A welding jig

A welding fixture and clamping technology, which is applied in the field of tooling and fixtures, can solve the problems of low cleaning efficiency, inability to fully achieve, increase the difficulty of welding work, etc., and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a further detailed description through specific implementations:

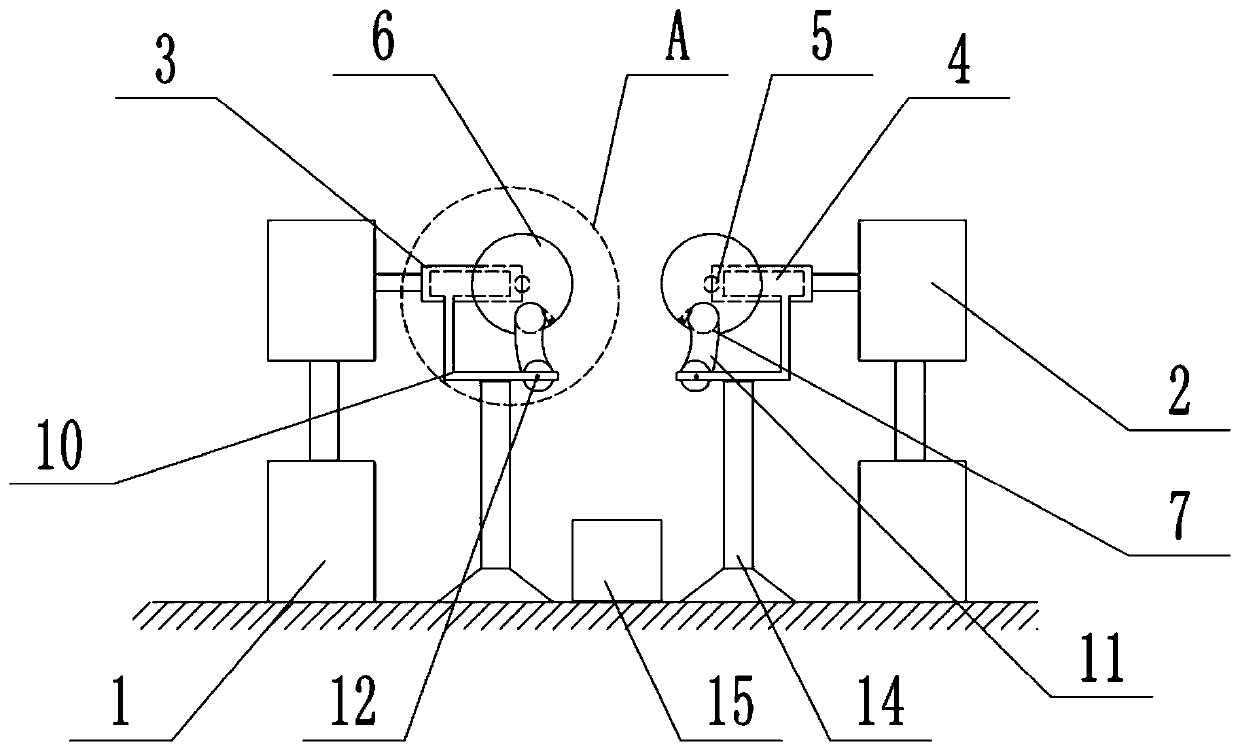

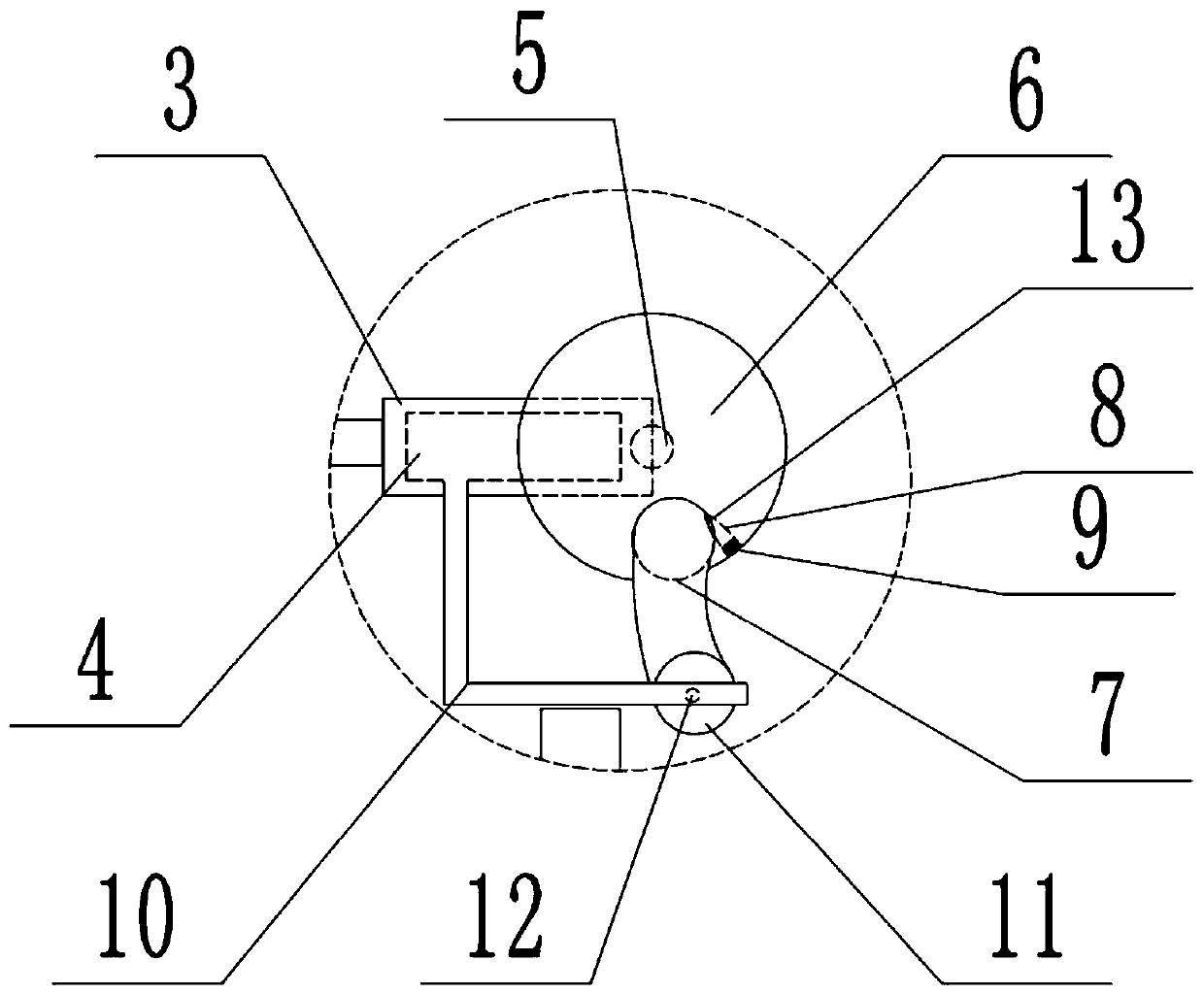

[0025] The reference signs in the drawings of the specification include: hydraulic cylinder 1, electric push rod 2, support block 3, cavity 4, motor 5, clamping roller 6, through groove 7, spray channel 8, nozzle 9, pipe 10, The strip bag 11, the liquid inlet check valve 12, the liquid outlet check valve 13, the support seat 14, and the recovery box 15.

[0026] Such as figure 1 As shown, a welding fixture of the present invention includes a clamping unit arranged symmetrically, the clamping unit includes a hydraulic cylinder 1, the output end of the hydraulic cylinder 1 is fixedly connected with an electric push rod 2, the hydraulic cylinder 1 and the electric push rod 2 signals A controller is connected, and the controller is used to control the linear movement distance of the output end of the hydraulic cylinder 1 and the electric push rod 2.

[0027] Such as figure 2 As shown, the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com