Photoelectric positioner for transportmanipulator and positioning method thereof

A technology of positioner and manipulator, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of shortened service life, inconvenient use, no protective measures, etc., to enhance cold and heat resistance, facilitate transmission of information, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

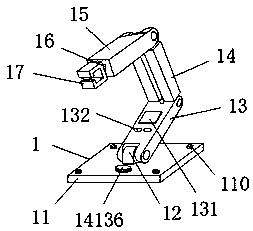

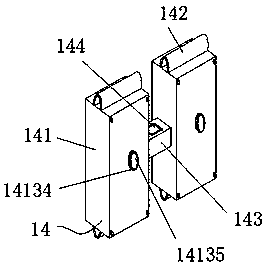

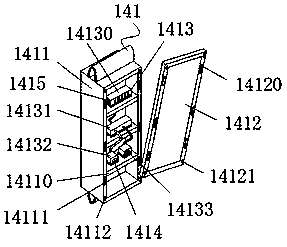

[0040] see Figure 1-4 , the present invention provides the following technical solutions: a photoelectric positioner for a transport manipulator and its positioning method, comprising a transport manipulator body 1, a fixed seat 11, a rotating shaft 12, a first rotating arm 13, a photoelectric positioning mechanism 14, and a second rotating arm 15 , the transmission part 16 and the manipulator 17, the handling manipulator body 1 includes a fixed seat 11, a rotating shaft 12, a first arm 13, a photoelectric positioning mechanism 14, a second arm 15, a transmission part 16 and a manipulator 17, wherein the fixed seat 11 The first rotating arm 13 is arranged above, and the fixed seat 11 is connected with the first rotating arm 13 through the rotating shaft 12. The side of the transport manipulator body 1 away from the fixed seat 11 is provided with a photoelectric positioning mechanism 14, and the photoelectric positioning mechanism 14 is far away from the first rotating arm 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com