A coaxial nozzle for electrofluid jet printing

A coaxial nozzle, electro-fluid technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problem that the nozzle structure cannot realize the adjustment of the solution flow, the relative height of the inner and outer nozzles cannot be adjusted, and the nozzle structure is difficult to process. Large and other problems, to achieve the effect of easy installation and positioning, reduce processing difficulty, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

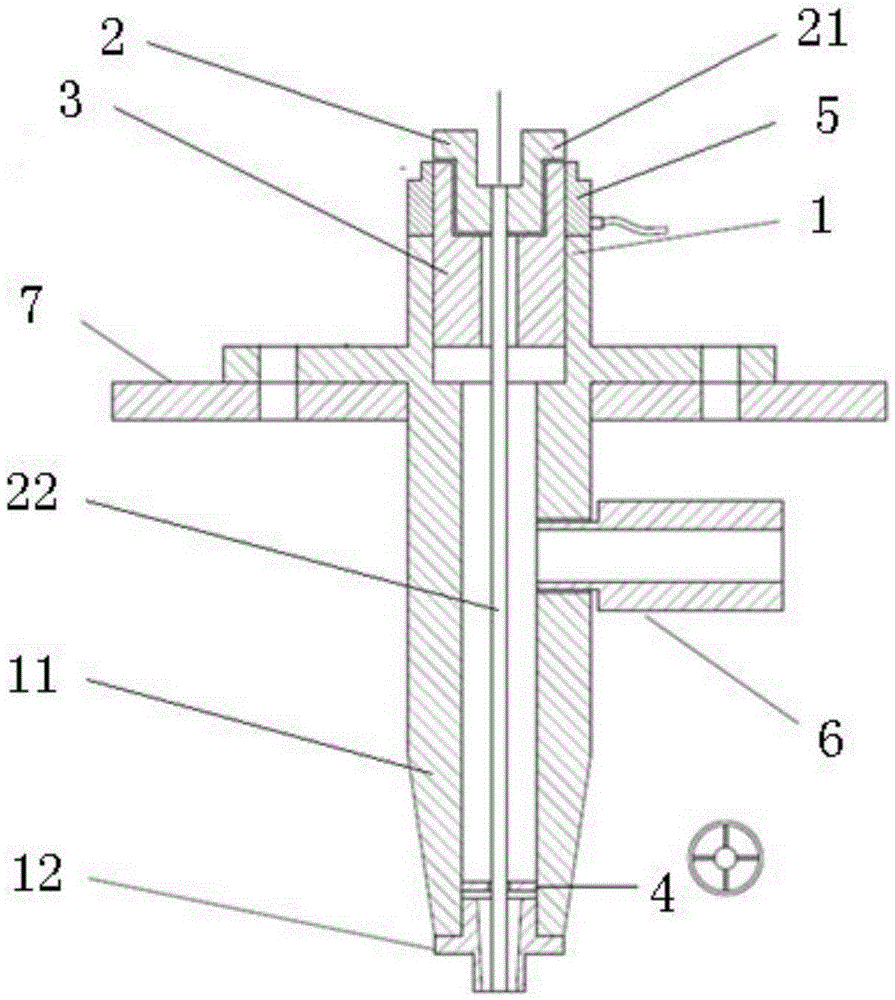

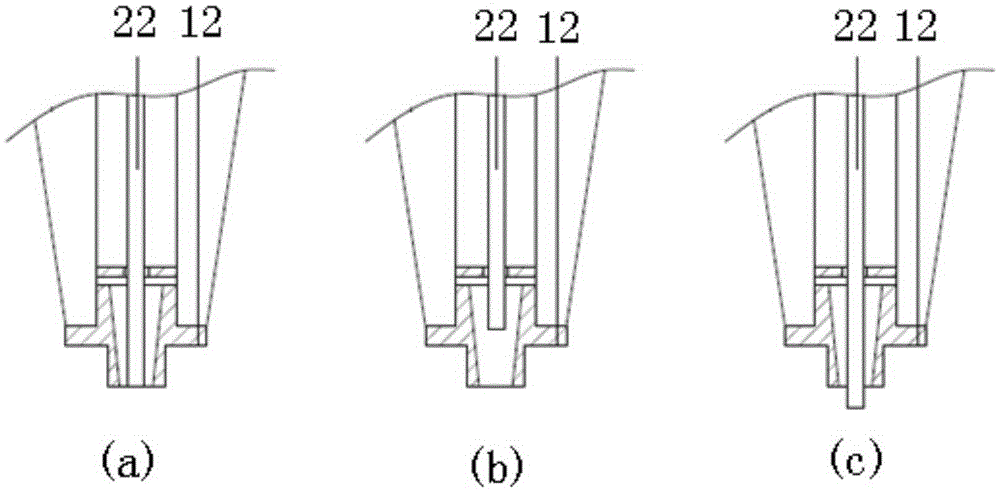

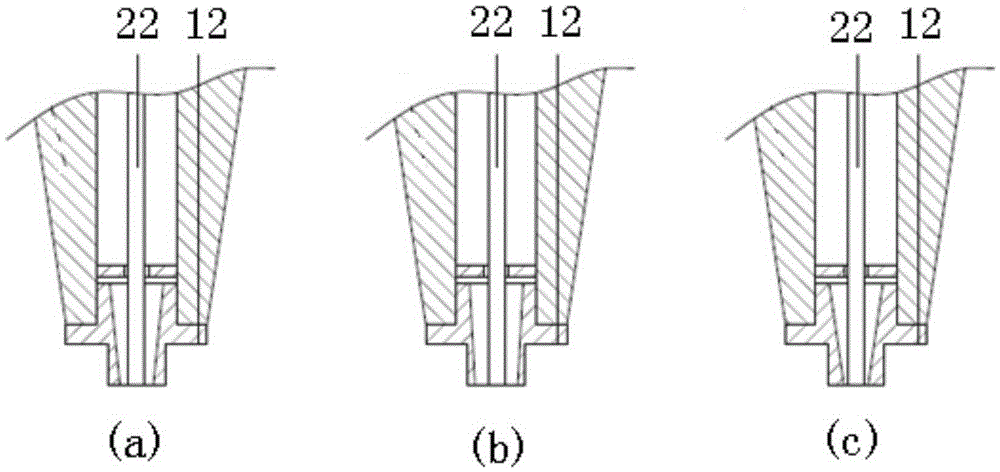

[0038] see figure 1 , the coaxial nozzle for electrofluid jet printing provided by the present invention includes an outer nozzle 1 and an inner nozzle 2 . Wherein, the outer nozzle 1 includes an outer spray barrel 11 and an outer spray head 12 sleeved on the nozzle end of the outer spray barrel 11 , and the outer spray head 12 communicates with the outer spray barrel 11 . The end of the outer spray tube 11 away from the nozzle is provided with a shaft hole with a diameter larger than the diameter of the inner tube of the outer spray tube 11, and a hollow cylindrical connecting seat 3 is sleeved in the shaft hole, and the connecting seat 3 and the outer spray tube 11 are transitionally fitted. The middle part of the connecting seat 3 is provided with an axial stepped hole, and the diameter of the stepped hole located on the outer sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com