Driving circuit of organic light emitting display

A technology of light-emitting display and drive circuit, which is applied to static indicators, instruments, etc., can solve problems affecting the display brightness of organic light-emitting diodes (OLEDs), achieve the effect of improving accuracy and realizing narrow borders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

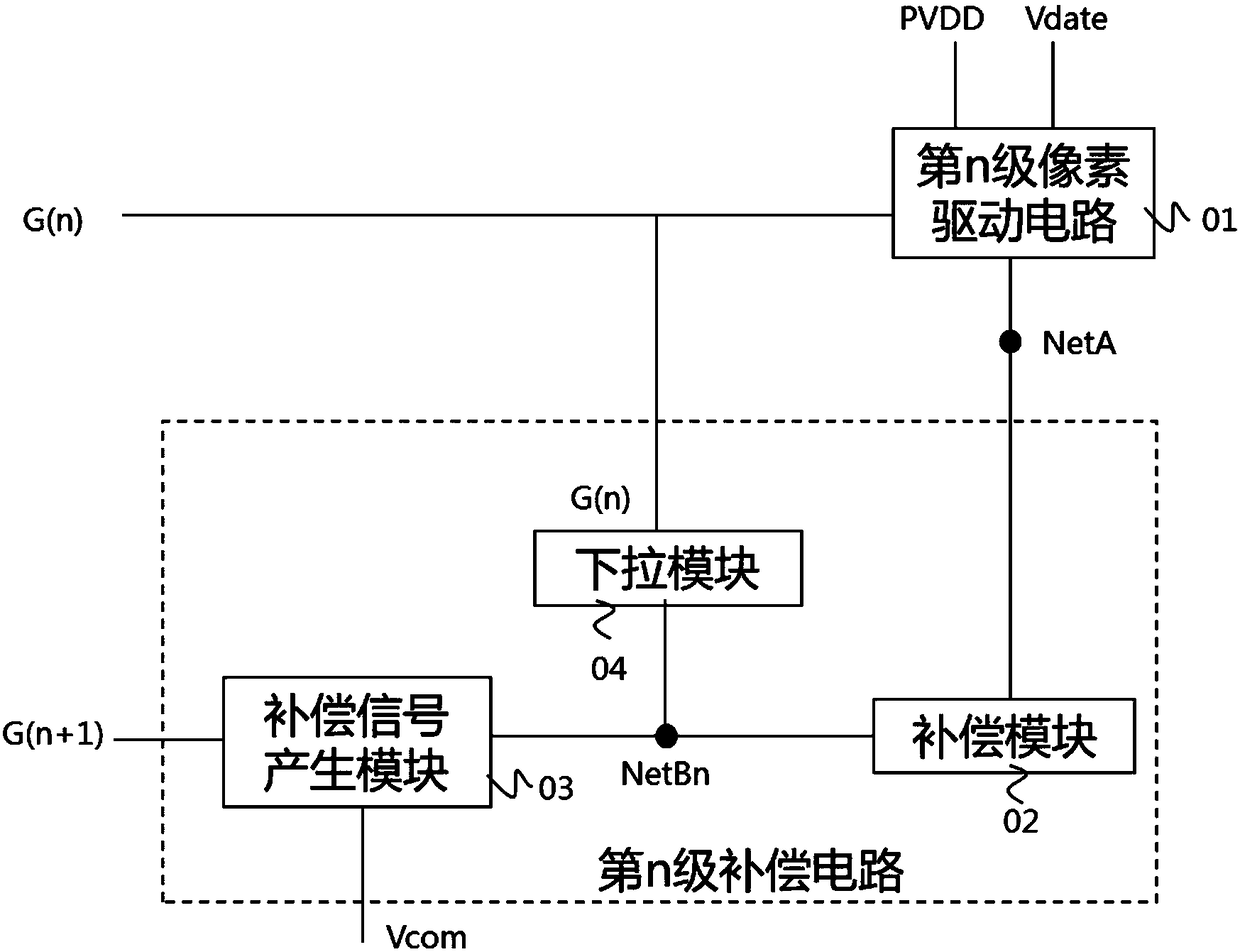

[0048] The organic light-emitting display in this embodiment includes N1 rows of scan lines and M columns of data lines (N1≥N>1, M>1 and N1 and M are integers), pixel areas defined by intersections of scan lines and data lines, and A driving circuit of an organic light emitting display composed of N-level driving circuit units. The nth (1≤n≤N) level driving circuit unit includes an nth level compensation circuit and a plurality of nth level pixel driving circuits.

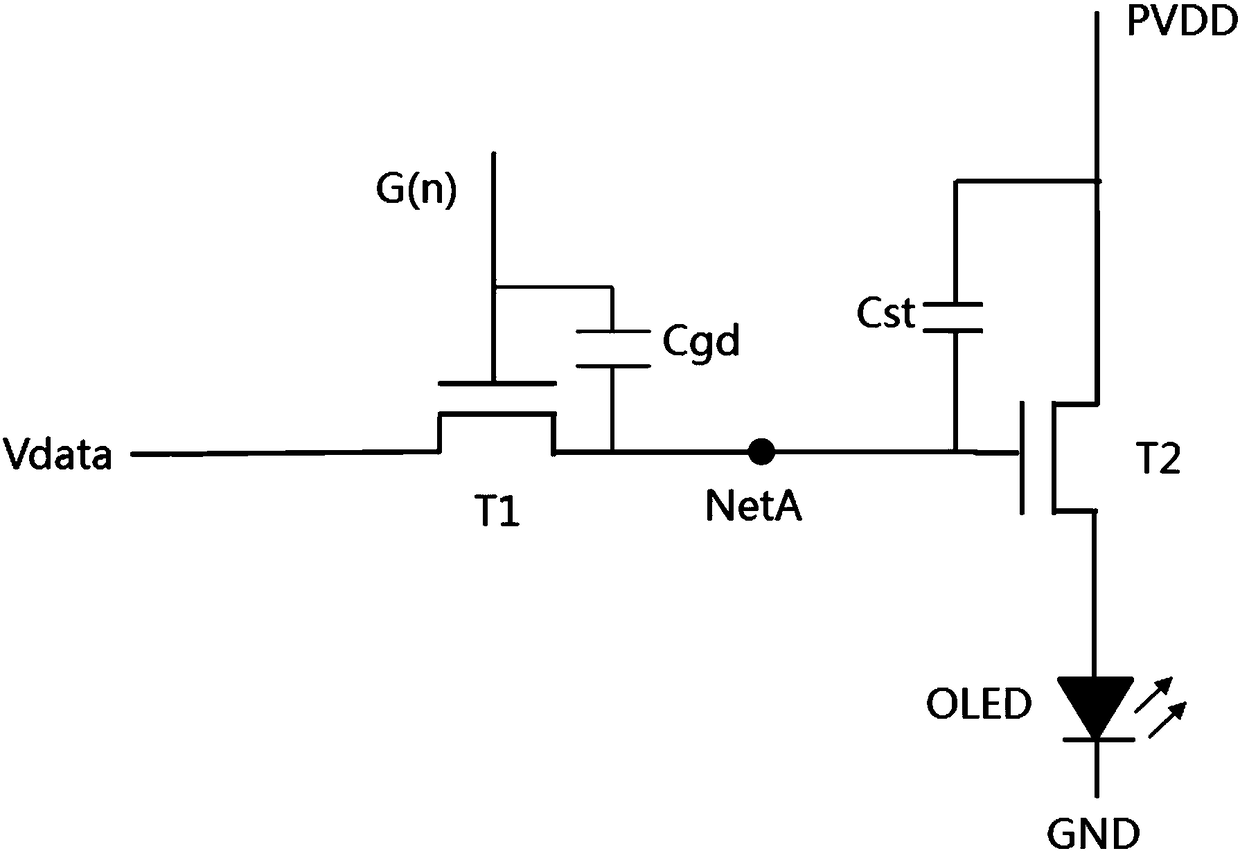

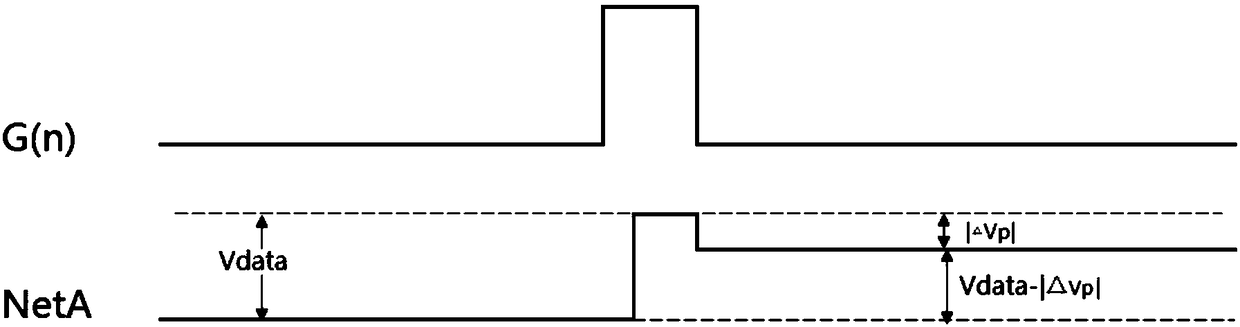

[0049] Figure 4 It shows the nth level compensation circuit and the kth region (1≤k≤N*M) pixel driving circuit belonging to one of the nth level pixel driving circuits, the kth region pixel driving circuit is located in the nth (1≤n≤N*M) pixel driving circuit ) in the mth (1≤m≤M) column pixel area, the kth area pixel driving circuit includes the kth area data node NetA(k), the nth level compensation circuit is connected to the kth area pixel driving circuit in the kth Zone data node NetA(k). The gate driving ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com