Aluminosilicate AEI zeolite preparation

A technology of zeolite and alumina, applied in the field of preparing molecular sieves with AEI framework, can solve the problem of not providing information on the size of the reaction mixture and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

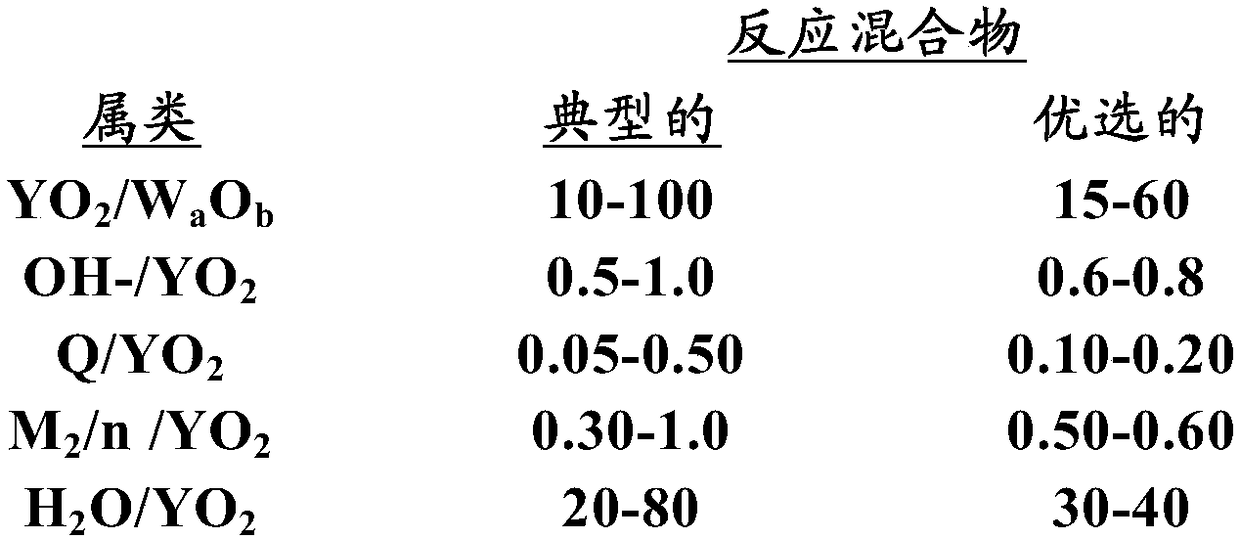

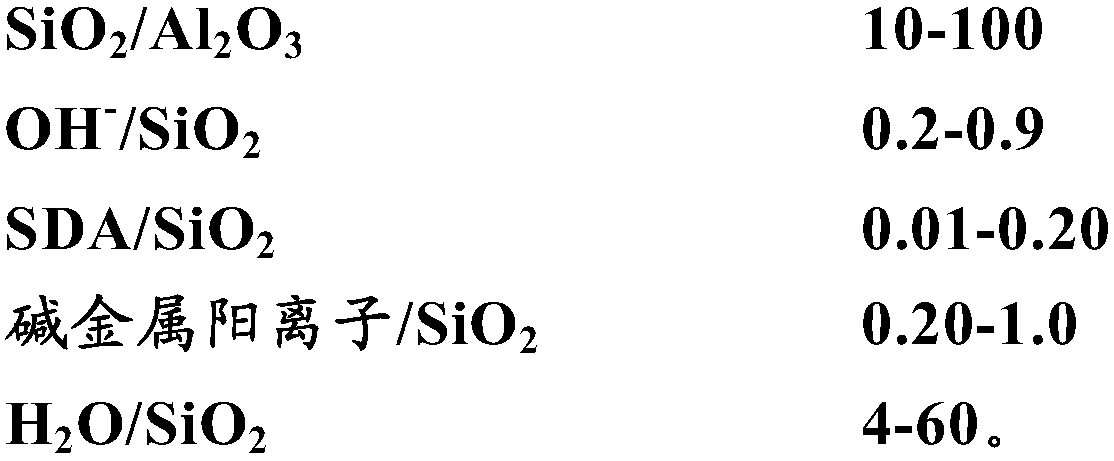

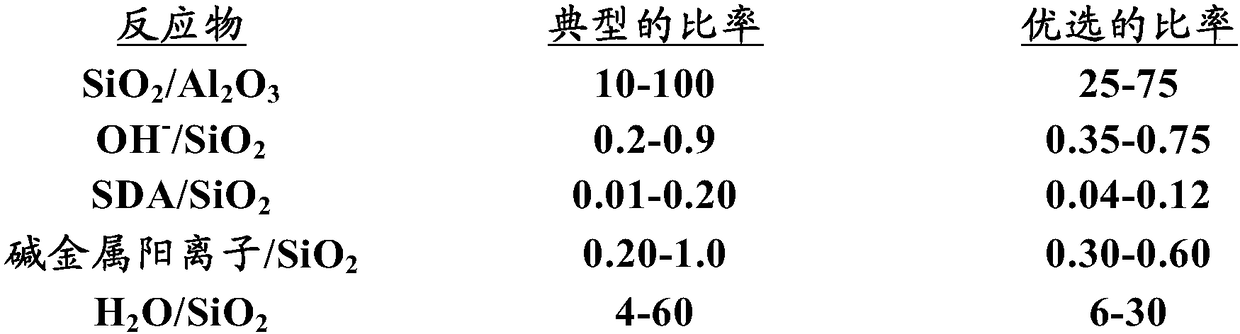

Method used

Image

Examples

preparation example Construction

[0034] A method of achieving a high yield of SDA in an AEI zeolite-based synthesis process comprises: (a) preparing a mixture comprising (i) at least one source of aluminum, (ii) at least one source of silica, (iii) at least one a source of hydroxide ions, and (iv) at least one AEI structure-directing agent (SDA); and b. reacting the mixture under crystallization conditions to form zeolite crystals with an AEI framework, the silica of the zeolite crystals being The alumina ratio (SAR) is from about 8 to about 50, inclusive. The relative yield of AEI on a molar basis based on SDA can be ≥ about 30%, ≥ about 35%, ≥ about 40%, ≥ about 45%, ≥ about 50%, ≥ about 55%, ≥ about 60%, ≥ about 65% %, > about 70%, > about 75%, > about 80%, > about 85%, > about 90%, or > about 95%.

[0035] A method for achieving high yields based on the weight of the reaction mixture in an AEI zeolite synthesis process comprising: (a.) preparing a mixture comprising (i) at least one source of aluminum, (...

Embodiment 1

[0115] SiO was synthesized according to the following procedure 2 / Al 2 o 3 AEI zeolite powder with a molar ratio (SAR) of 19.4. 35.0 g of industrial dealuminated USY (Al 2 o 3 = 11.79wt%, SiO 2 =74.31wt%), 945.7g of demineralized water, 303.15g of N,N-diethyl-3,5-dimethylpiperidinium hydroxide solution (20.0% water concentration) and 416.15g of sodium silicate solution (Na 2 O wt% = 9.00wt%, SiO 2 = 28.8 wt%) were mixed to form a synthetic gel. The formed synthetic gel was charged into a 2 L autoclave for reaction and crystallization of the AEI product. With stirring, the autoclave was heated to a target temperature of 145° C. over about 40 minutes and held at that target temperature. After 49 hours of crystallization, the solid product was recovered by filtration and washed with demineralized water until the pH of the filtrate dropped to 10 or lower. The filtered wet cake was dried in an oven at 120°C for about 10 hours to form a finished product containing SDA.

...

Embodiment 2-7

[0118] Examples 2-7 were prepared using the method of the invention and using N,N-diethyl-3,5-dimethylpiperidinium as SDA. These examples were performed in a 2.0 L reactor at a temperature of 160°C for 3 days, except Example 3, which was performed in a 0.6 L reactor at a temperature of 145°C for 1 day. In the description of "zeolites used", the term "heat-treated" means that the sample NaY was calcined at 600 °C for 2 hours, and then used for AEI synthesis. Na for each AEI sample produced 2 O wt% = 0.0. USY of SAR ~ 11 is similar to LZ-210 with SAR of 13 used in Examples 3-14 of US Patent 5,958,370.

[0119] The yields ("Yield") in the table below are the isolated weight of AEI compared to the weight of the reaction mixture (gel). Yields are also expressed based on SDA. These yields were evaluated based on experimental data as follows: from W 2 Initial reaction gel recovery W for g 1 g made AEI; made AEI SDA content (W SDA wt%) is measured by thermogravimetric analysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com