A tunnel cement concrete pavement structure and laying method

A cement concrete and reinforced concrete technology, applied in the directions of roads, roads, pavement details, etc., can solve the problems of anti-slip attenuation of tunnel cement pavement, easy accumulation of water in tunnels, etc., and achieve the effect of improving drainage efficiency, small building area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

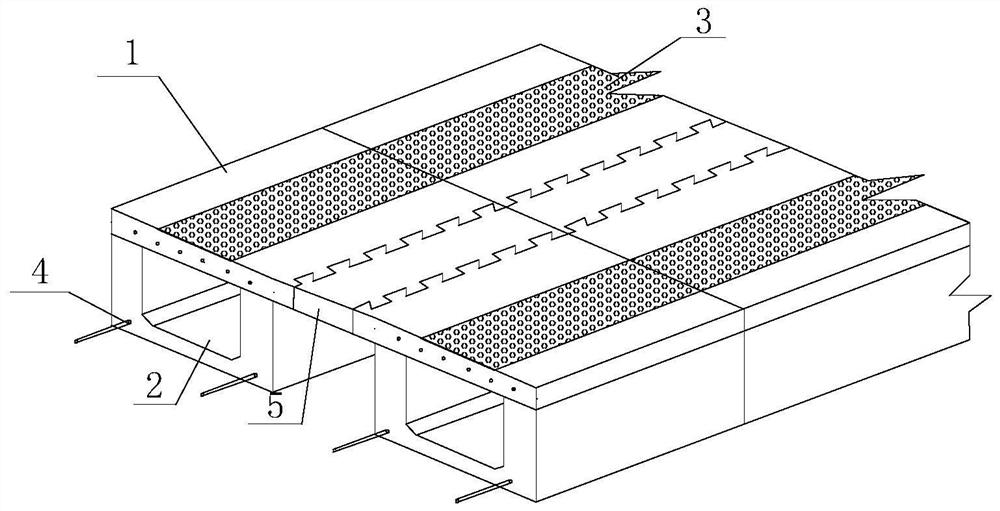

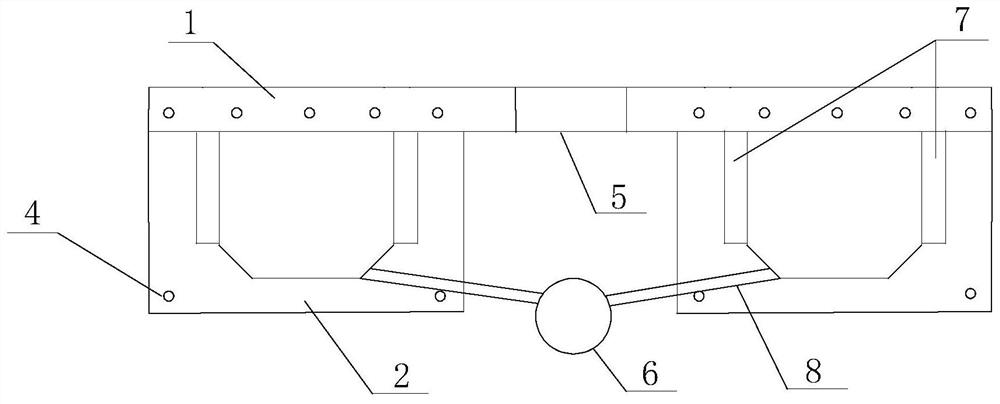

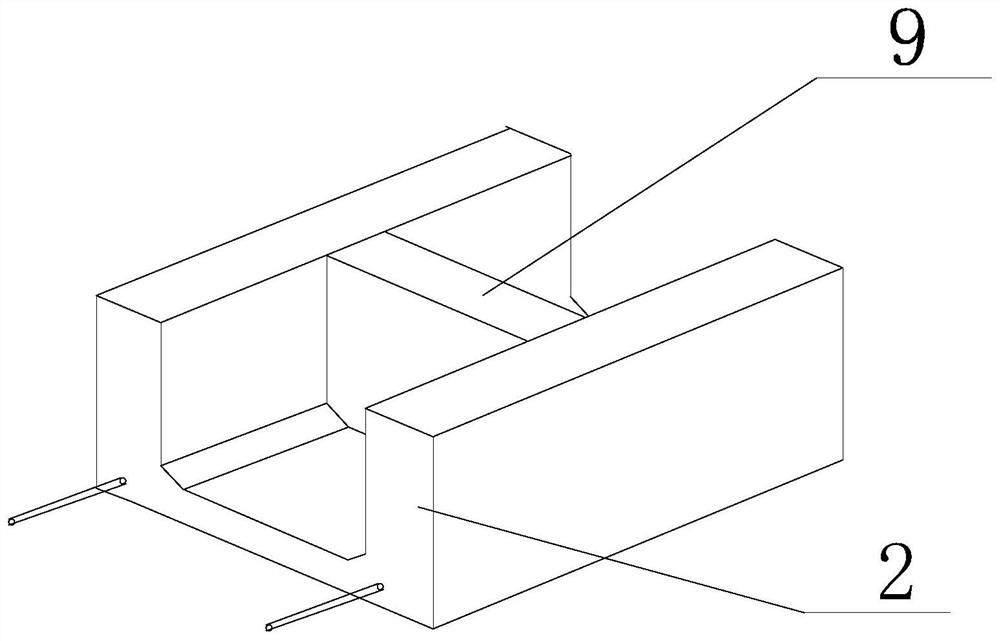

[0025] like Figure 1 to Figure 5 As shown, a structure for a tunnel cement concrete pavement includes a pavement reinforced concrete cover plate 1, a reinforced concrete U-shaped groove 2, a central connecting plate 5 and a drainage pipe 6 located below the central connecting plate 5, and the pavement reinforced concrete cover plate 1 is set. Above the reinforced concrete U-shaped groove 2, the pavement reinforced concrete cover plate 1 is provided with a plurality of through holes 3, the central connecting plate 5 is used to connect two road reinforced concrete cover plates 1, the two sides of the central connecting plate 5 and the reinforced concrete The connecting side of the U-shaped groove 2 and the central connecting plate 5 is provided with a serrated connection structure, which is convenient for the connection, installation and disassembly of the central conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com