Steel preparation method and system based on gene pool

A gene bank and gene technology, applied in the field of metallurgy, can solve the problems of lack of data and lack of utilization of data systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The principles and features of the present invention are described below, and the examples are only used to explain the present invention, but not to limit the scope of the present invention.

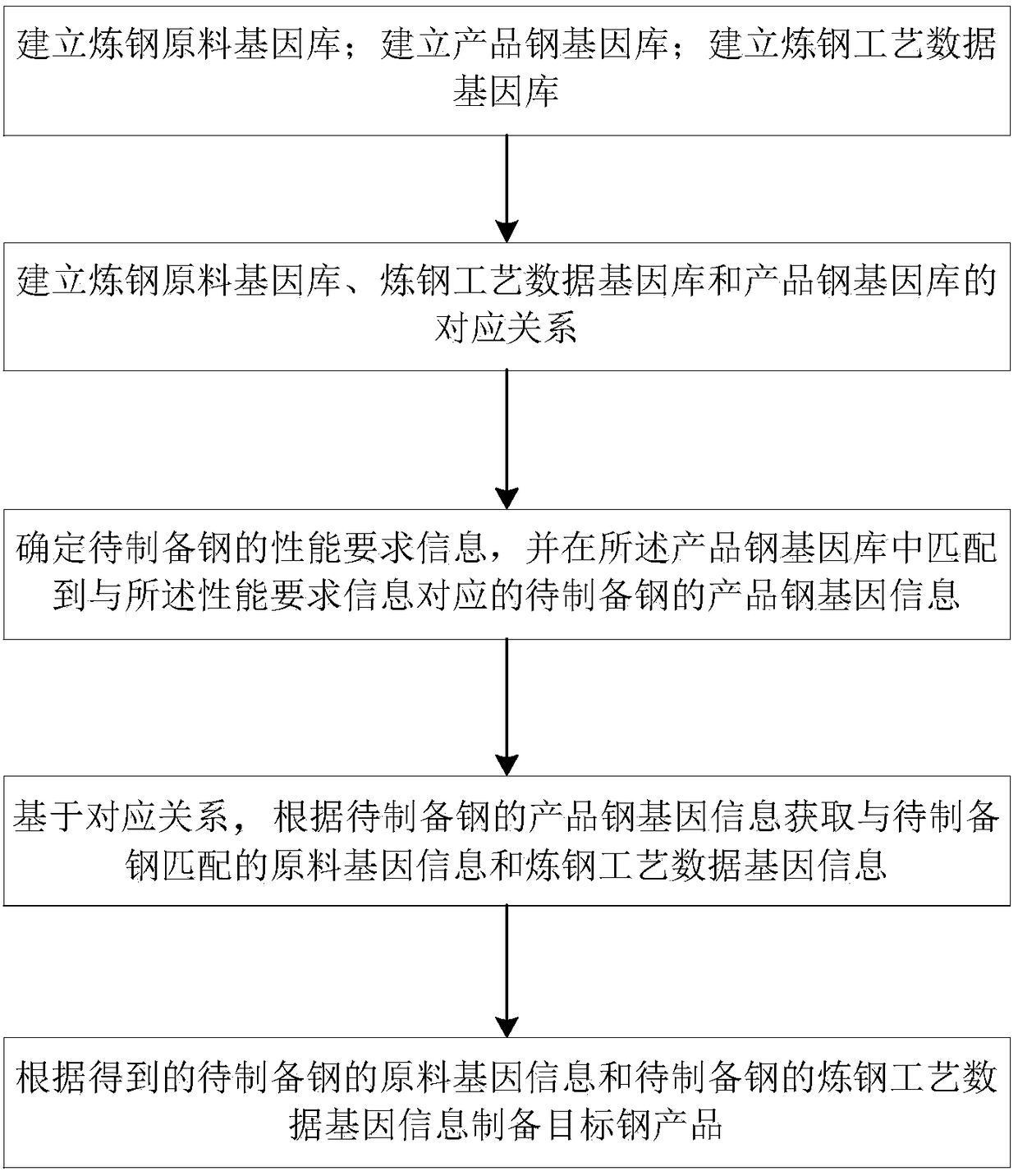

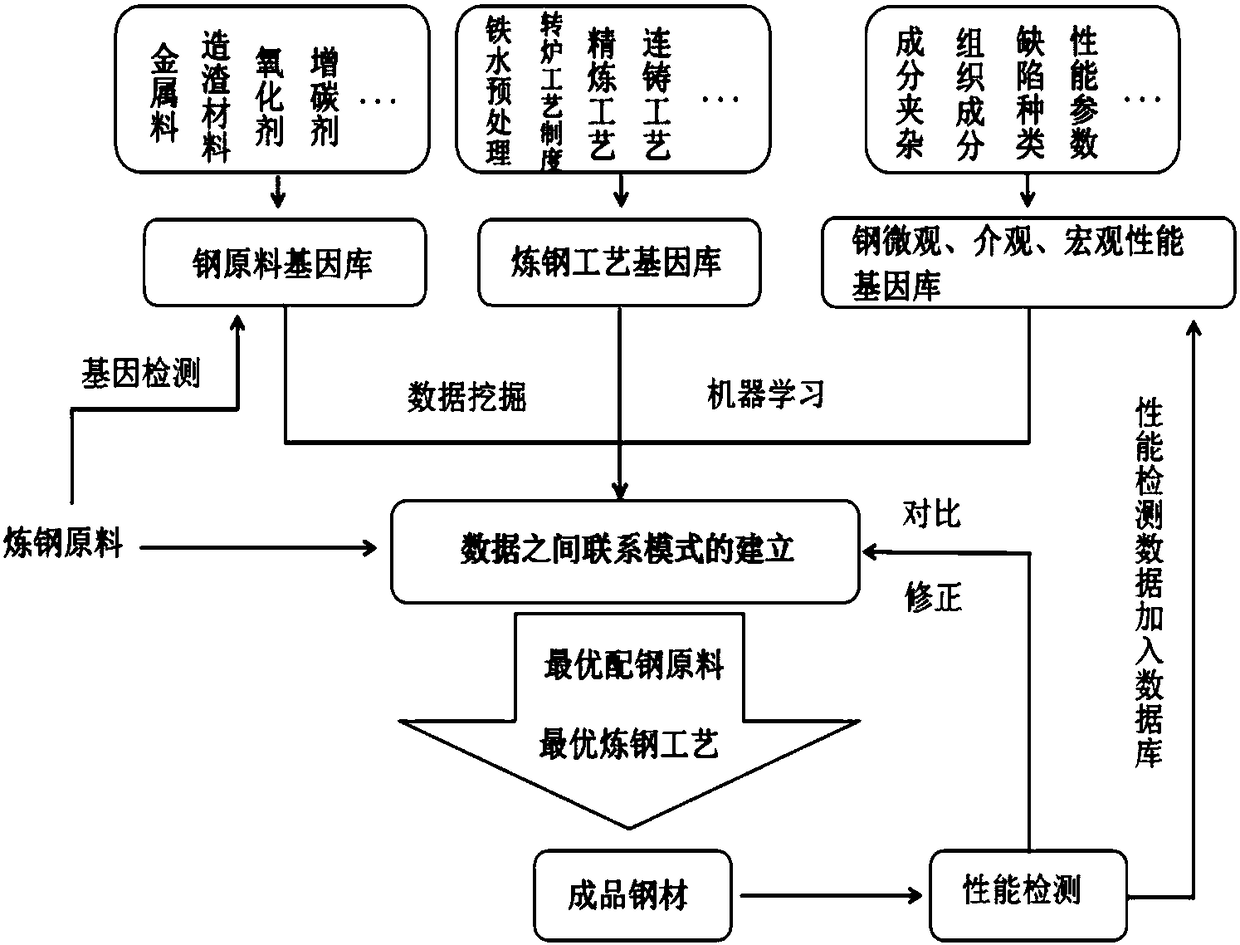

[0104] In specific embodiments, as figure 1 As shown, the gene bank-based steel preparation method includes the following steps:

[0105] 1) establishing a steel-making raw material gene bank, the steel-making raw material gene bank is composed of steel-making raw material gene information;

[0106] Establishing a product steel gene bank, the product steel gene bank is composed of product steel gene information;

[0107] establishing a steel-making process data gene bank, the steel-making process data gene bank being composed of steel-making process data gene information;

[0108] 2) Establish the corresponding relationship between the steel-making raw material gene bank, the steel-making process data gene bank and the product steel gene bank;

[0109] 3) determining the perfo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap