High-pressure forming shell of 3D composite board and fabrication technology thereof

A high-pressure forming, composite sheet technology, applied in printing process, synthetic resin layered products, printing of special varieties of printed matter, etc., can solve the problems of weak impact resistance, technical limitations, poor toughness, etc., and achieve process stability. The effect of good performance, simple production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

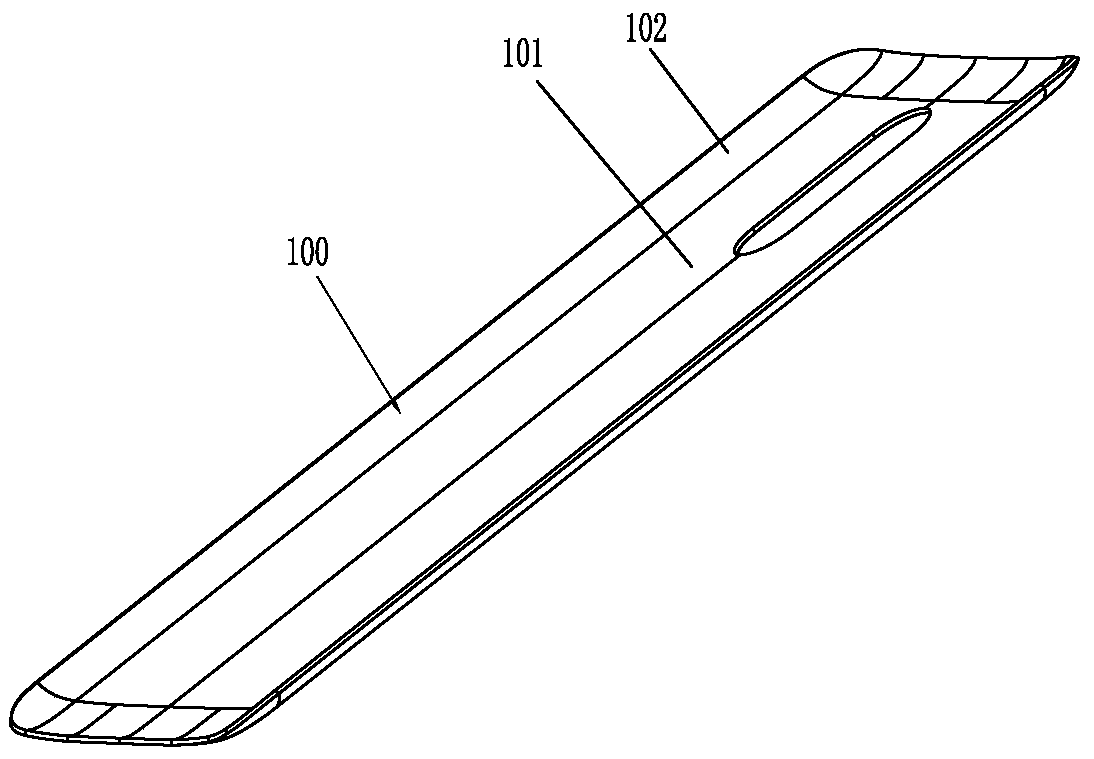

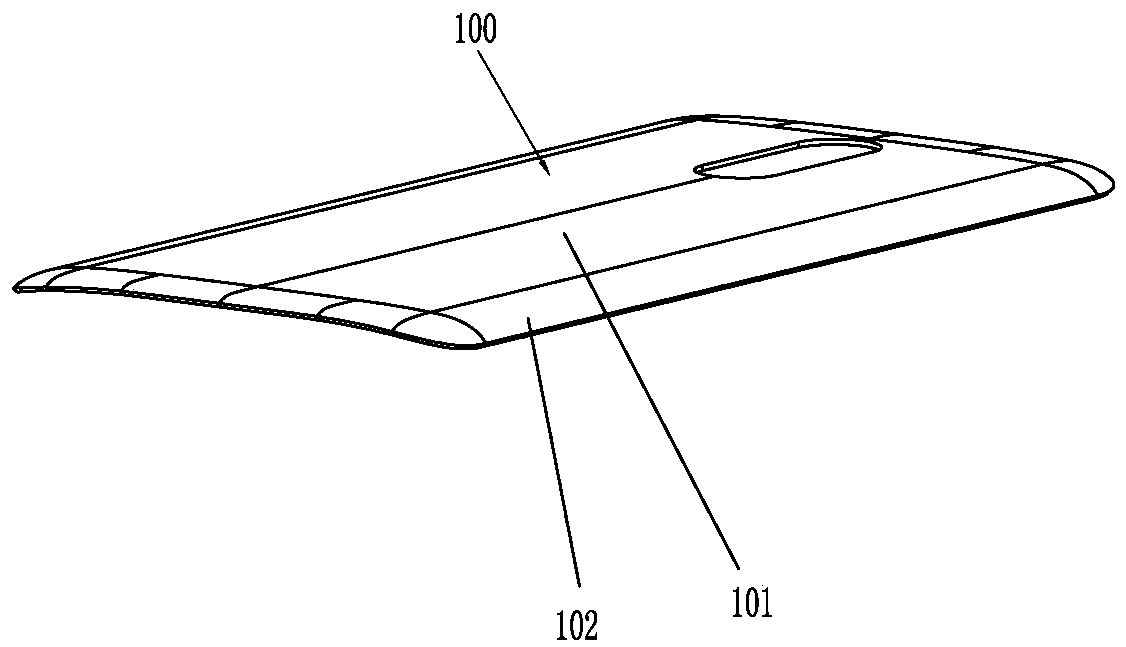

[0032] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the embodiment of the present invention.

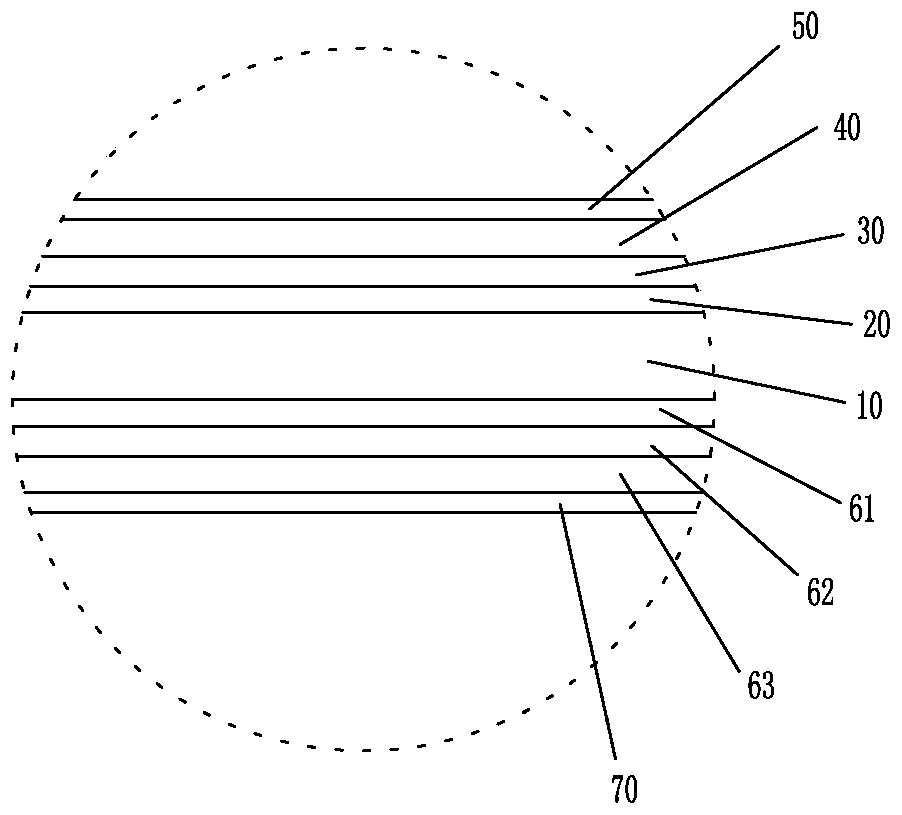

[0033] A 3D composite plate high-pressure formed shell, which is a curved shell 100, which has a transparent PC composite plate base 10, and the transparent PC composite plate base 10 has a first outer surface and a second outer surface arranged on opposite sides, and its The first outer surface is provided with mirror silver ink layer 20, UV transfer glue layer 30, optical coating layer 40, and hardness strengthening liquid layer 50 in sequence, and the second outer surface is provided with first color ink layer and second color ink layer in sequence. The ink layer 70, the second color ink layer 70 is the same color sub-color of the first color ink layer.

[0034] In this embodiment, the first color ink layer includes three first color ink layers arranged on the second outer surface in sequence, that is, the first first color ink layer 61 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com