Torsion support with vertical displacement function

A technology of torsion bearing and vertical displacement, applied in bridge parts, bridges, buildings, etc., can solve the problems of safe operation of bridge structures, passenger comfort, normal use of bridges, and fatigue damage of bridge structures. The effect of external energy input, enhancing safety and avoiding brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

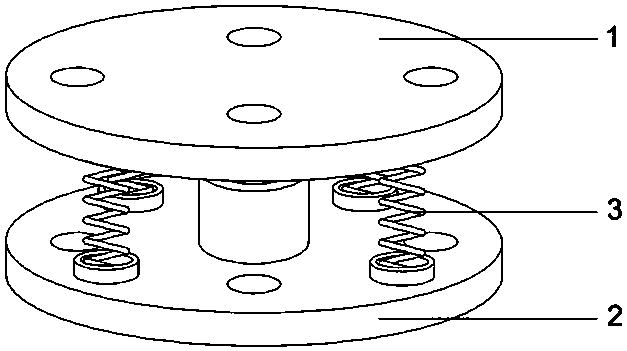

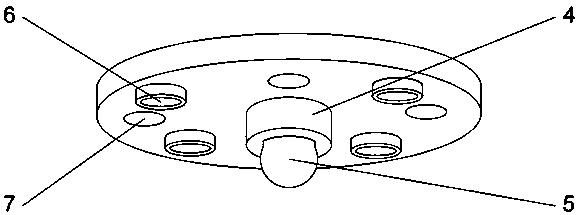

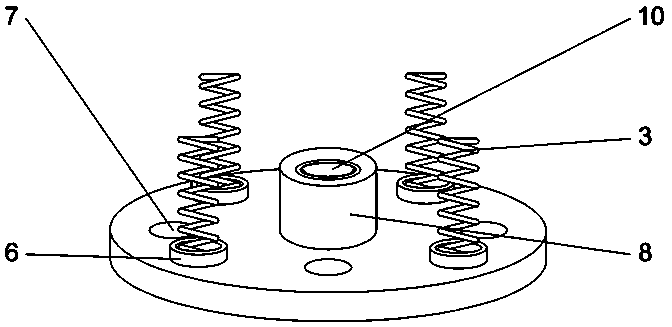

[0023] Such as figure 1 As shown, the present invention is a torsional support with vertical displacement, which can provide angular displacement and vertical translational displacement around the X-axis, Y-axis, Z-axis and the coupling of the three, and has an automatic reset function. The support consists of three parts from top to bottom: a support top plate 1, a position control spring 3, and a support bottom plate 2. Both the support top plate 1 and the support bottom plate 2 are in the shape of a flat cylinder, arranged up and down, and the horizontal projection area of the two is the same. At the center of the two, the support bottom plate 2 lifts the support top plate 1 through support, and at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com