Preparation method for three-layer anti-down elastic down feather fabric of displacement structure

A technology of down fabric and anti-drilling down fabric, which is applied in the field of clothing fabric manufacturing, can solve the problems of complex weaving, poor comfort, unsightly cost, etc., and achieve the effect of low cost, maintaining aesthetics, and maintaining dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a three-layer heterotopic structure anti-drilling down elastic down fabric, the steps are as follows:

[0042] (1) take polyester POY high elastic yarn as warp yarn and weft yarn, fabric I is obtained by weaving, the specification of warp yarn is 40D50F, the specification of weft yarn is 70D10F, the density of warp yarn is 510 / 10cm, and the density of weft yarn is 510 / 10cm, fabric The fabric organization of I is plain weave;

[0043] (2) Dyeing and setting: adopt overflow process to dye fabric I, then add super positioning and setting to obtain fabric II, adding super positioning and setting is carried out according to the output cylinder width of cloth;

[0044] (3) High temperature pre-shrinking: fabric II is placed in steam at 205°C for 3 minutes to obtain fabric III;

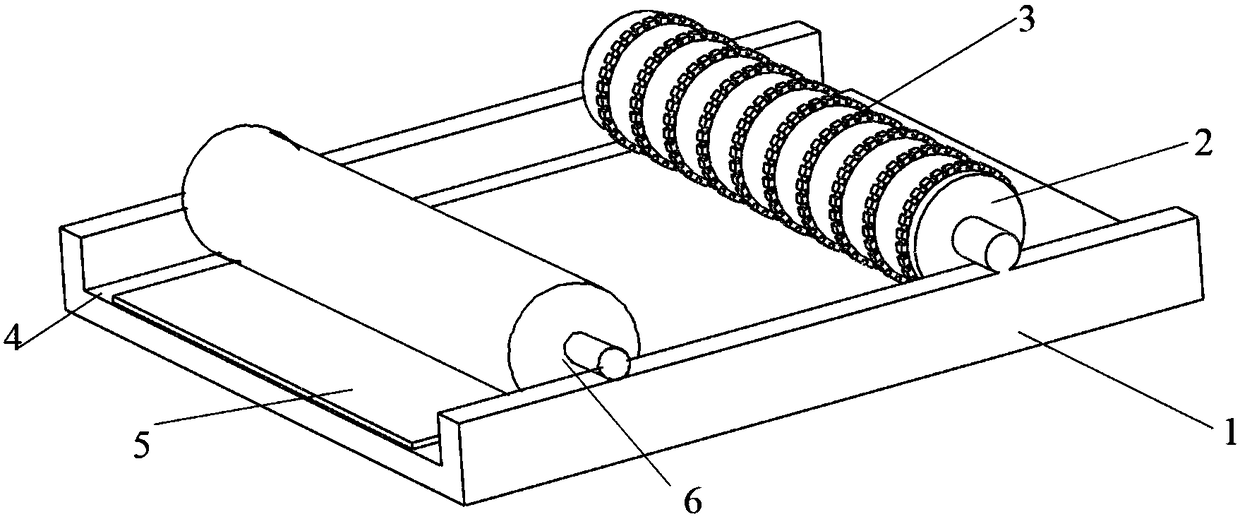

[0045] (4) Calendering treatment: Perform preliminary calendering treatment I, preliminary calendering treatment II and mirror calendering treatment on fabric III in turn to o...

Embodiment 2

[0059] A preparation method of a three-layer heterotopic structure anti-drilling down elastic down fabric, the steps are as follows:

[0060] (1) take polyester POY high elastic yarn as warp yarn and weft yarn, fabric I is obtained by weaving, the specification of warp yarn is 70D10F, the specification of weft yarn is 40D50F, the density of warp yarn is 600 / 10cm, and the density of weft yarn is 600 / 10cm, fabric The fabric structure of I is twill weave;

[0061] (2) Dyeing and setting: adopt overflow process to dye fabric I, then add super positioning and setting to obtain fabric II, adding super positioning and setting is carried out according to the output cylinder width of cloth;

[0062] (3) High temperature pre-shrinking: fabric II was placed in steam at 225°C for 5 minutes to obtain fabric III;

[0063] (4) Calendering treatment: Perform preliminary calendering treatment I, preliminary calendering treatment II and mirror calendering treatment on fabric III in turn to obt...

Embodiment 3

[0071] A preparation method of a three-layer heterotopic structure anti-drilling down elastic down fabric, the steps are as follows:

[0072] (1) take polyester POY high elastic yarn as warp yarn and weft yarn, fabric I is obtained by weaving, and the specification of warp yarn is 50D72F, and the specification of weft yarn is 50D72F, and the density of warp yarn is 555 / 10cm, and the density of weft yarn is 555 / 10cm, fabric The weave of I is satin weave;

[0073](2) Dyeing and setting: adopt overflow process to dye fabric I, then add super positioning and setting to obtain fabric II, adding super positioning and setting is carried out according to the output cylinder width of cloth;

[0074] (3) High temperature pre-shrinking: fabric II was placed in steam at 215°C for 4 minutes to obtain fabric III;

[0075] (4) Calendering treatment: Perform preliminary calendering treatment I, preliminary calendering treatment II and mirror calendering treatment on fabric III in turn to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com