Surface shaping method of injection molding element and injection molding element

A technology of injection molded parts and injection molding, which is applied in the field of coating preparation, can solve the problems of weakening product competitiveness, hindering the application of painting, and increasing costs, so as to achieve the effects of improving product competitiveness, reducing painting processes, and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings. Wherein the same parts are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings. The terms "inner" and "outer" are used to refer to directions toward or away from the geometric center of a particular component, respectively.

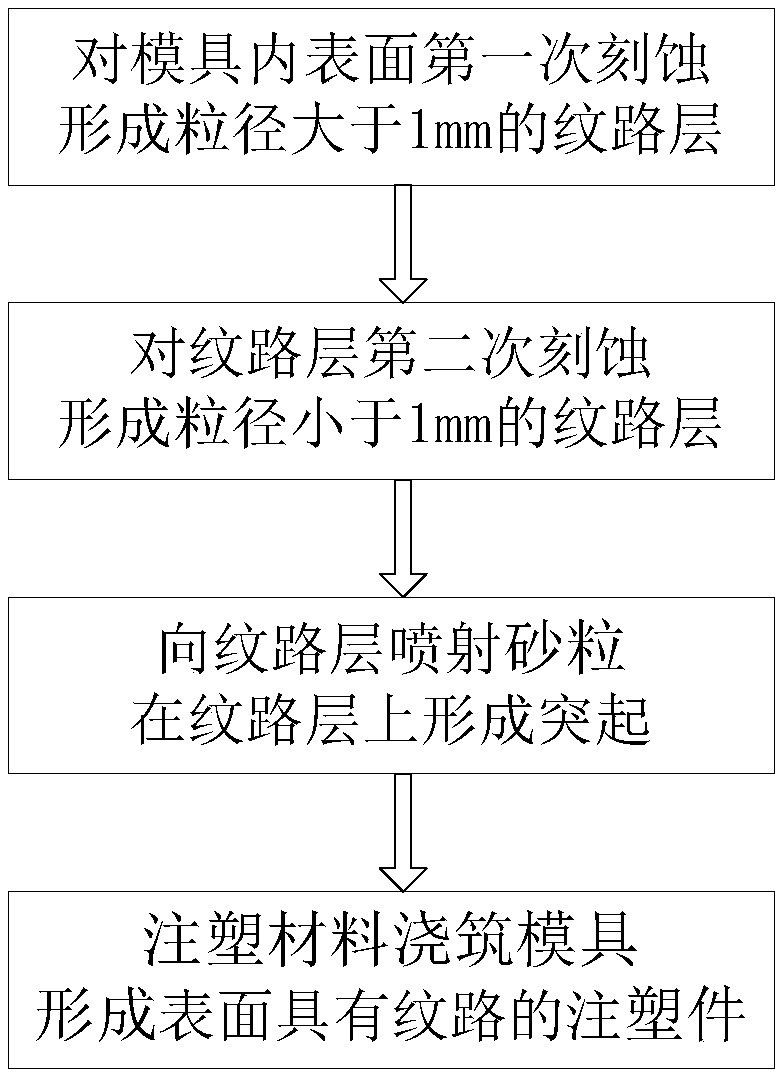

[0029] figure 1 It is a schematic flow chart of the surface shaping method of the injection molded part adopted in the specific embodiment of the present invention. like figure 1 As shown, the surface shaping methods of injection molded parts include:

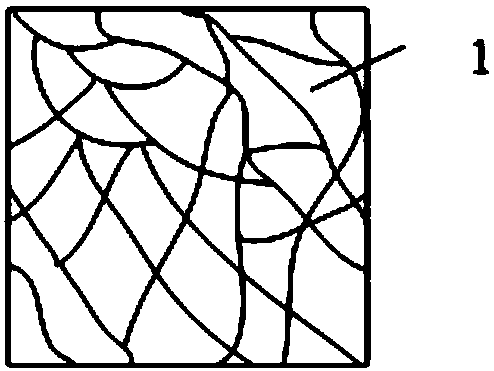

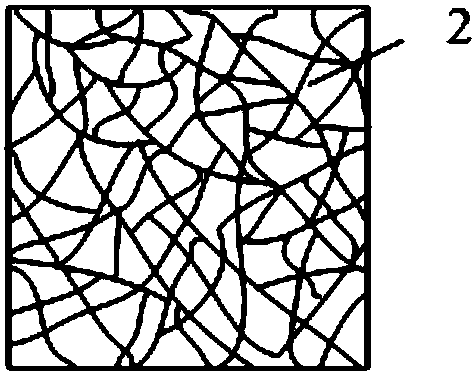

[0030] (1) The inner surface of the mold for forming the injection part is etched for the first time, and a textured layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com