Online monitoring and combined protection system for reducing and sizing mill

A protection system, reduction and sizing technology, applied in the field of on-line monitoring combined protection system of the reduction and sizing unit, can solve the problems of untimely shutdown and maintenance, long production line downtime, and economical scrapping of the whole machine, so as to reduce the loss of failure and avoid failure Increased weight and improved product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

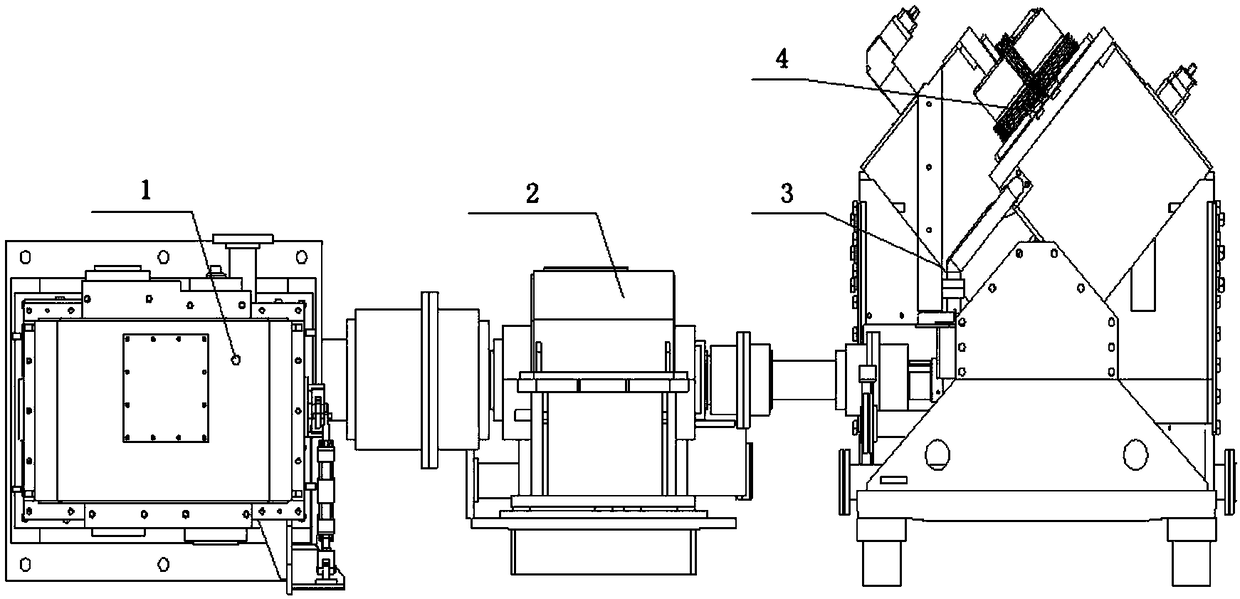

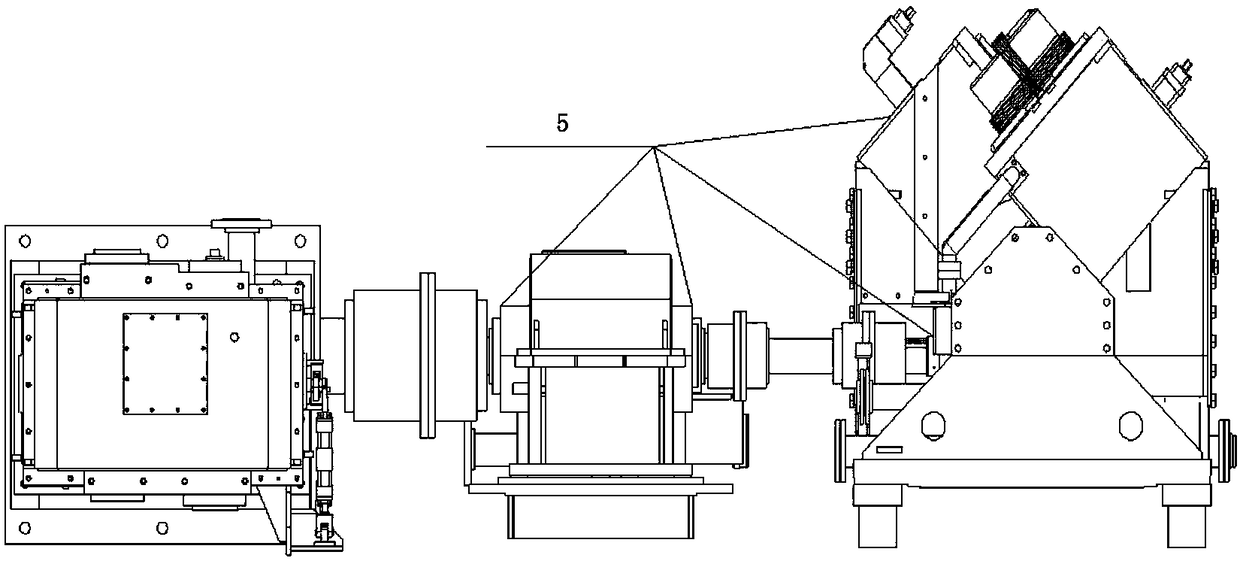

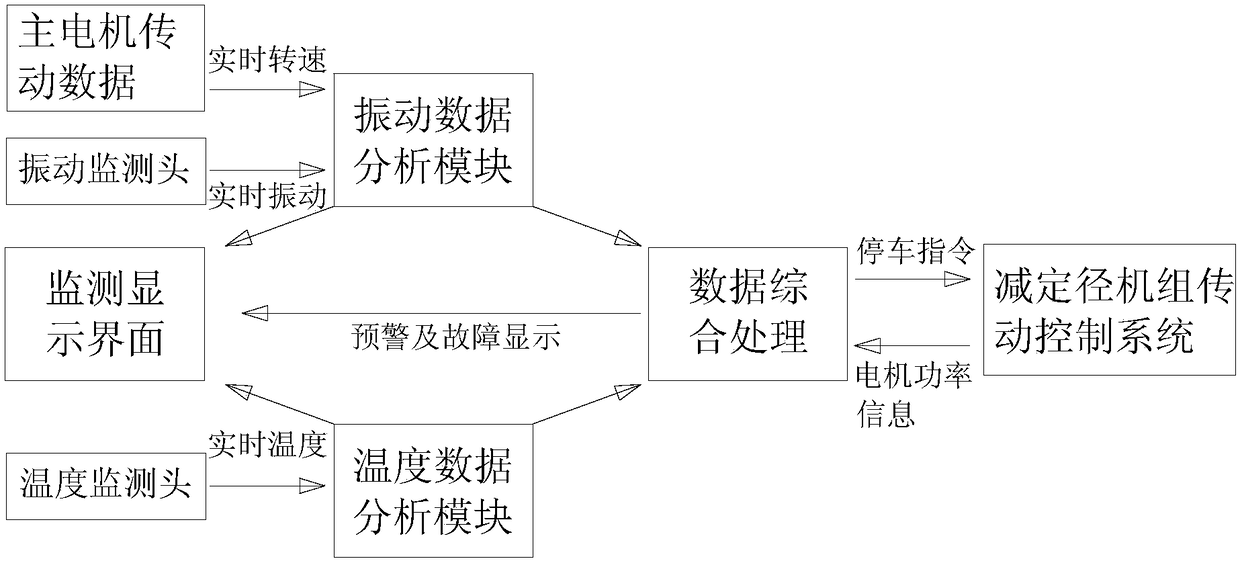

[0017] Such as image 3 As shown, an on-line monitoring combined protection system for reducing and sizing units includes an on-line vibration detection and analysis module and an on-line temperature detection and analysis module. Transmission model, refer to the input speed to obtain the real-time frequency of each position, monitor the vibration amplitude change of each frequency, when the vibration amplitude of a certain frequency exceeds the regular change or increases to the set value, the system will issue an early warning or issue a stop command and display a fault location, to remind the site to carry out maintenance and treatment of equipment failures. The temperature online detection and analysis module monitors the temperature of each oil film bearing position, and establishes a Corresponding associated data model, when the temperature rise rate is fast or exceeds the set value, an early warning and automatic stop command will be issued and the high temperature posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com