Modular steel structure house suitable for high earthquake intensity area

A high-seismic-intensity, modular technology, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of unusable and reduced construction efficiency of modular integrated houses, so as to save resources, improve construction efficiency, and good heat preservation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

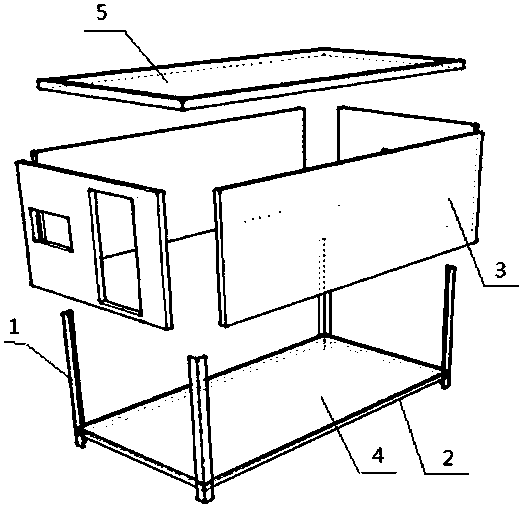

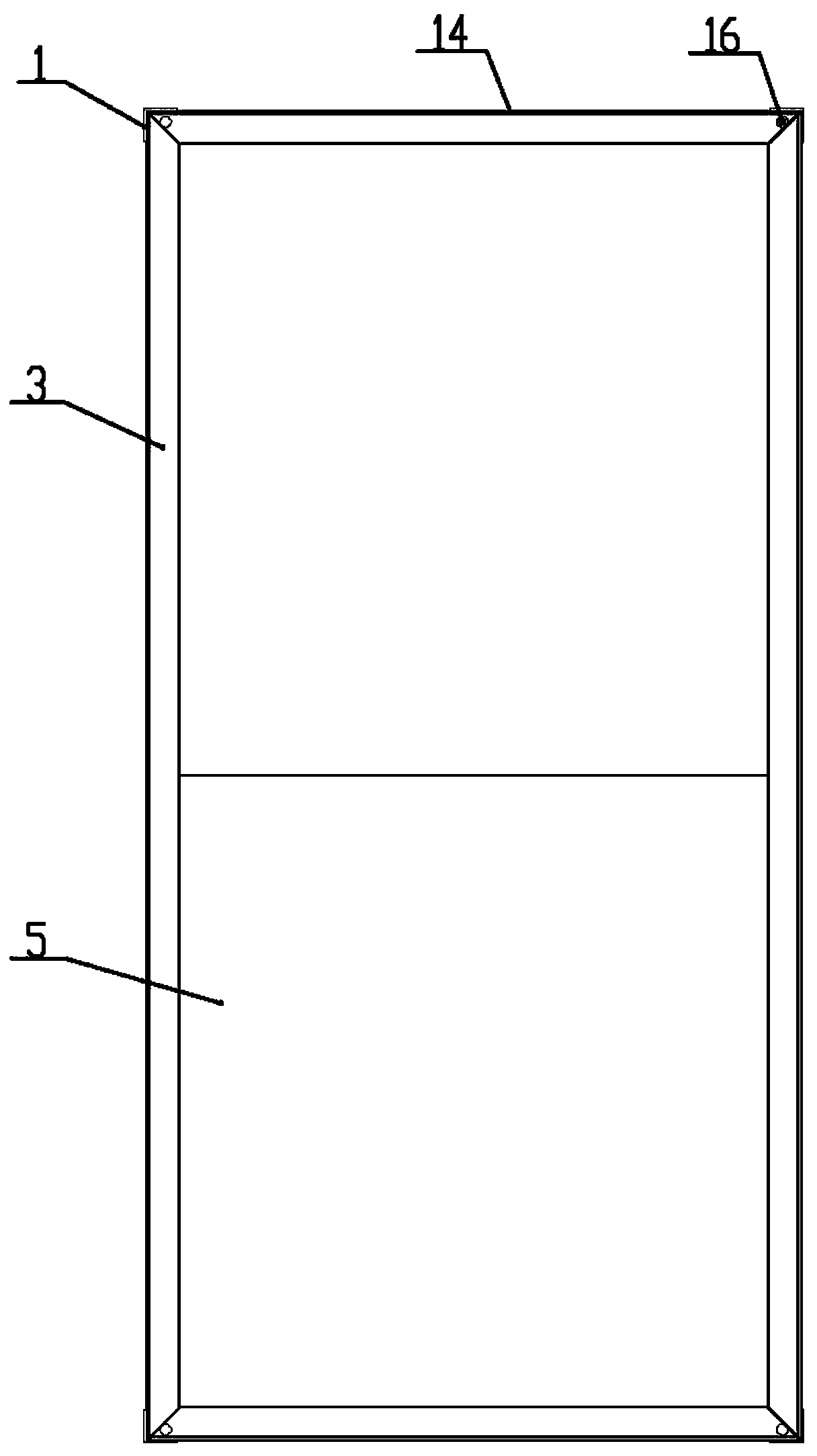

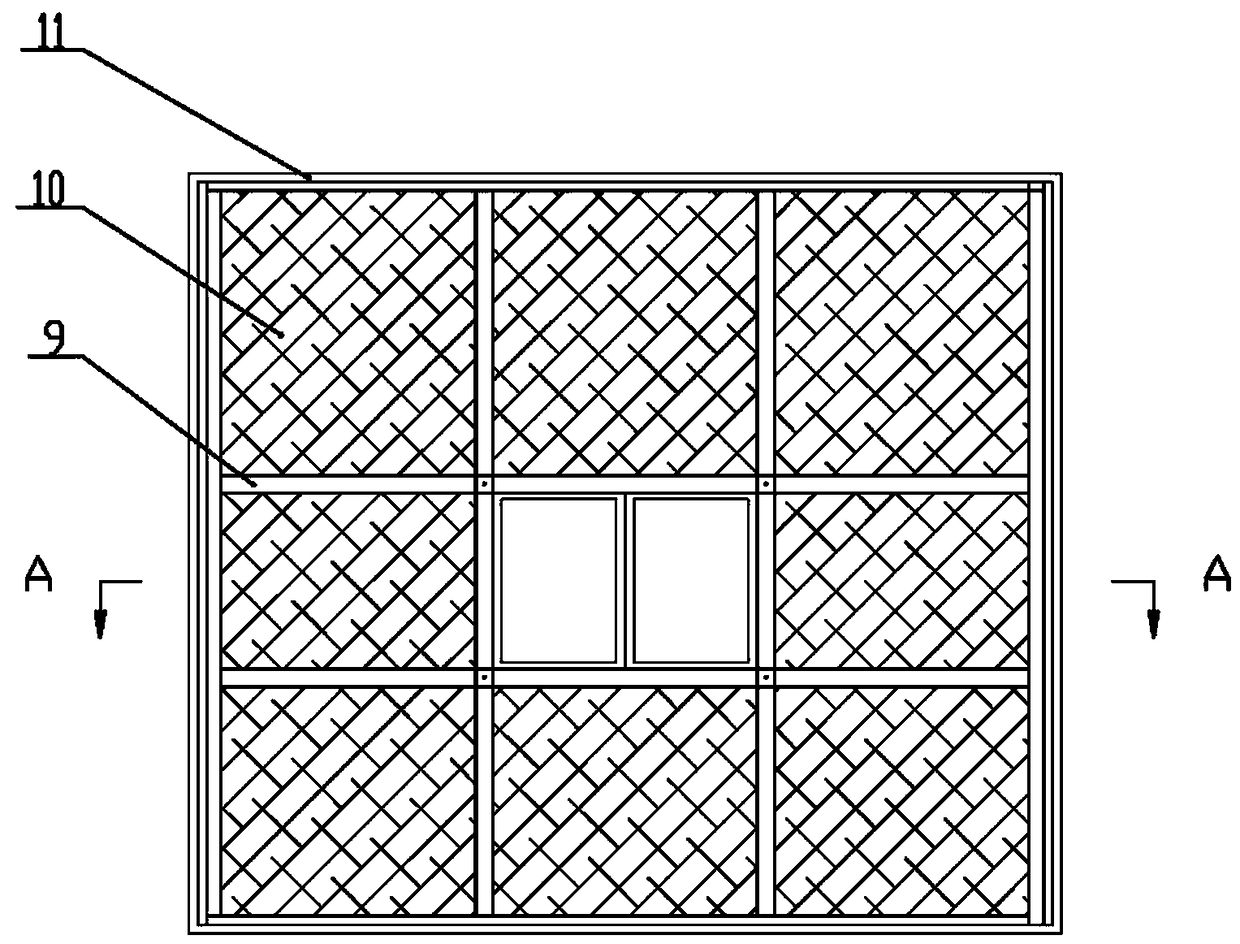

[0027] Example: such as Figures 1 to 10 As shown, a modular steel structure house suitable for areas with high seismic intensity includes frame columns 1 located at the four edges of a cuboid, bottom beams 2 connecting the bottom of the frame columns 1, and top beams 19 connecting the top of the frame columns 1, Frame columns 1, bottom beams 2, and top beams 19 are detachably connected to form a frame body. The side of the frame body is equipped with wall panels 3 using detachable connectors. The bottom surface of the frame body is equipped with a bottom plate 4 using detachable connectors. The top surface is installed with a top plate 5 using detachable connectors, and bottom purlins 6 are arranged between at least one set of opposite bottom beams 2 , and the bottom plate 4 is located above the bottom purlins 6 . The frame column 1, the bottom beam 2 and the top beam 19 of the present invention are all detachably connected, while the wall panel 3 is connected to the frame bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com