Multi-angle fillet weld residual stress test centring device

A residual stress and centering device technology, which is applied in the direction of measuring devices, workpiece clamping devices, force/torque/work measuring instruments, etc., can solve the problem of large residual stress measurement errors in fillet welds, difficulty in tilting and fixing devices, and problems in fillet welds. Unable to measure and other problems, to achieve the effect of high work efficiency, small error, and high centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

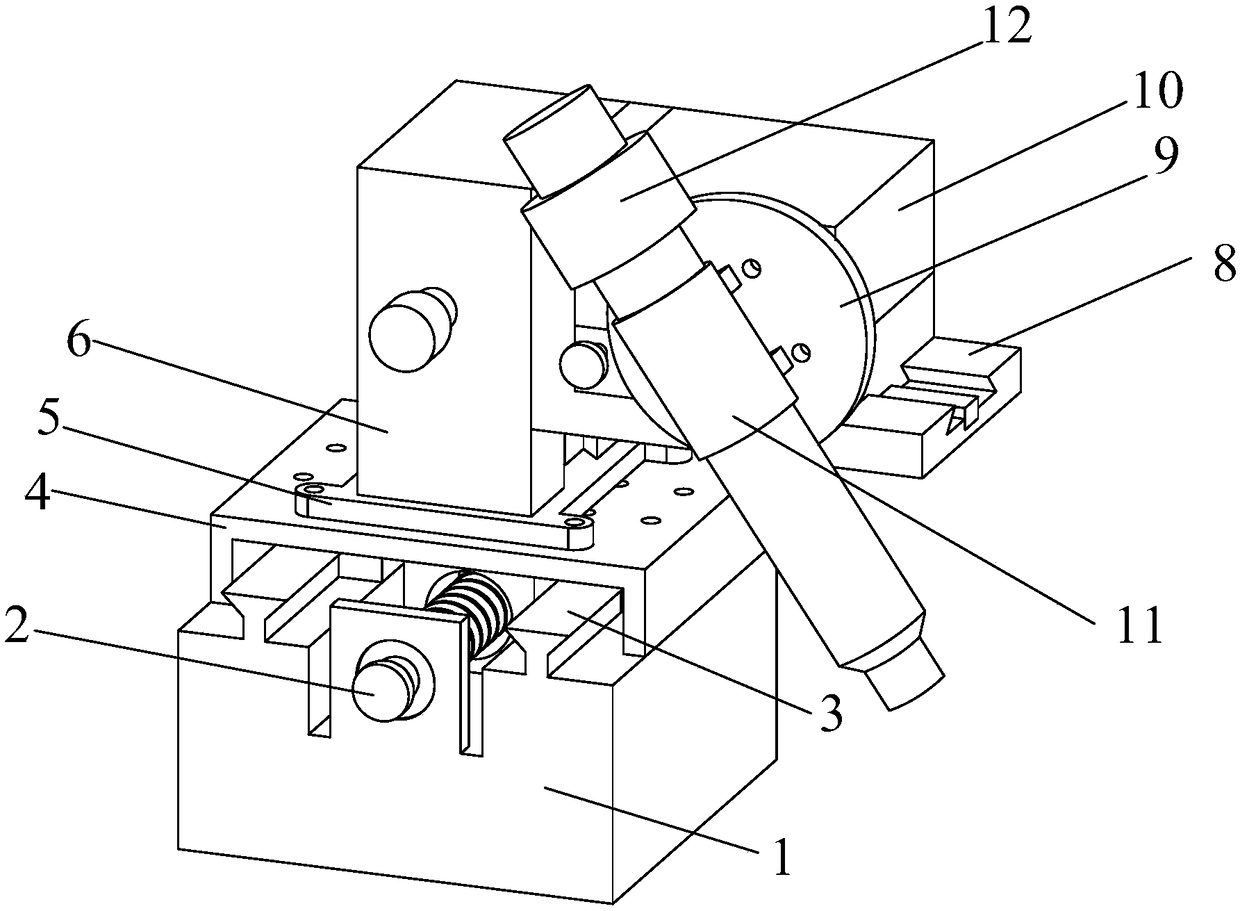

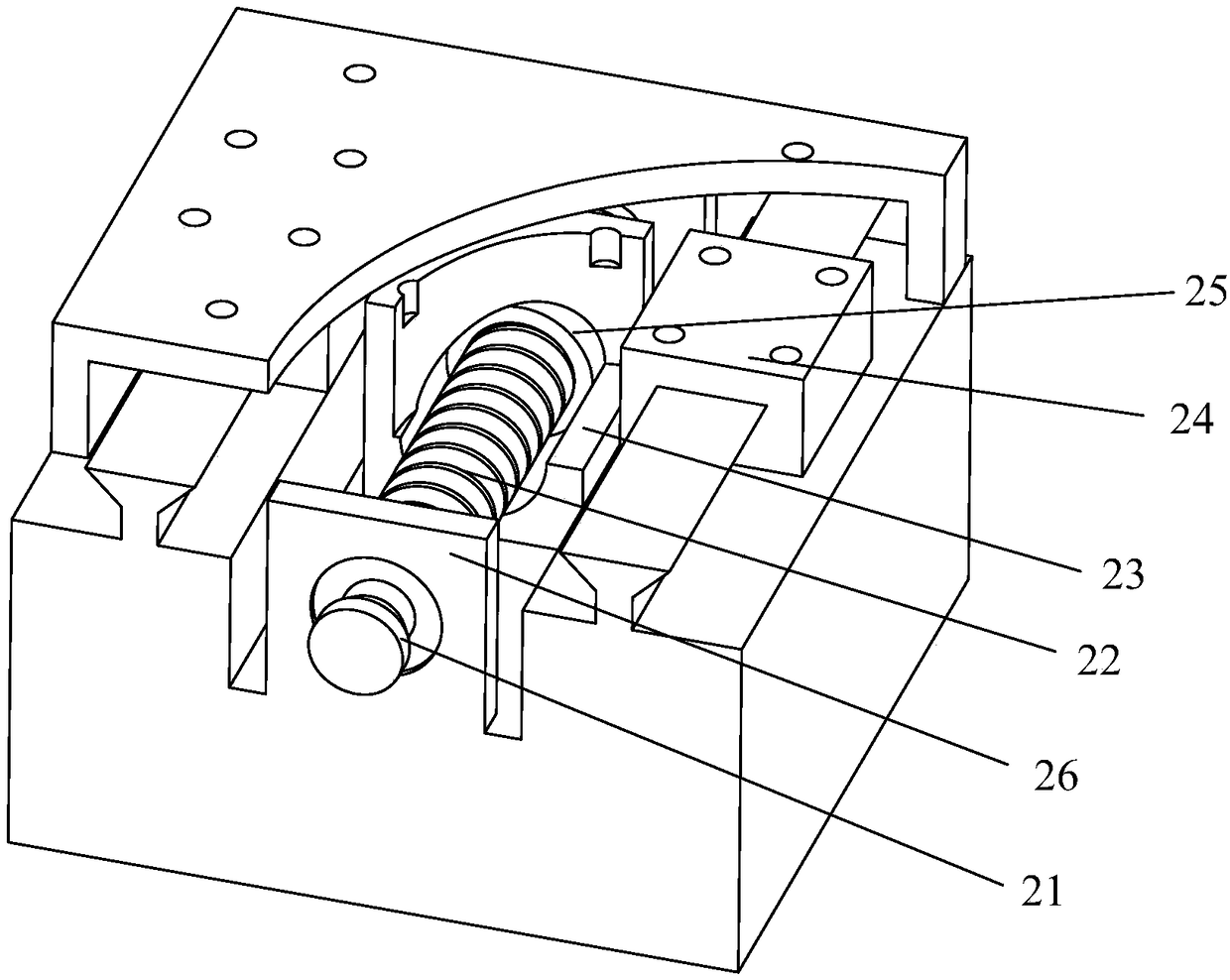

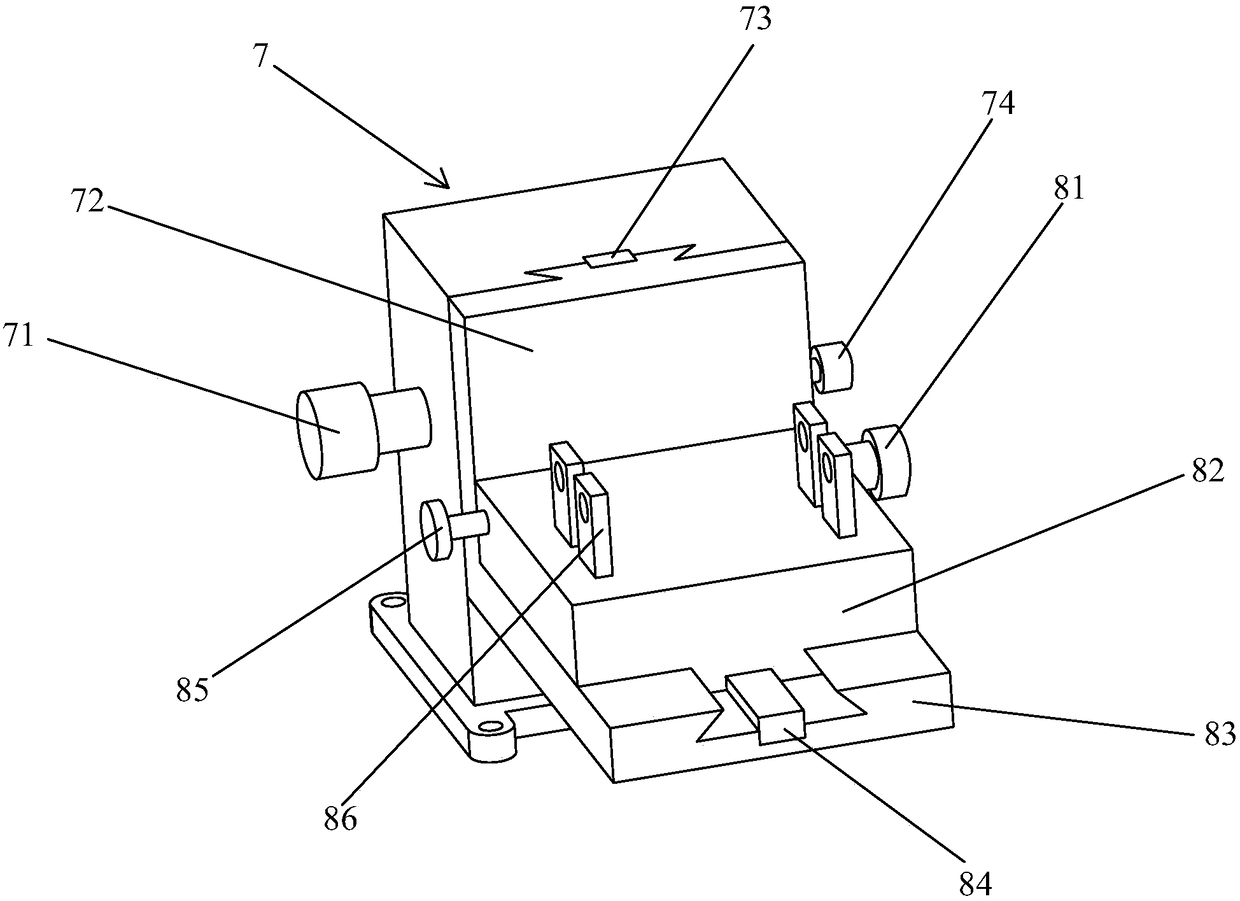

[0021] Such as figure 1 As shown, the impact indentation method measuring and centering device that can realize the residual stress test of multi-angle fillet welds includes a plane base 1, a longitudinal level adjustment mechanism 2, a vertical transmission mechanism 7, a transverse level adjustment mechanism 8 and an angle rotation adjustment mechanism 9. The longitudinal horizontal adjustment mechanism 2 is fixed on the top of the plane base 1, and the longitudinal horizontal adjustment mechanism 2 adopts ball screw adjustment to realize the longitudinal horizontal movement of the longitudinal mobile platform 4. In order to ensure the stability of the longitudinal mobile platform, the longitudinal mobile platform 4 passes 24 and the slider guide rail 3 are connected with the plane base. The vertical mobile platform 4 is connected to the column 6 by connecting the chassis 5, and a vertical transmission mechanism 7 is arranged in the column 6. The vertical transmission mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com