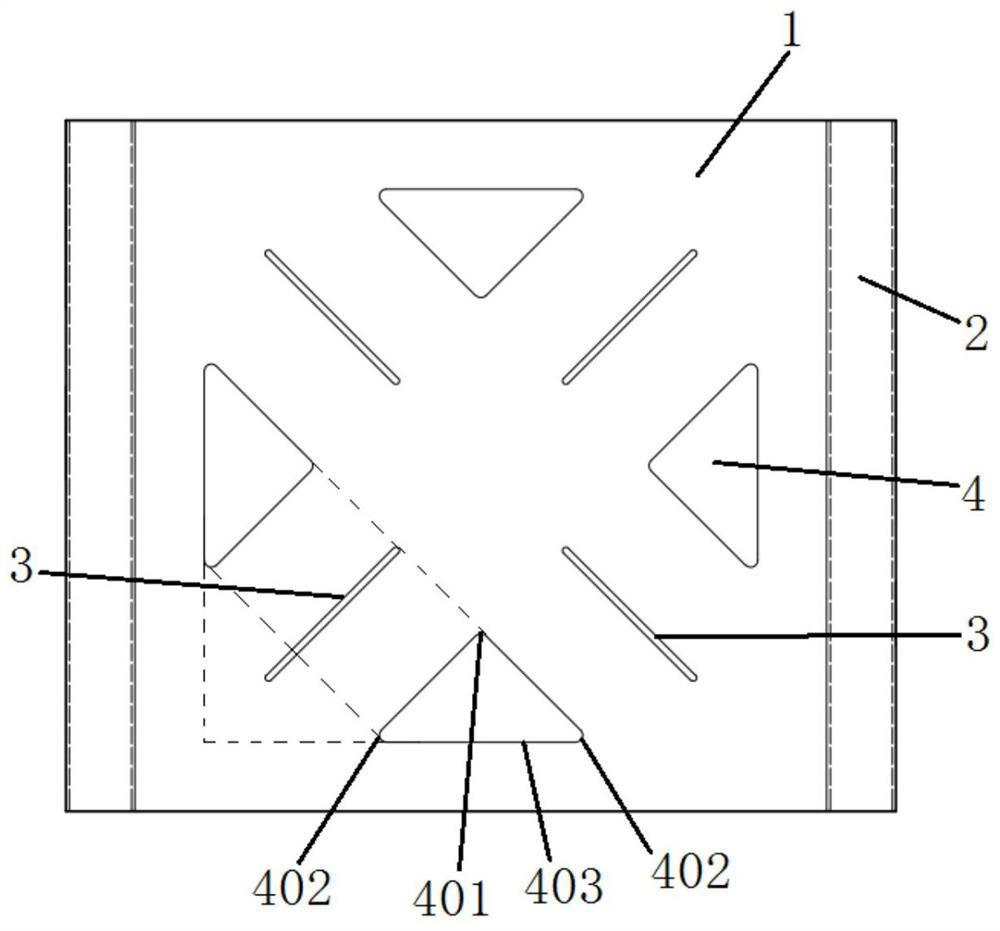

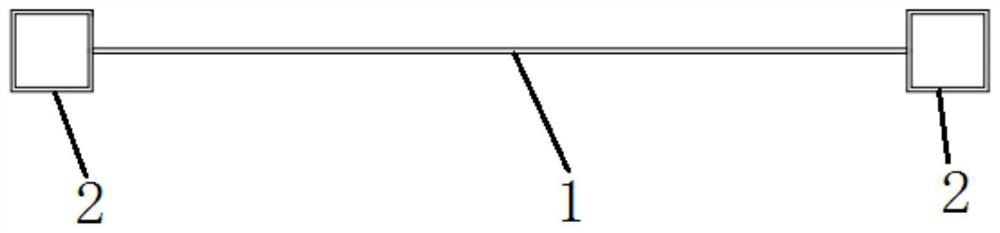

[0035] Such as figure 1 , figure 2 , image 3 A steel plate shear wall with openings and oblique seams is shown. The steel plate shear wall includes a thin steel plate 1 and a pair of edge stiffeners 2 arranged side by side on both sides of the thin steel plate 1. Each diagonal of the thin steel plate 1 A pair of diagonal slits 3 are symmetrically opened on the line, and four triangular holes 4 are opened on the thin steel plate 1 , and each triangular hole 4 is located between two adjacent diagonal slits 3 .

[0036] Wherein, the thin steel plate 1 is square, and the diagonal slits 3 are provided on the diagonal along the length direction of the diagonal. The triangular hole 4 is an isosceles triangle. The isosceles triangle can choose a right-angled isosceles triangle (such as Figure 4 shown) or a non-right isosceles triangle (such as Figure 5 shown).

[0037] The triangular hole 4 includes a top corner vertex 401 and a pair of bottom corner vertices 402. Between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com