Sealing element, and fuel injector comprising a sealing element

A technology for fuel injectors and sealing components, applied in fuel injection devices, fuel injection valves driven by fluid pressure, special fuel injection devices, etc., can solve problems such as increased space requirements, and achieve compact layout, cheap and highly accurate manufacturing , Improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

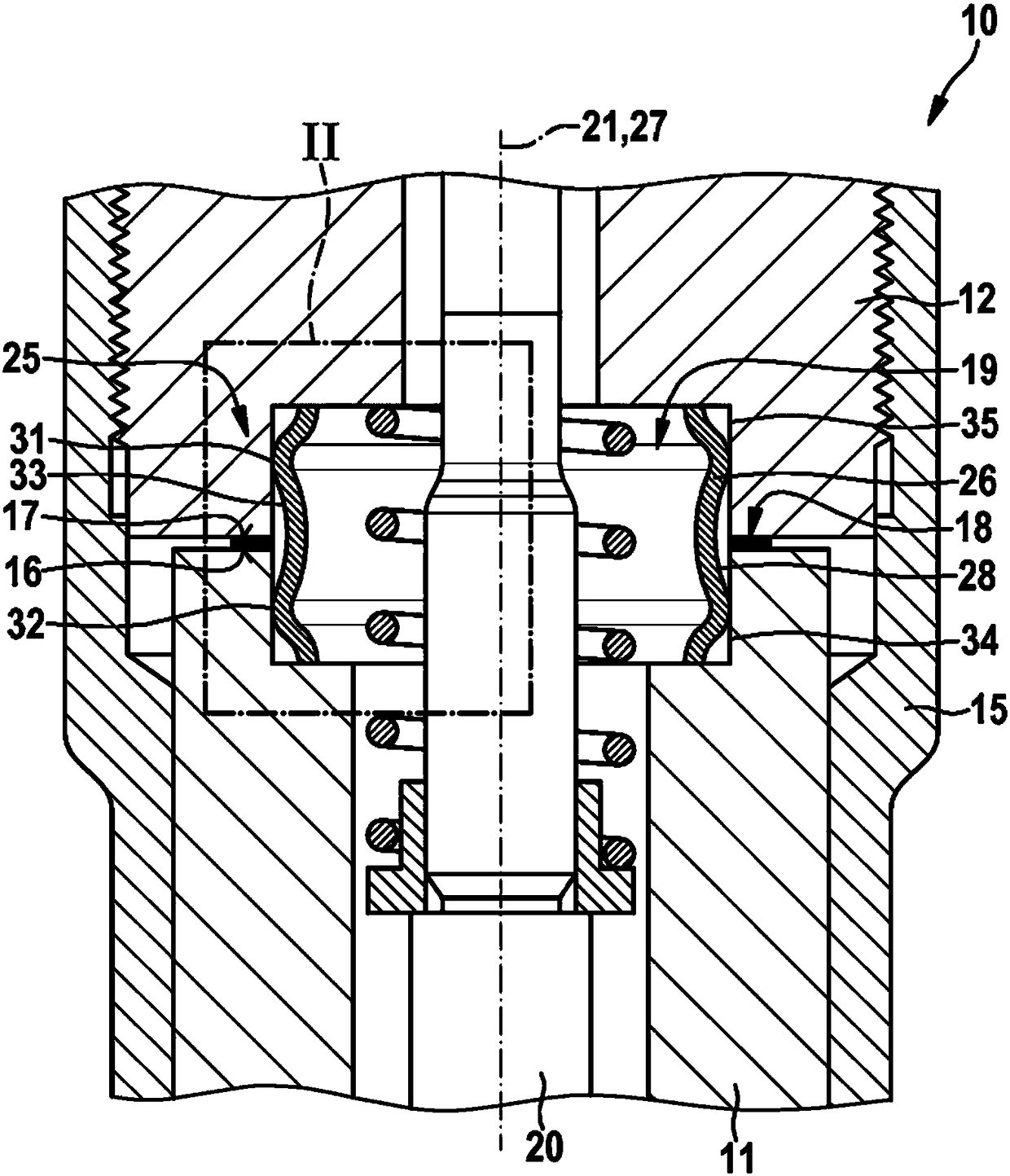

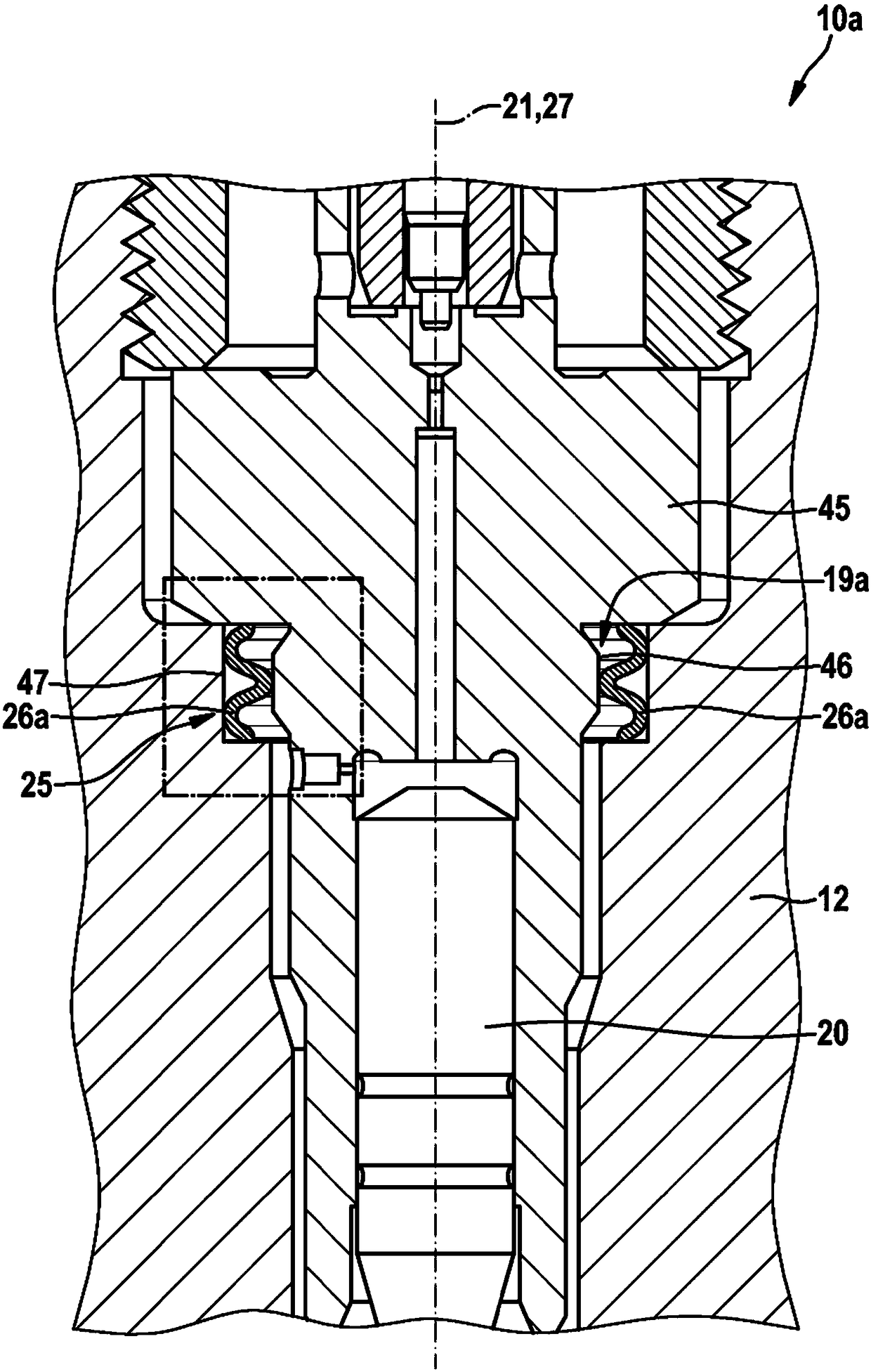

[0021] exist figure 1 A fuel injector 10 such as that shown in the center is used to inject fuel into a combustion chamber (not shown) of a compression ignition internal combustion engine. Fuel injector 10 is in particular designed as a so-called common rail injector.

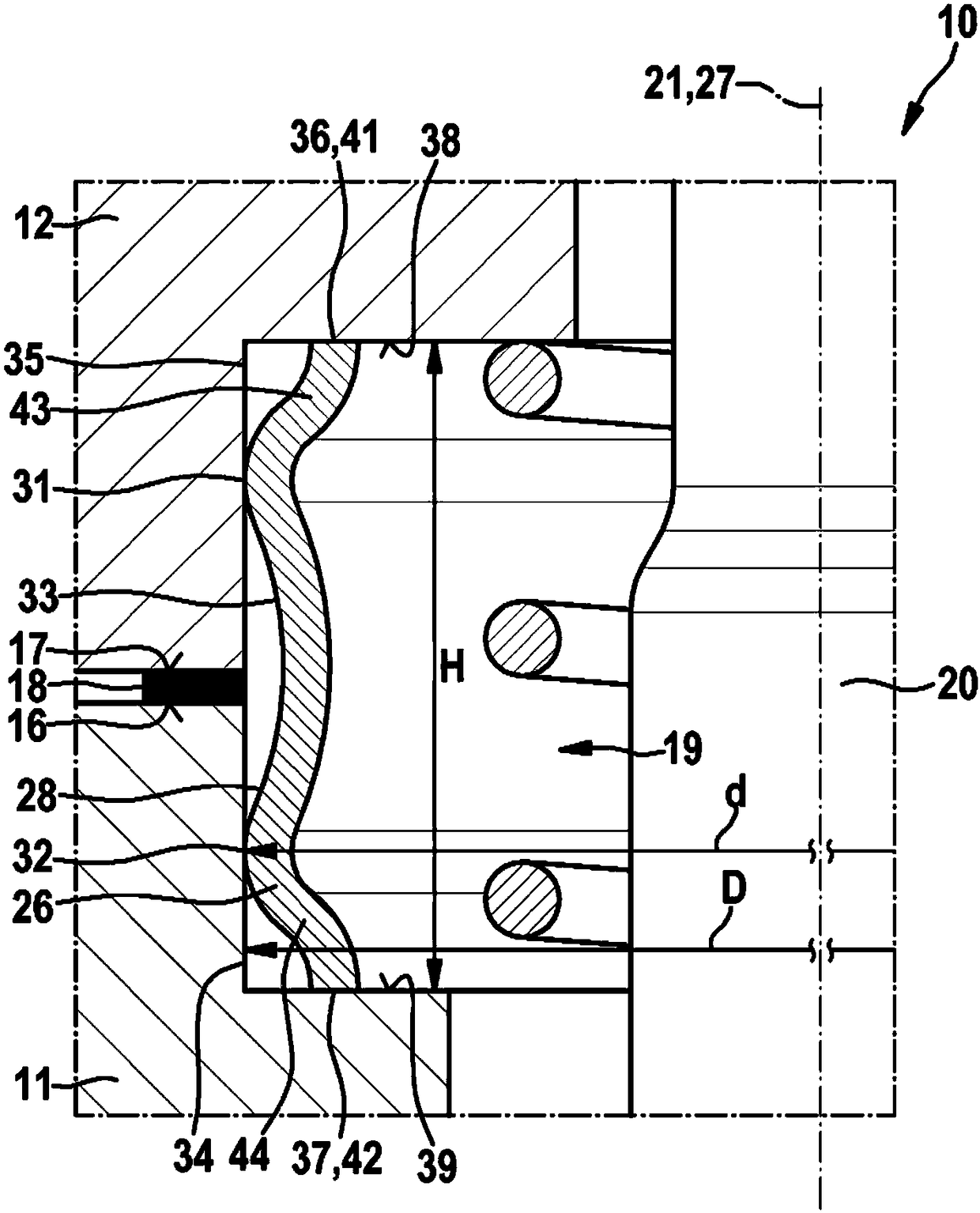

[0022] The fuel injector 10 has a nozzle body 11 , to which a holding body 12 adjoins in the direction opposite to an injection opening (not shown) of the nozzle body 11 . The nozzle body 11 and the holder body 12 are axially clamped by means of a nozzle clamping nut 15 . In particular, the nozzle body 11 and the holding body 12 are arranged in at least regional contact with each other in the region of the opposite end faces 16 , 17 in the installed state. exist figure 1 and 2 In the exemplary embodiment shown, it is ensured by corresponding machining of the end faces 16 , 17 that, in the state of the nozzle body 11 mounted axially on the holding body 12 , the two end faces 16 , 17 at least in the radially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com