Automatic feeding heating stove capable of combusting multiple kinds of fuel

A technology for automatic feeding and heating stoves, which is applied to solid heating fuels, stoves/stoves with hot water devices, household stoves/stoves, etc. It can solve problems such as low combustion utilization, coking of fuel, and inaccurate feeding, and achieve Reduce workload, prevent crossfire, and feed accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment:

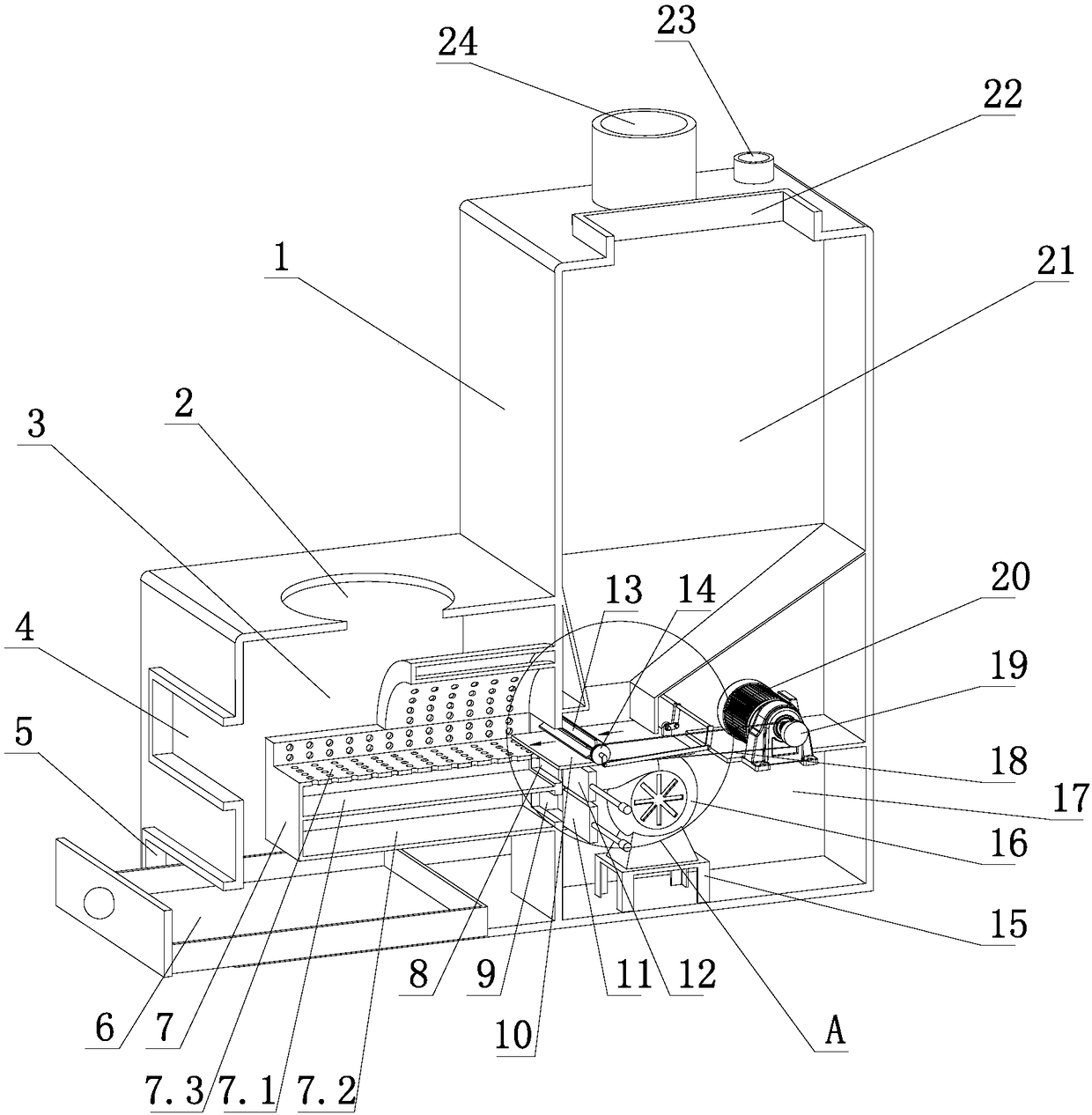

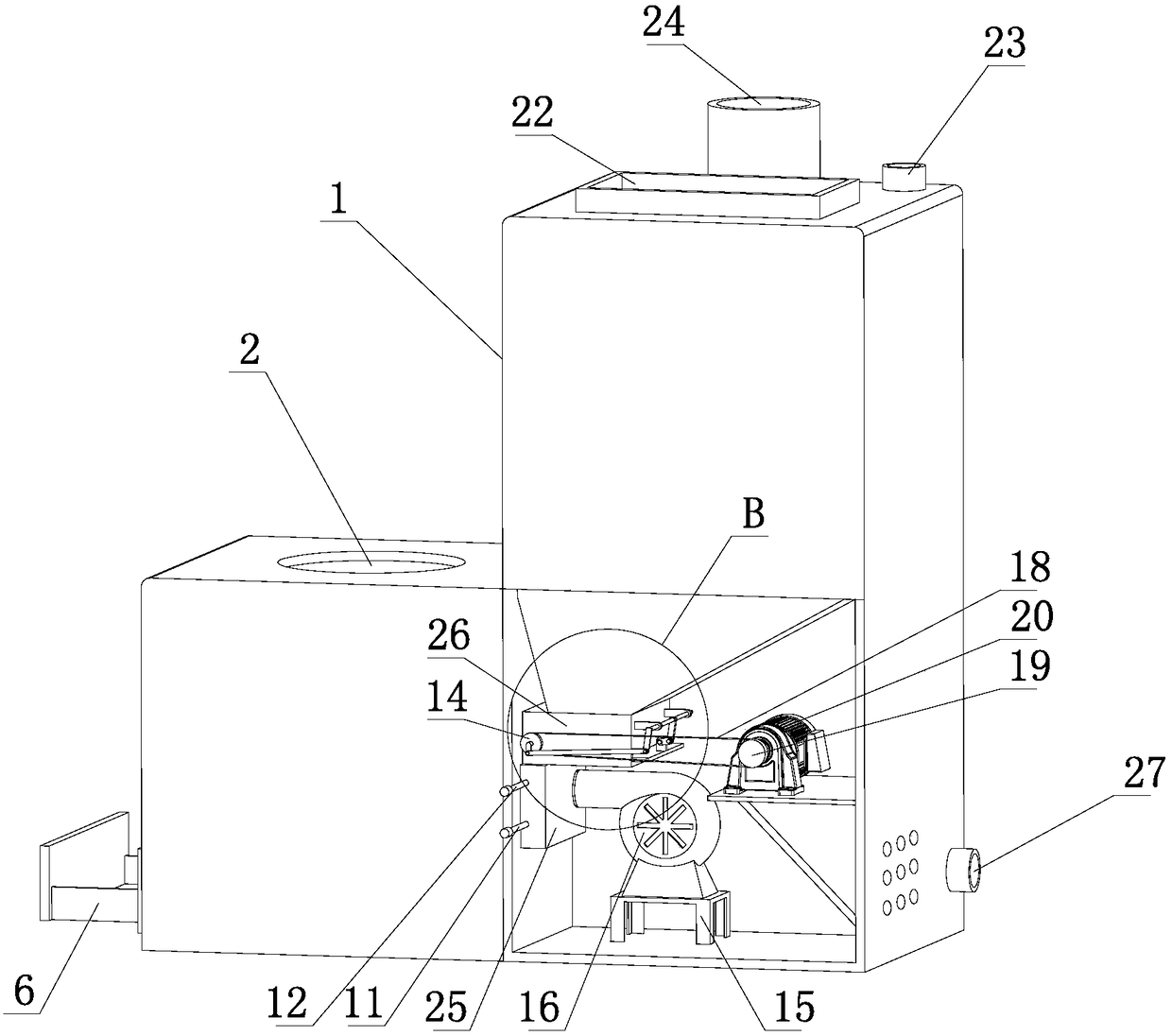

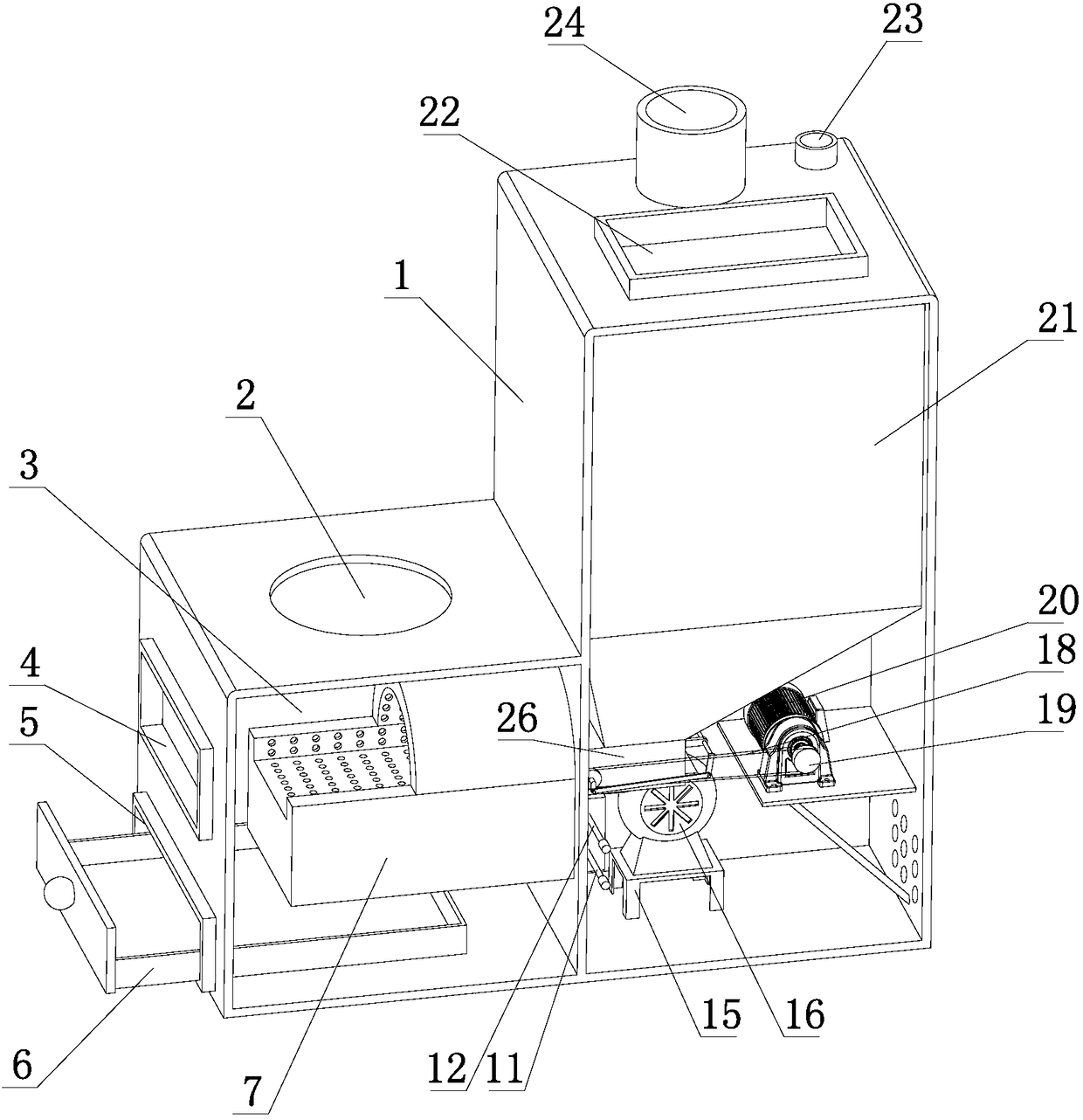

[0024] like Figure 1-7 As shown, the automatic feeding heating furnace capable of burning multiple fuels of the present invention includes a box body 1 with a water tank inside, and a water outlet 23 and a water return port 27 communicating with the water tank on the box body 1 . The box body 1 is provided with a cooking port 2, an ash cleaning port 4, an ash outlet 5 and a smoke outlet 24, the ash outlet 5 is provided with an ash bucket 6, and the box body 1 is provided with a combustion chamber 3 and a material box 21 And the equipment room 17, feed inlet 22 is provided on the top of feed box 21, combustion device 7 is arranged in the combustion chamber 3, combustion device 7 is divided into three layers, the top layer is the combustion chamber 7.3, the middle layer is the first air supply channel 7.1, The bottom layer is the second air supply channel 7.2, and the bottom, side an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com