A high-efficiency socket pipe interface installation device

A pipeline interface and installation device technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as high man-machine cost, difficult quality control, and pipeline damage, so as to reduce labor costs, The effect of saving installation time and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

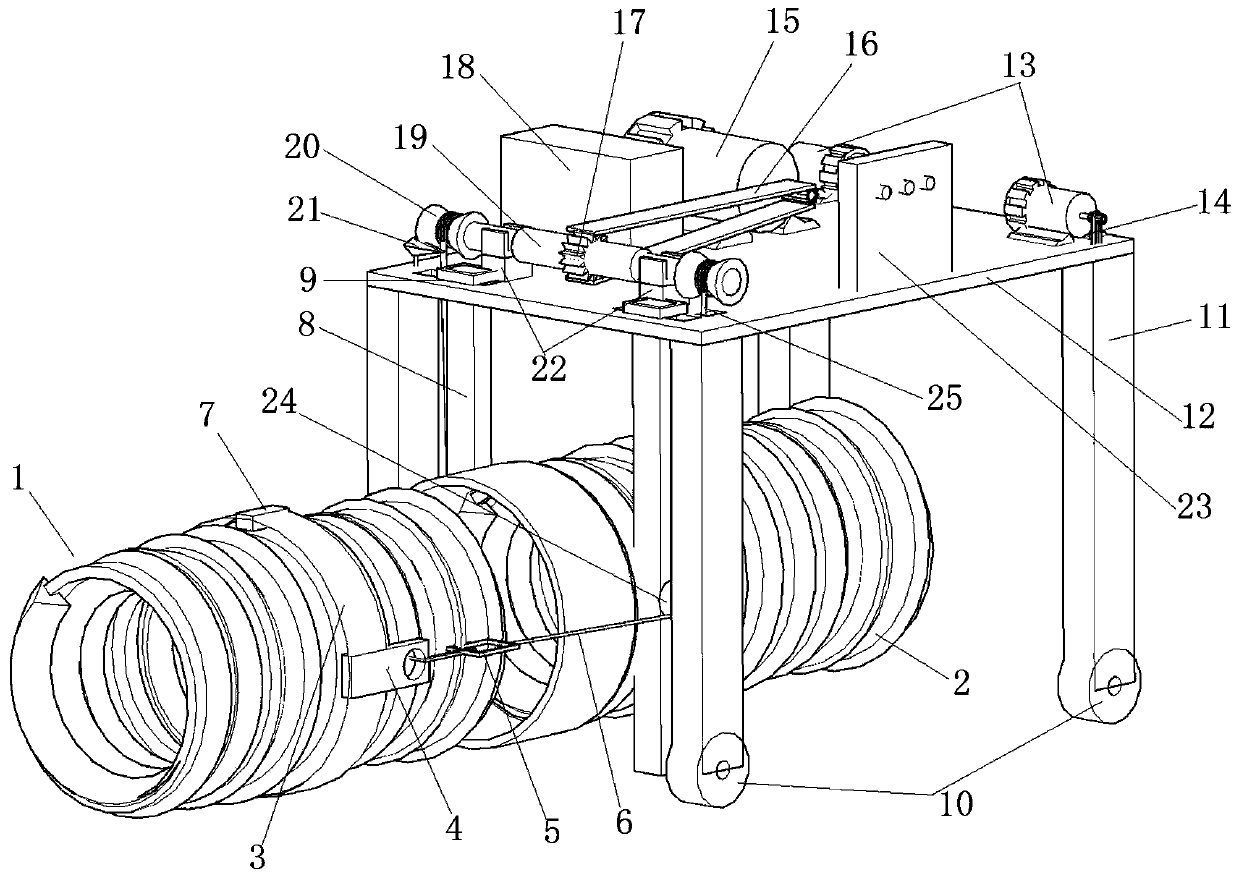

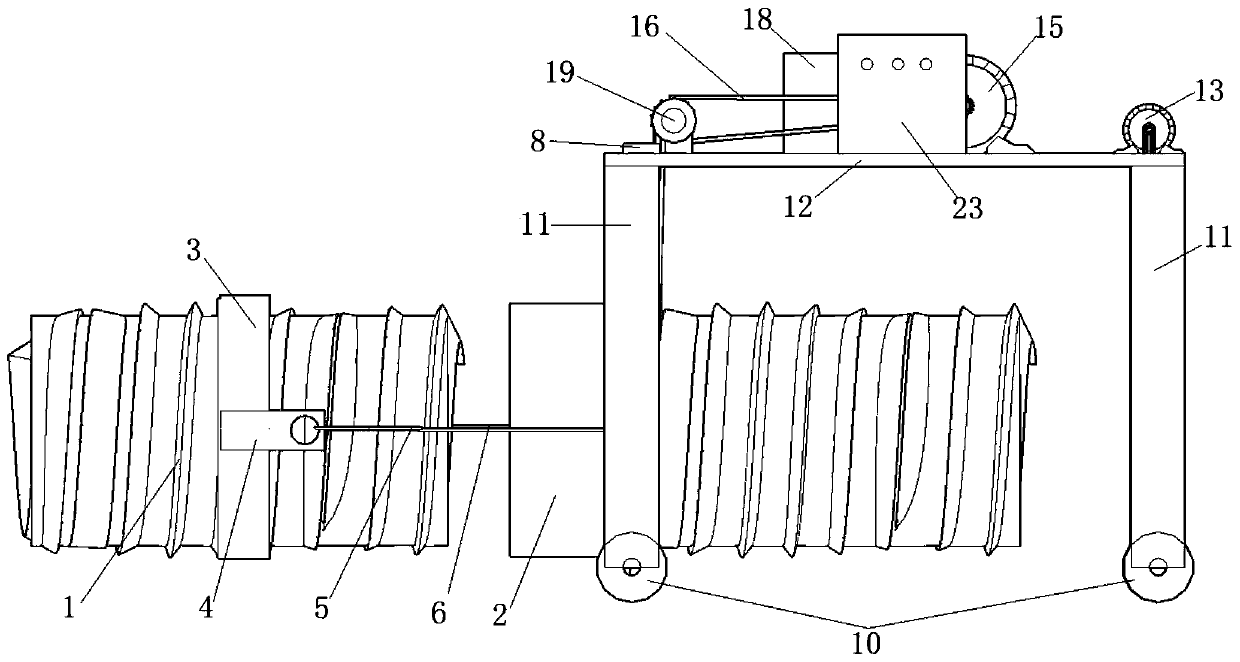

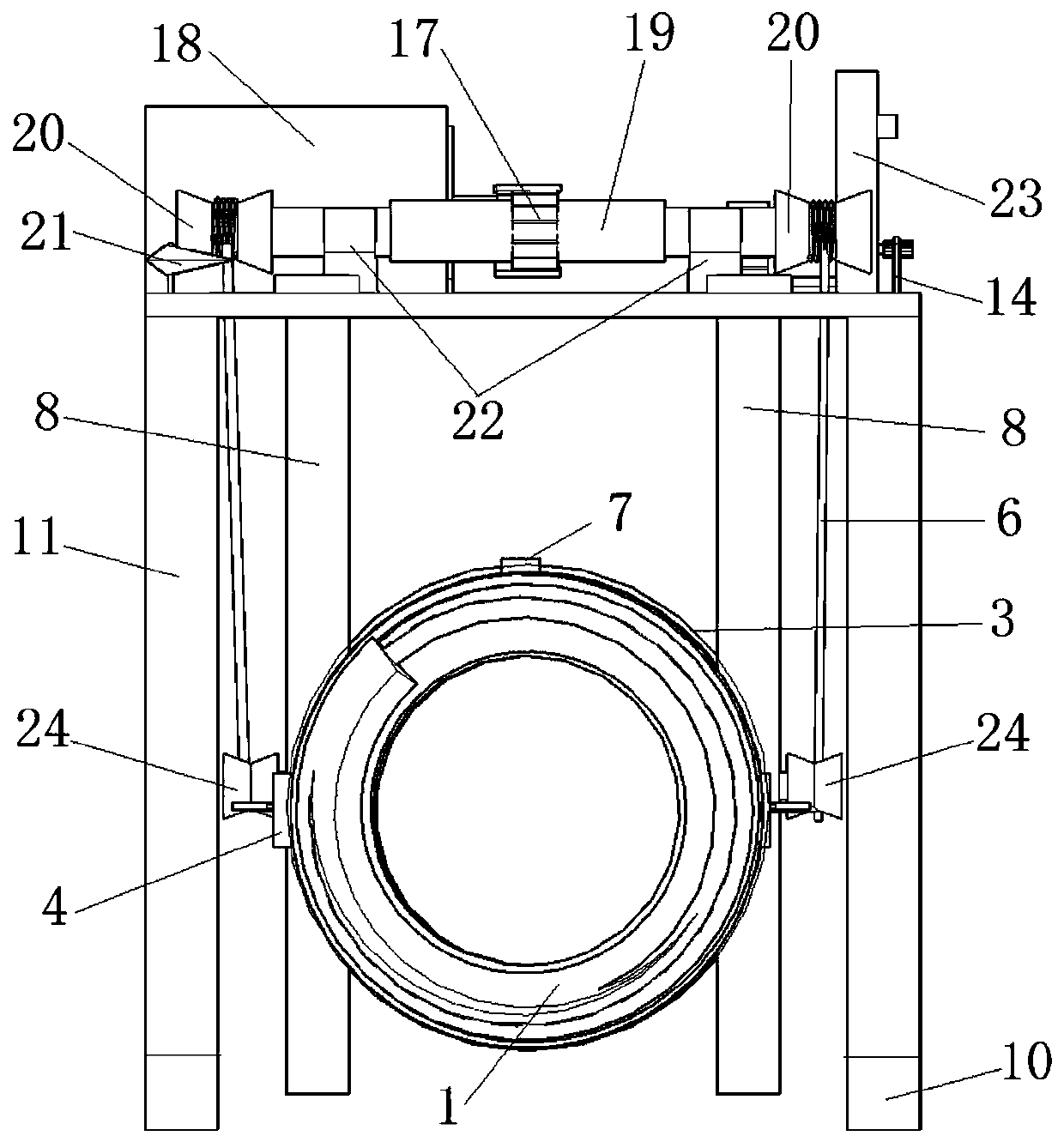

[0064] The efficient socket pipe interface installation device of this embodiment includes a device moving system that drives the entire device to move, and is composed of an auxiliary motor 13, a roller transmission chain 14 and a roller 10; the operation controller panel 23 moves the device to the pipe interface. Specify the location. And the transmission system that is installed on the device platform 12 is made up of main motor 15, power transmission shaft 19 and storage battery 18 etc., this system pulls steel strand 6 contraction under the drive of main motor 15, produces pulling force to pipeline socket 1. Transmission shaft 19 is installed on the fixed support 22 that is welded on platform 12, and transmission shaft 19 two ends are equipped with reel 20 and are used for shrinking steel strand 6. Wire reel 20 lower sides open wire hole 25, and steel strand 6 passes through wire hole 25, changes direction by the pulley 24 on socket fixed rod 8.

[0065]The device is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com