Large working resistance leading hydraulic bracket for return airway

A technology of working resistance and hydraulic support, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve problems such as pedestrian passage and ventilation space compression, column damage, and support strength difficult to exceed 1Mpa, etc., to ensure normal production Effects of propulsion, large working resistance and support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

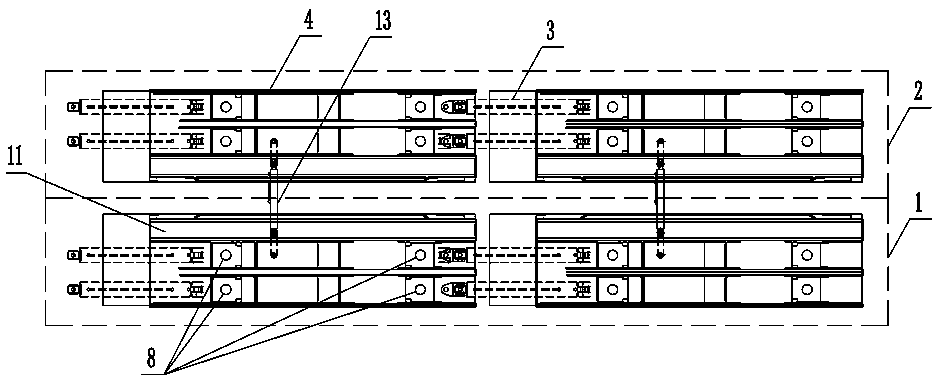

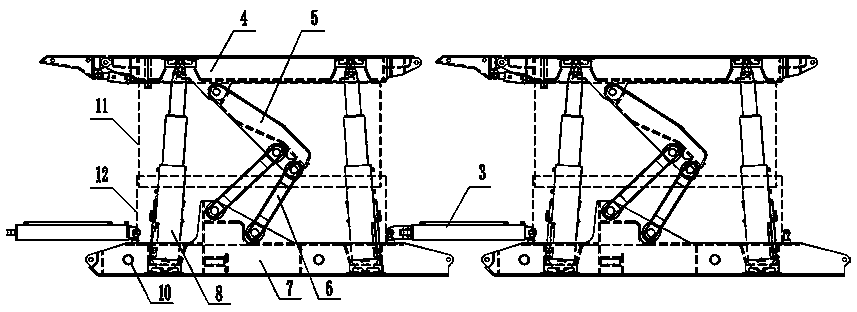

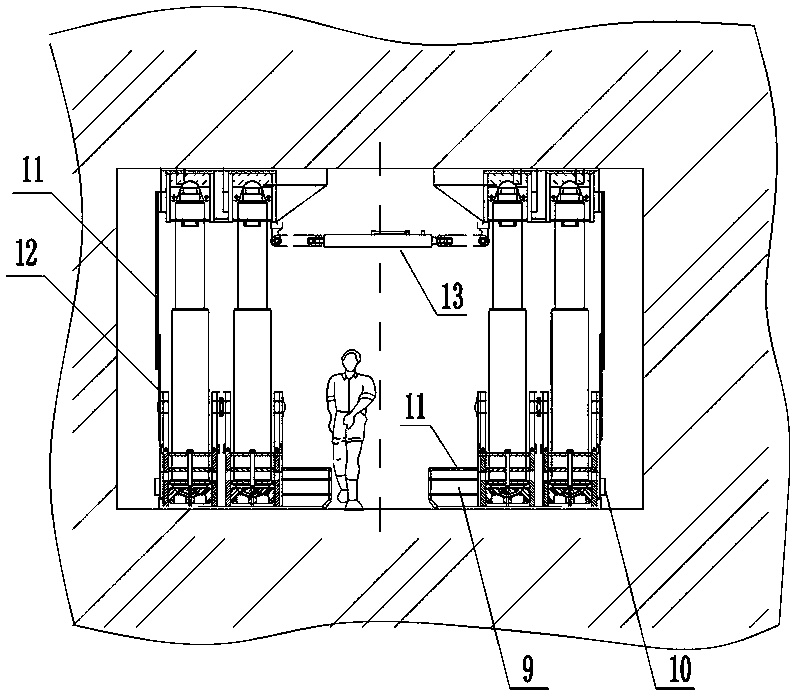

[0023] Such as Figure 1-5 As shown, the large working resistance leading hydraulic support for the return airway according to the present invention includes two support units 1, 2 arranged side by side at intervals, the two support units 1, 2 have the same structure, and are composed of The set front bracket and the rear bracket are composed; the front bracket and the rear bracket are hinged by moving the jack 3; Telescopic upright column 8, inner bottom adjustment jack 9, outer bottom adjustment jack 10 form.

[0024] Such as figure 1 , 2 As shown, there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com