Raw material curing and cooling device of artemisia integrifolia coarse cereal porridge production line and using method of device

A technology of cooling device and miscellaneous grain porridge, which is applied in the direction of food science, etc., can solve the problems of long cooling time, lower production efficiency, and affect the taste of food, so as to achieve reasonable design, improve production efficiency, and ensure the effect of eating taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

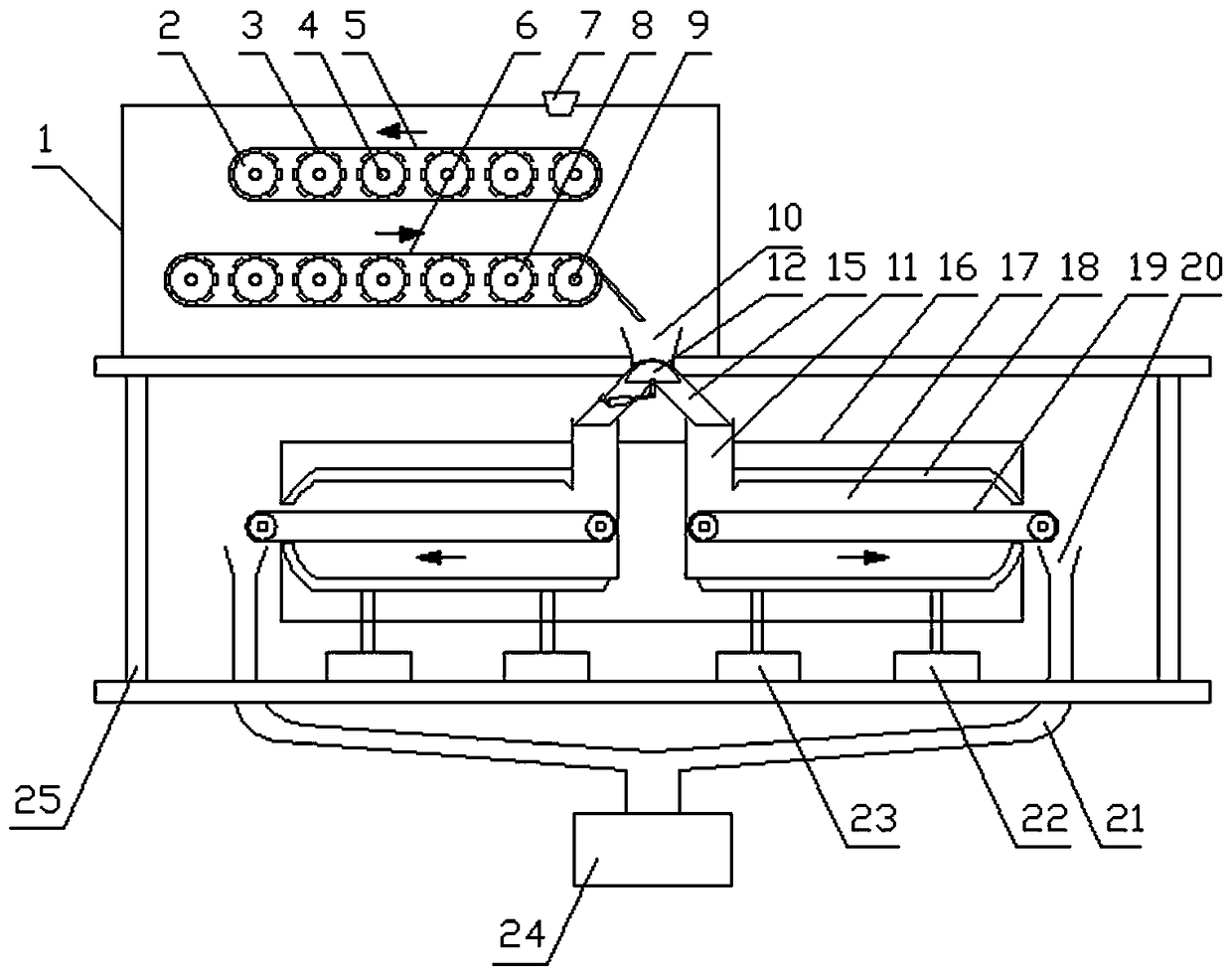

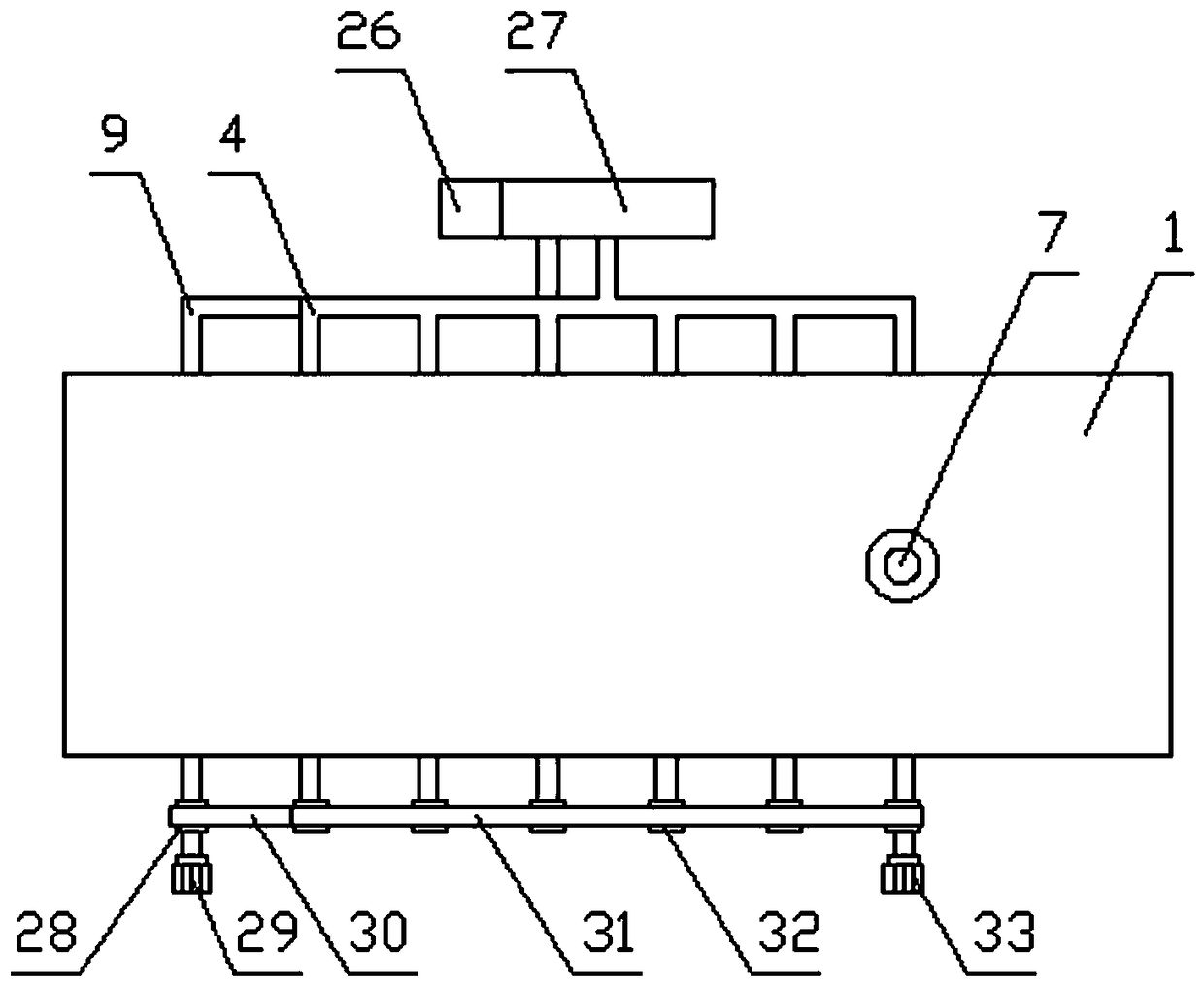

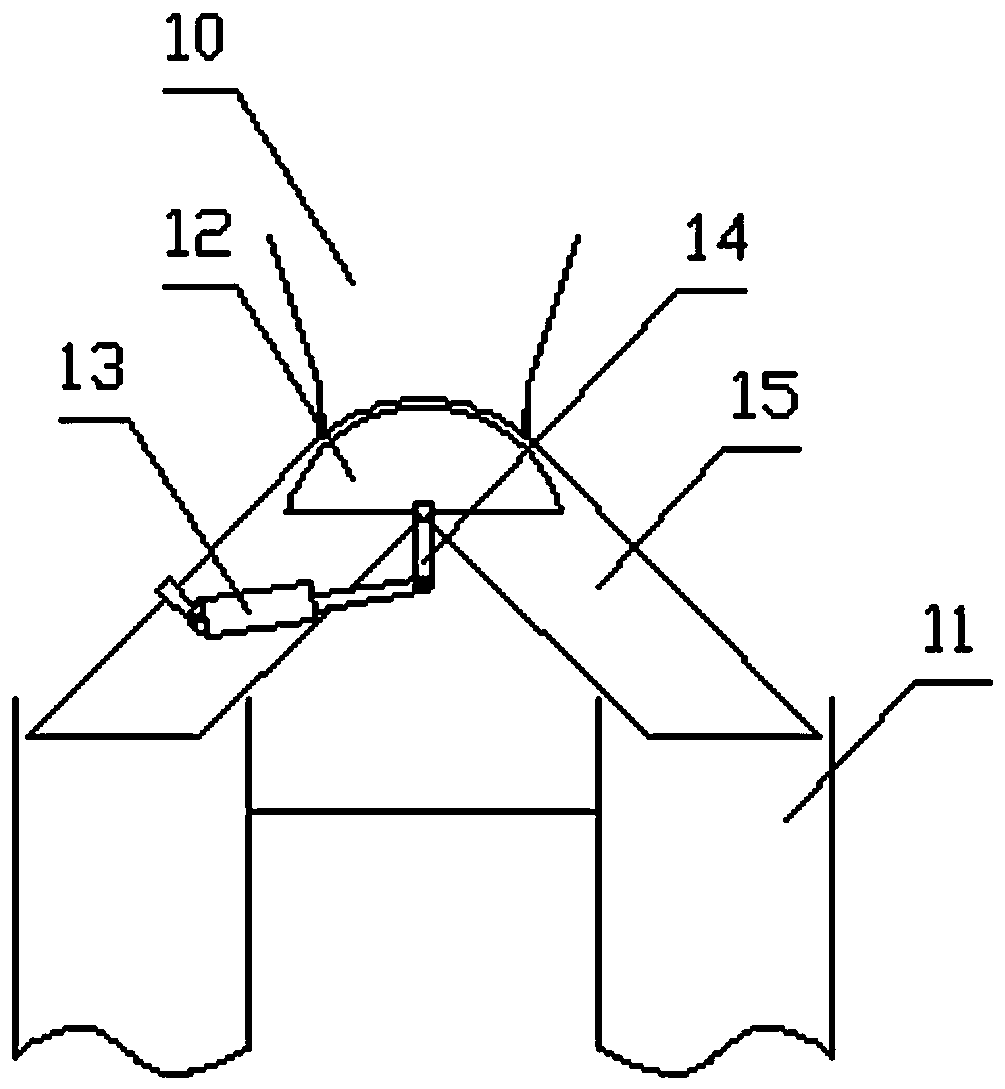

[0039] With reference to each figure, the present invention specifically adopts the following embodiments: comprising a device frame 25, a curing box 1, a cooling box 16 and a material storage box 24, the top of the device frame 25 is provided with a curing box 1, and the horizontal frame cooling box 16 in the middle of the device frame 25, Cooling box 16 below is provided with material storage box 24, and ripening box 1 top is provided with feed inlet 7, and below feed inlet 7 is provided with several first ripening round rollers 2, passes between the first ripening round rollers 2 through the first conveyor. The material belt 5 is connected, and several second curing round rollers 8 are arranged below the first curing round roller 2, and the second curing round rollers 8 are connected by the second transfer belt 6, and the second curing round roller 2 and the first curing The outer circumferential surface of the round roller 2 is provided with cooling outlets 3, the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com